Magnetic fluid dynamic seal device and preparation method of magnetic fluid

A magnetic fluid, dynamic sealing technology, applied in the direction of engine sealing, encapsulation/impregnation, inductance/transformer/magnet manufacturing, etc., can solve the problems of high linear speed, long life and large gap at the same time, and achieve low viscosity and high Magnetic saturation strength, resistance to external pressure, and the effect of improving sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

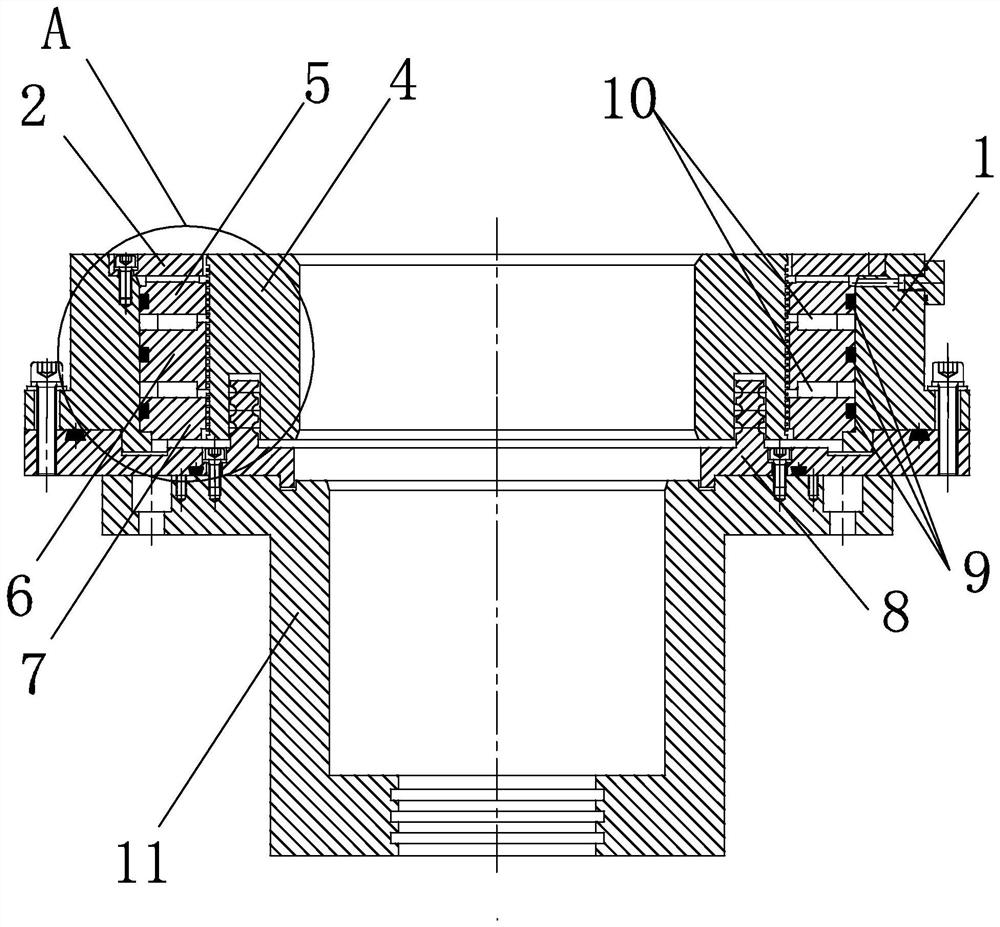

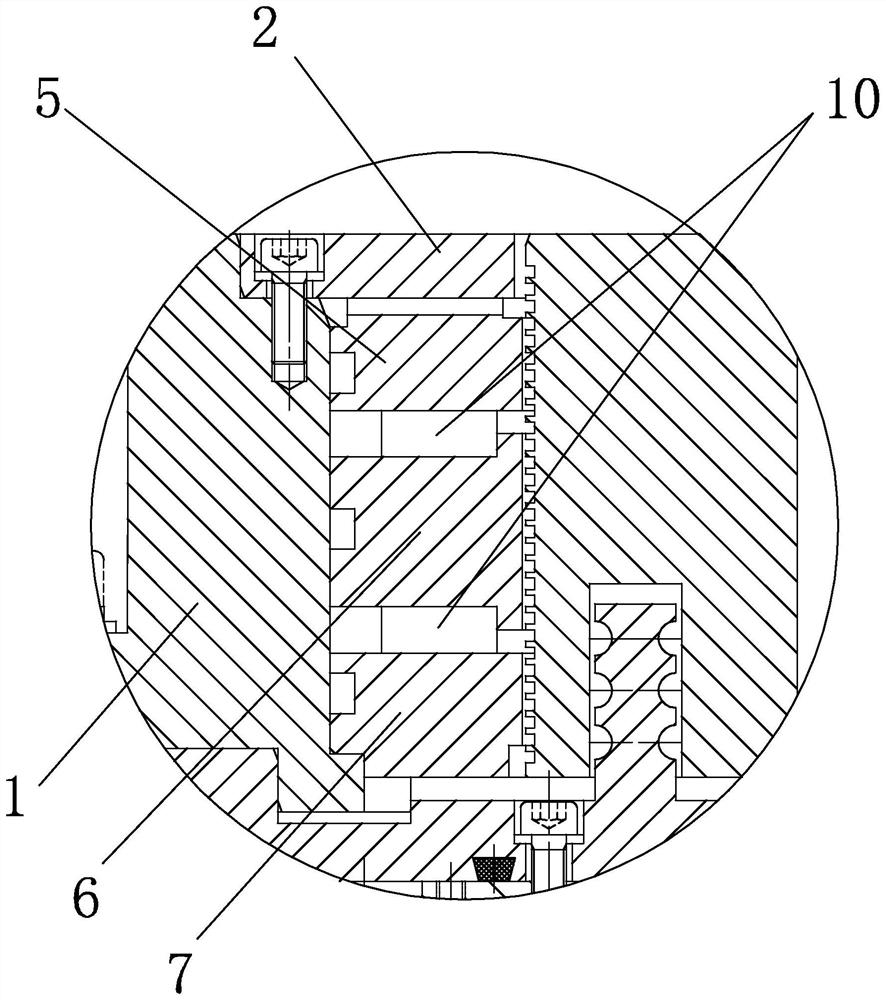

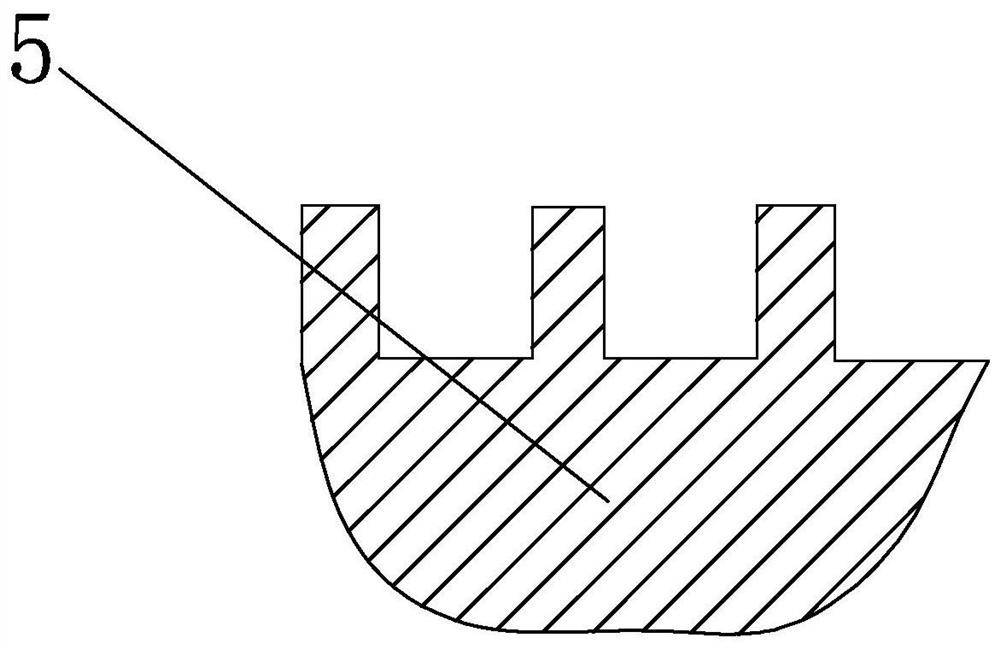

[0018] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a magnetic fluid dynamic sealing device includes a housing 1, a gland 2, a hollow magnetic seat 4, a hollow base 8 and a plurality of sealing rings 9, the shell 1 is made of non-magnetic stainless steel material, the hollow magnetic The seat 4 is installed on the hollow base 8. The hollow base 8 is made of non-magnetic material or weakly magnetic material. The housing 1 is set on the outside of the hollow magnetic permeable base 4 and installed on the hollow base 8. The inner wall of the housing 1 and the hollow There is a space between the outer walls of the magnetic permeable seat 4, which also includes the upper pole shoe 5, the middle pole shoe 6, the lower pole shoe 7, magnetic fluid, bearing housing 11 and two NdFeB magnets 10, and the hollow base 8 is installed On the bearing housing 11, the lower pole piece 7, one NdFeB magnet 10 of the two NdFeB magnets 10, the middle pole...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination Figure 1 to Figure 2To describe this embodiment, the upper pole piece 5 , the middle pole piece 6 and the lower pole piece 7 of this embodiment are all made of magnetically permeable materials. Such arrangement prevents leakage of magnetic lines of force. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 1 to Figure 2 The present embodiment will be described. The thicknesses of the upper pole piece 5 and the lower pole piece 7 in this embodiment are smaller than the thickness of the middle pole piece 6 . In this way, three sets of magnetically conductive pole pieces are used, the upper and lower pole pieces are 30mm thick and 30mm wide, and the middle layer is 40mm wide and 30mm wide. It can absorb 95% of the distribution of magnetic force lines, which improves the sealing ability and prevents the leakage of the magnetic field. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com