Construction method and structure of steel sheet pile cofferdam in tidal zone of sea area

A steel sheet pile cofferdam and construction method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of fine sand loss, high construction cost, and low turnover work efficiency, so as to ensure the thickness of the back cover and the structure of the cofferdam Reasonable and ensure the effect of the quality of the back cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

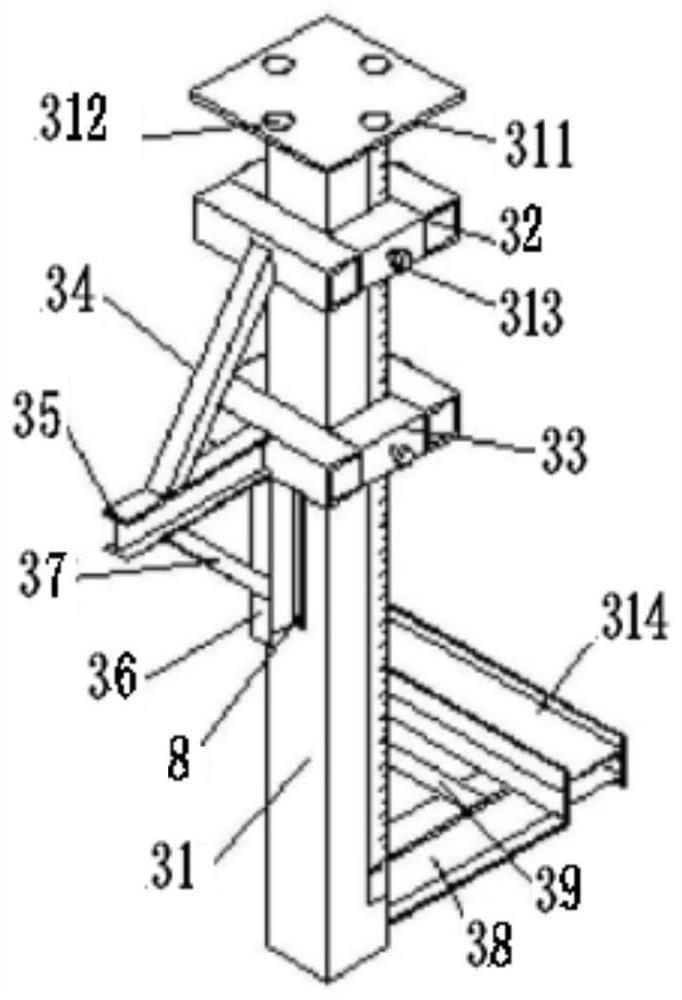

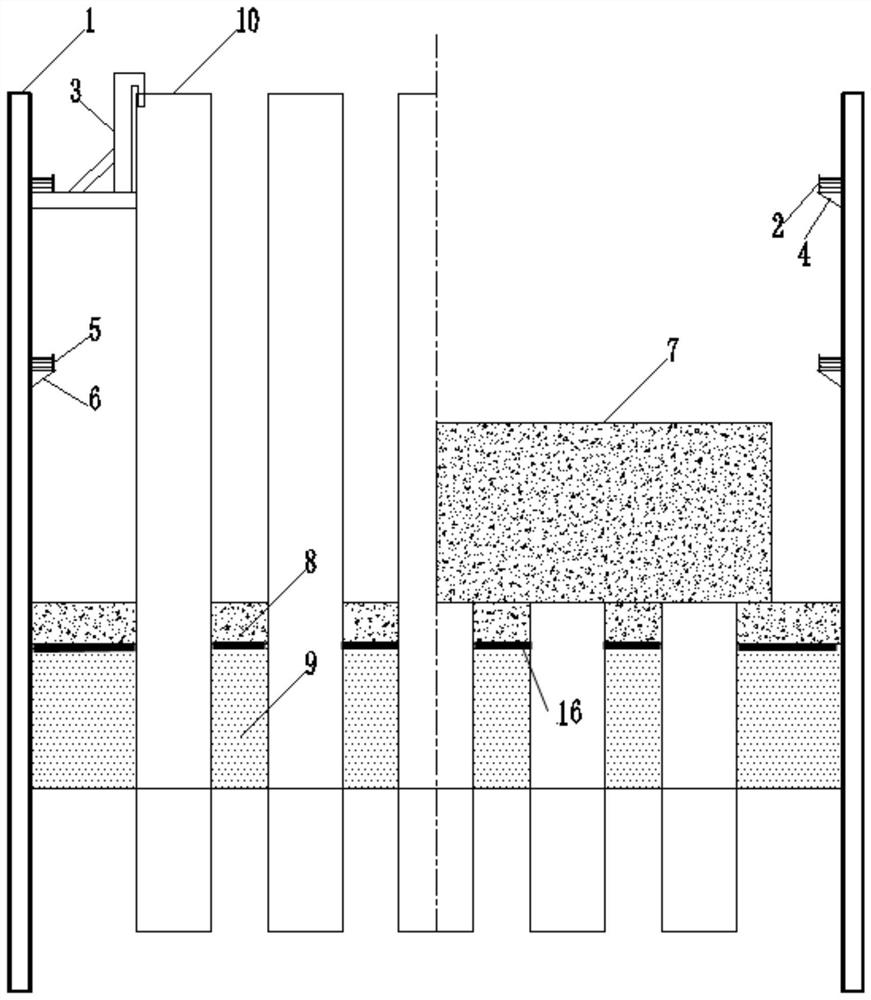

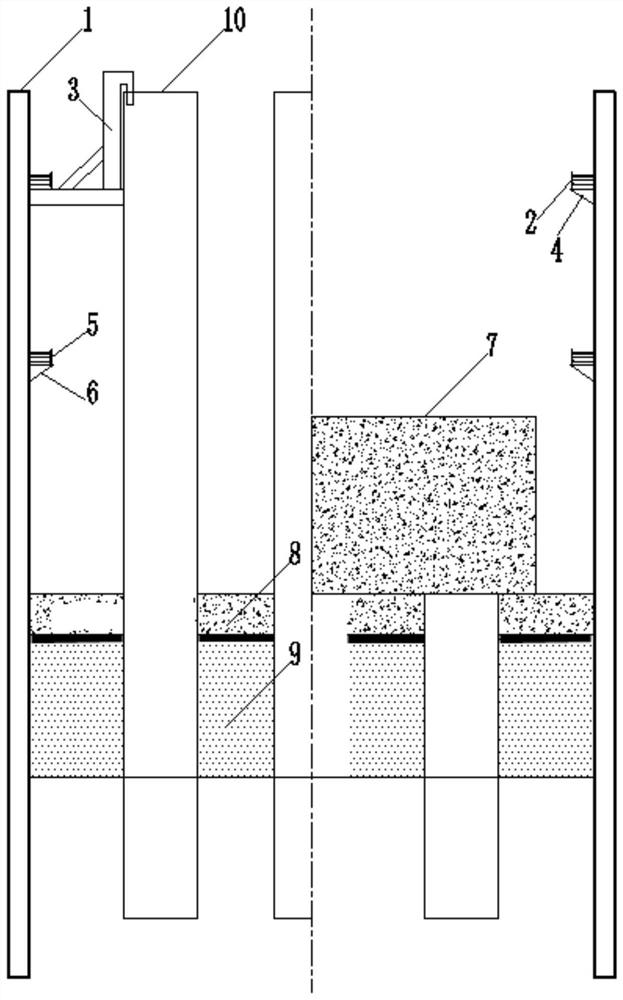

[0035] The invention provides a construction method for steel sheet pile cofferdams in tidal areas of the sea, referring to Figure 1 to Figure 7 , including the following steps:

[0036] (1) Determination of the elevation of the internal support system: according to the stratum and water level where the steel sheet pile cofferdam is located, determine the elevation of the internal support system of the steel sheet pile cofferdam; When designing the elevation of the internal support system of the cofferdam, the internal support system of the first layer is controlled at 2m below the highest tide water level, and the elevation is +3.5m; the elevation of the internal support system of the second layer is controlled at the top surface of cap 7 Above 1m, the elevation is +1.0m; the distance between the support system of the first floor and the second floor is 2.5m, control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com