Environment-friendly waste rubber tire cracking device and method

A technology of waste rubber and cracking equipment, which is applied in special forms of dry distillation, preparation of liquid hydrocarbon mixture, coke oven, etc. It can solve the problems of uniform cutting, failure to achieve uniform heating of tire raw materials, and failure to achieve crushed tires, etc., to achieve even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

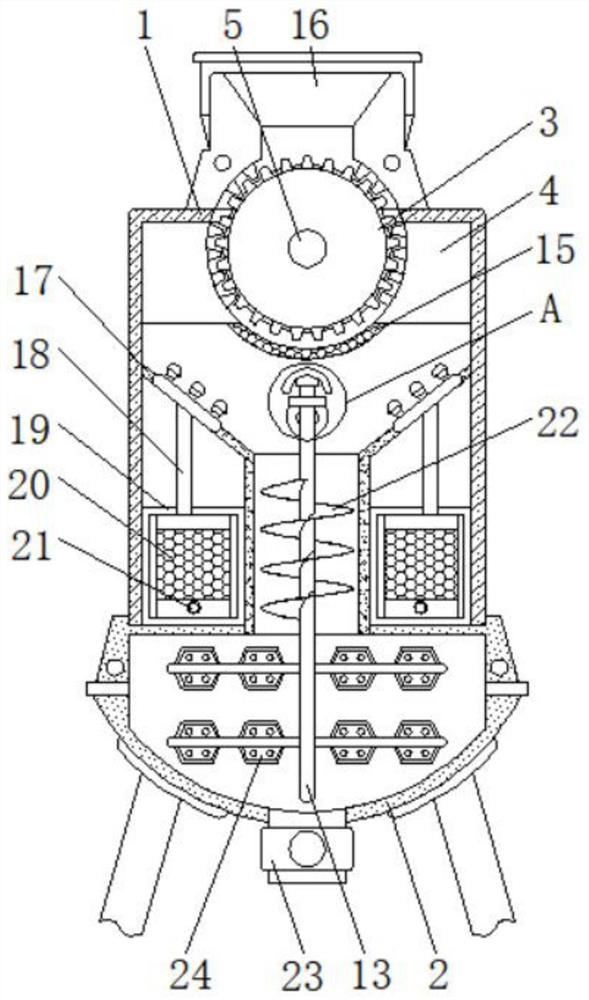

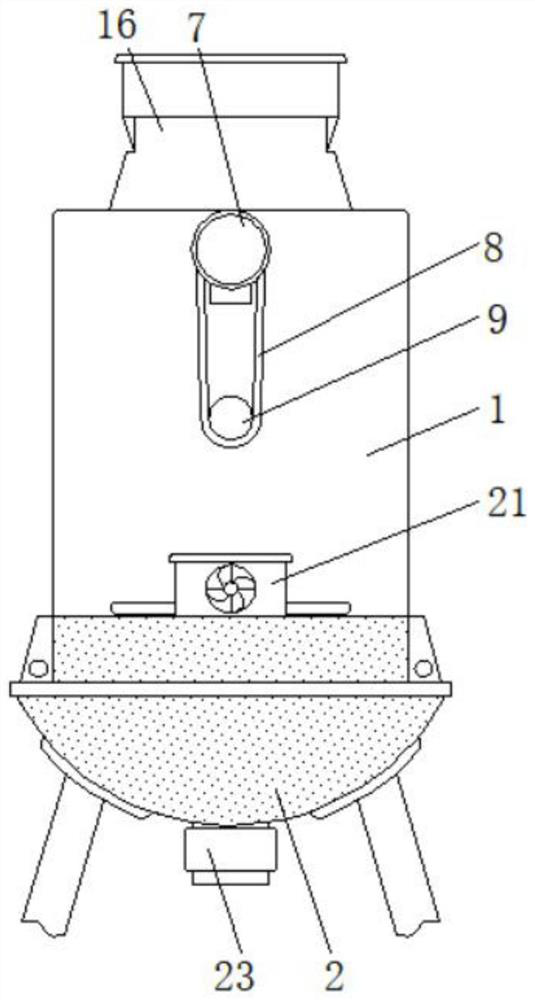

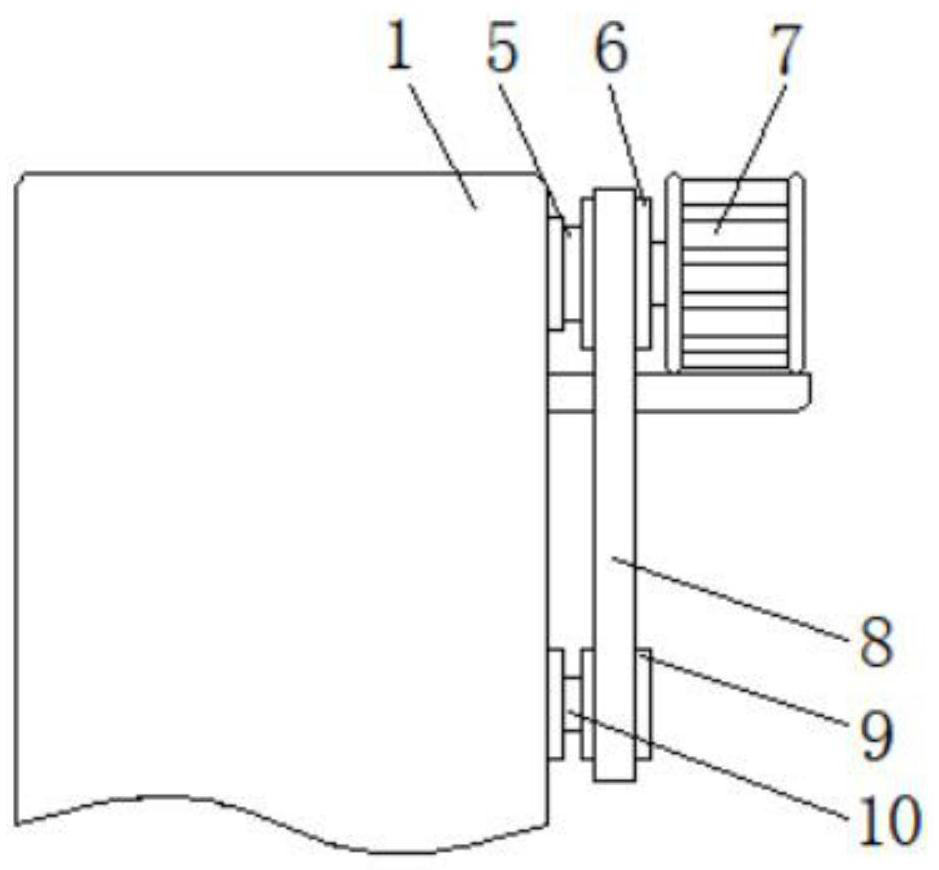

[0031] Such as Figure 1-4 As shown, the present invention provides a technical solution: an environment-friendly cracking device for waste rubber tires, comprising a box body 1, a cracking heating chamber 2 is arranged on the lower surface of the box body 1, and a crushing roller 3 is arranged in the box body 1 to crush The roller 3 is clamped on the outer wall of the first rotating shaft 5, and the first rotating shaft 5 is sleeved in the bearing clamped on the back of the box body 1. One end of the back of the first rotating shaft 5 is fixedly connected to the output shaft of the motor 7 through the driving wheel 6, and the motor 7. The front of the fuselage is fixedly connected to the back of the box body 1. The driving wheel 6 is connected to the driven wheel 9 through the belt 8. The front of the driven wheel 9 is fixedly connected to the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com