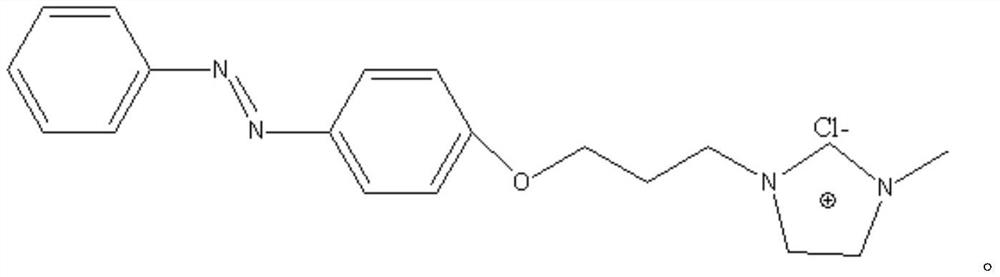

Cellulose-soluble photoresponsive ionic liquid and its preparation method and application

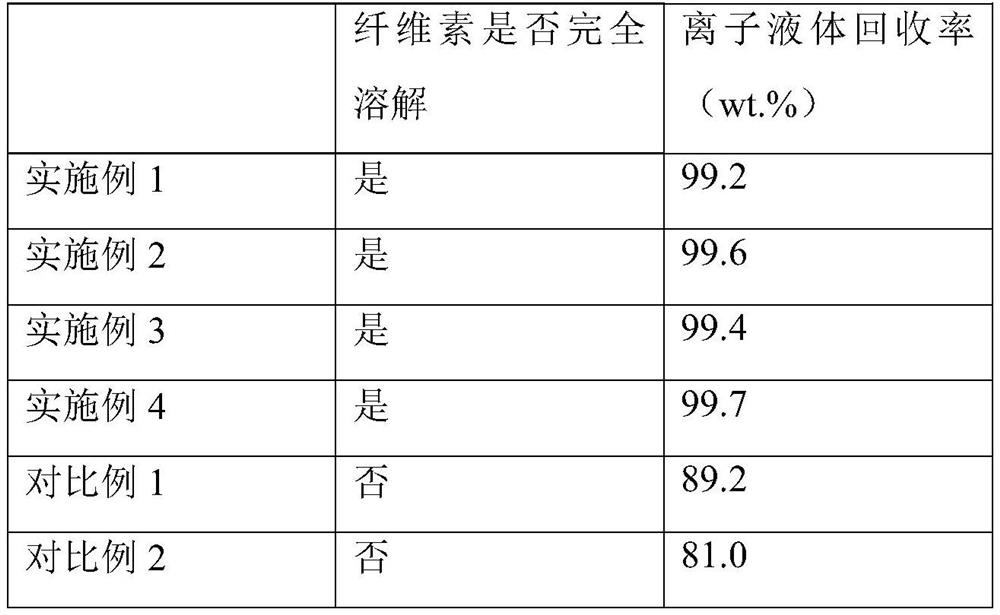

A technology for dissolving cellulose and ionic liquids, which is applied in the field of light-responsive ionic liquids and their preparations, and can solve the problems of difficult recovery and reuse of ionic liquids, complicated methods for recovering ionic liquids, and limitations in the use temperature of ionic liquids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

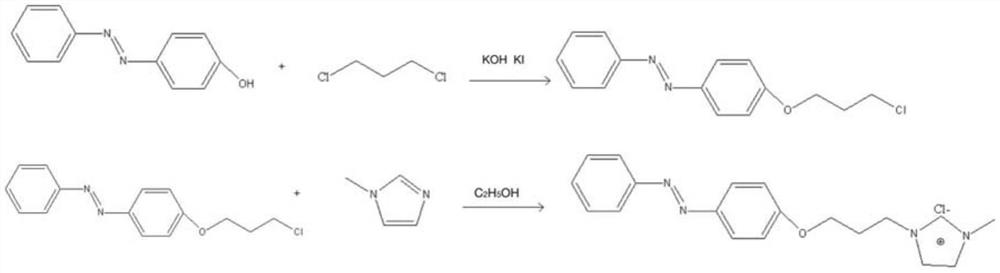

[0064] The preparation method of the cellulose-soluble light-responsive ionic liquid comprises the following steps:

[0065] (1) 2.0g KOH, 0.297g KI catalyst, 4.00ml 1,3-dichloropropane and 10ml acetone were added to a 100ml three-necked flask under nitrogen protection. Open the oil bath pot for magnetic stirring and heating, set the temperature to 60°C, and set the stirring rate to 180 r / min. The temperature of the reaction vessel was maintained at 60-65°C, the stirring rate was constant, and the reflux phenomenon was waited for.

[0066] (2) After stable reflux occurs, 2.1 g of 4-hydroxyazobenzene is weighed and dissolved in 20 ml of acetone, and slowly added dropwise for 1 h. After the dropwise addition, the reaction was carried out at the current temperature and rotation speed for 24h.

[0067] (3) After the reaction is completed, the solution is filtered while hot, the filter residue is washed with acetone to obtain a washing solution, the collected filtrate and washing...

Embodiment 2

[0078] The preparation method of the cellulose-soluble light-responsive ionic liquid comprises the following steps:

[0079] (1) 1.889g KOH, 0.287g KI catalyst, 4.00ml 1,3-dichloropropane and 10ml acetone were added to a 100ml three-necked flask under nitrogen protection. Open the oil bath pot for magnetic stirring and heating, set the temperature to 65°C, and set the stirring rate to 190 r / min. The temperature of the reaction vessel was maintained at 60-67°C, the stirring rate was constant, and the reflux phenomenon was waited for.

[0080] (2) After stable reflux occurs, weigh 2.517 g of 4-hydroxyazobenzene, dissolve it in 18 ml of acetone, and slowly add it dropwise for 1 h. After the dropwise addition, the reaction was carried out at the current temperature and rotation speed for 24h.

[0081] (3) After the reaction is completed, the solution is filtered while hot, and the filter residue is washed with acetone to obtain a washing solution. The collected filtrate and wash...

Embodiment 3

[0089] The preparation method of the cellulose-soluble light-responsive ionic liquid comprises the following steps:

[0090] (1) 1.903 g of KOH, 0.201 g of KI catalyst, 4.5 ml of 1,3-dichloropropane and 12 ml of acetone were added to a 100 ml three-necked flask under nitrogen protection. Open the oil bath pot for magnetic stirring and heating, set the temperature to 62°C, and set the stirring rate to 185 r / min. The temperature of the reaction vessel was maintained at 60-65°C, the stirring rate was constant, and the reflux phenomenon was waited for.

[0091] (2) After stable reflux occurs, weigh 2.713 g of 4-hydroxyazobenzene, dissolve it in 20 ml of acetone, and slowly add it dropwise for 1 hour. After the dropwise addition, the reaction was carried out at the current temperature and rotation speed for 24h.

[0092] (3) After the reaction is completed, the solution is filtered while hot, the filter residue is washed with acetone to obtain a washing solution, the collected fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com