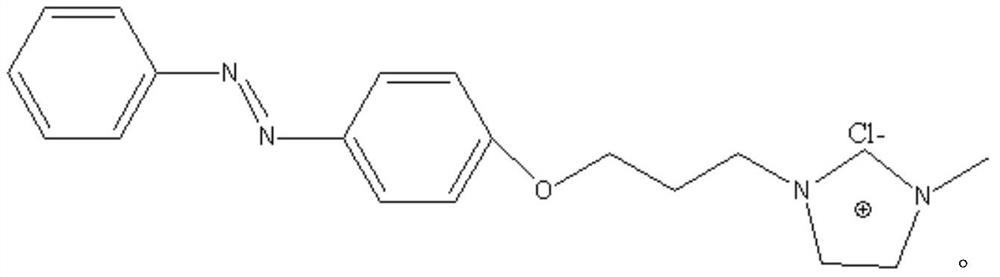

Photoresponse ionic liquid capable of dissolving cellulose as well as preparation method and application thereof

A technology for dissolving cellulose and ionic liquids, which is applied in the field of light-responsive ionic liquids and their preparation, can solve the problems of limited operating temperature of ionic liquids, complex methods of recovering ionic liquids, and difficulty in recycling and reusing ionic liquids, etc., to achieve Effect of good photoisomerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

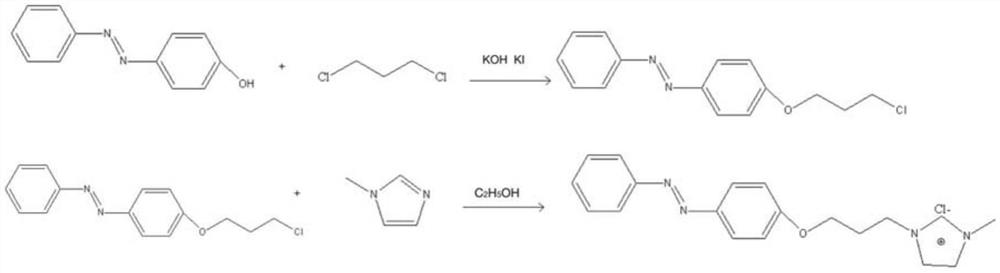

[0064] A method for preparing a cellulose-soluble photoresponsive ionic liquid, comprising the steps of:

[0065] (1) Add 2.0 g of KOH, 0.297 g of KI catalyst, 4.00 ml of 1,3-dichloropropane and 10 ml of acetone into a 100 ml three-neck flask under nitrogen protection. Turn on the oil bath for magnetic stirring and heating, set the temperature to 60°C, and the stirring rate to 180r / min. The temperature of the reaction vessel was maintained at 60-65° C., the stirring rate was constant, and the reflux phenomenon was waited for.

[0066] (2) After a stable reflux occurs, weigh 2.1g of 4-hydroxyazobenzene and dissolve it in 20ml of acetone, and slowly add it dropwise for 1 hour. After the dropwise addition, maintain the current temperature and rotation speed to react for 24 hours.

[0067] (3) After the reaction is completed, the solution is filtered while it is hot, and the filter residue is washed with acetone to obtain a washing solution. The collected filtrate and washing so...

Embodiment 2

[0078] A method for preparing a cellulose-soluble photoresponsive ionic liquid, comprising the steps of:

[0079] (1) Add 1.889g of KOH, 0.287g of KI catalyst, 4.00ml of 1,3-dichloropropane and 10ml of acetone into a 100ml three-neck flask under nitrogen protection. Turn on the oil bath for magnetic stirring and heating, set the temperature at 65°C, and the stirring rate at 190r / min. The temperature of the reaction vessel was maintained at 60-67° C., the stirring rate was constant, and the reflux phenomenon was waited for.

[0080] (2) After a stable reflux occurs, weigh 2.517g of 4-hydroxyazobenzene and dissolve it in 18ml of acetone, and slowly add it dropwise for 1 hour. After the dropwise addition, maintain the current temperature and rotation speed to react for 24 hours.

[0081] (3) After the reaction is completed, the solution is filtered while it is hot, and the filter residue is washed with acetone to obtain a washing solution. The collected filtrate and washing sol...

Embodiment 3

[0089] A method for preparing a cellulose-soluble photoresponsive ionic liquid, comprising the steps of:

[0090] (1) Add 1.903g of KOH, 0.201g of KI catalyst, 4.5ml of 1,3-dichloropropane and 12ml of acetone into a 100ml three-neck flask under nitrogen protection. Turn on the oil bath for magnetic stirring and heating, set the temperature at 62°C, and the stirring rate at 185r / min. The temperature of the reaction vessel was maintained at 60-65° C., the stirring rate was constant, and the reflux phenomenon was waited for.

[0091] (2) After a stable reflux occurs, weigh 2.713g of 4-hydroxyazobenzene and dissolve it in 20ml of acetone, and slowly add it dropwise for 1 hour. After the dropwise addition, maintain the current temperature and rotation speed to react for 24 hours.

[0092] (3) After the reaction is completed, the solution is filtered while it is hot, and the filter residue is washed with acetone to obtain a washing solution. The collected filtrate and washing solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com