Corrugated carton board tilter

A corrugated cardboard box and turning machine technology, which is applied in mechanical equipment, mechanical processing/deformation, spring/shock absorber, etc., can solve the problem of uneven elasticity, decreased elasticity and extensibility of corrugated cardboard, and the collapse of corrugated cardboard is easy to be damaged and other problems to achieve the effect of avoiding irregular collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

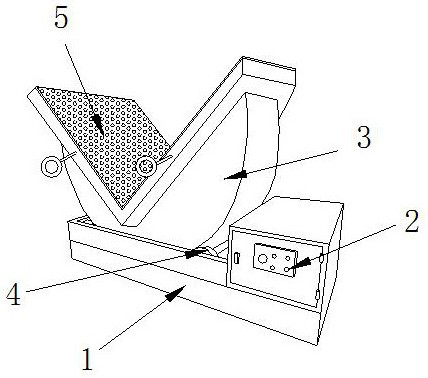

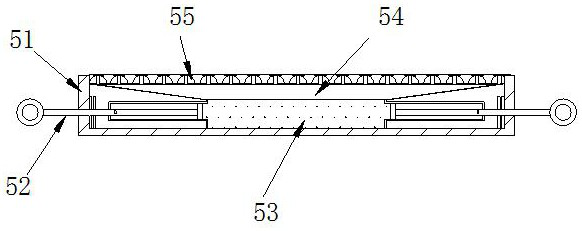

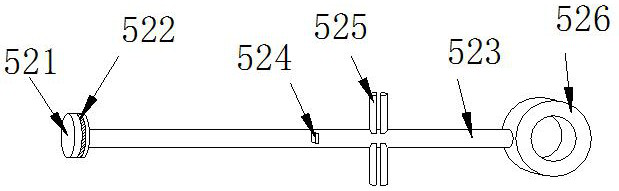

[0025] see Figure 1-Figure 5 , the specific embodiments of the present invention are as follows: a corrugated board turning machine, its structure includes a base 1, a control box 2, a turning block 3, a rolling shaft 4, and an operating table 5, and the top of the base 1 is welded to the bottom of the control box 2 , the bottom of the turning block 3 is movably engaged with the top of the base 1 through the rolling shaft 4, and the bottom of the operating table 5 is embedded and connected with the top of the turning block 3; the operating table 5 includes a casing 51, a pressure device 52, and an air chamber 53 , air inlet 54, fixed buffer block 55, the inner wall of the housing 51 is welded to the bottom of the pressure device 52, the side of the gas chamber 53 is transitionally matched with the side of the pressure device 52, and the bottom of the gas chamber 53 is embedded in the housing 51 bottom inner wall, the bottom of the air suction port 54 is embedded and connected...

Embodiment 2

[0031] see Figure 6-Figure 7 The specific embodiment of the present invention is as follows: the buffer seat 551 includes an outer membrane B1, a connecting layer B2, a fastening wire B3, and a fixing plate B4, the inner wall of the outer membrane B1 is embedded and connected to the top of the connecting layer B2, and the connecting layer The bottom of B2 is connected to the top of the fixed plate B4 through the fastening wire B3. The fastening wire B3 is made of nylon fiber, which has strong toughness and is not easy to break. The outer membrane B1 is made of PVC film, which is relatively soft and easy to deform, which is conducive to timely receiving pressure. Deformation occurs to avoid excessive compression of corrugated cardboard.

[0032]Wherein, the air pressure pipe 553 includes an anti-suckback plate C1 and a pipe wall C2, the bottom of the anti-suckback plate C1 is movably engaged with the inner layer of the pipe wall C2, and the pipe wall C2 is made of a PVC hose, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com