Device for recycling spray cans

A technology for aerosols and storage boxes, which is applied in the field of recycling devices for aerosol cans, can solve the problems of increased difficulty in recycling, high risk of manual operation, low efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

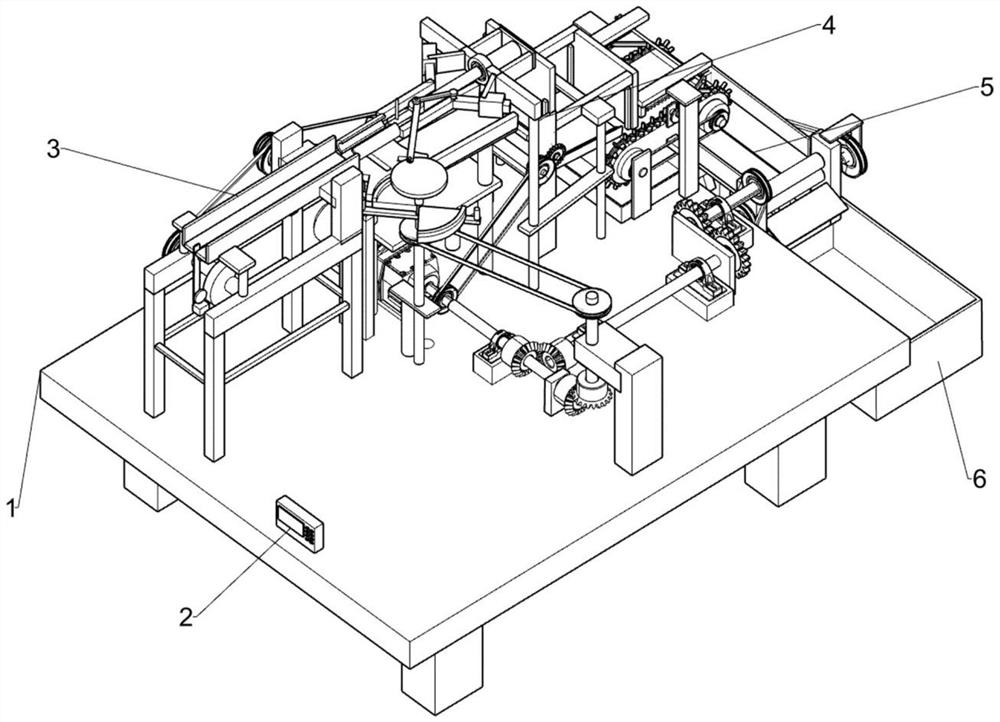

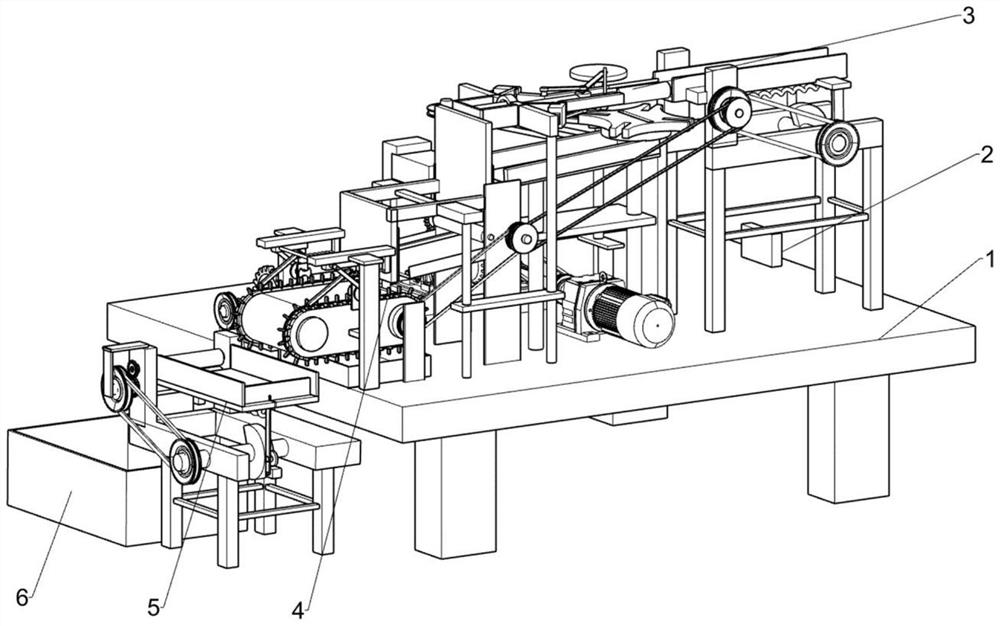

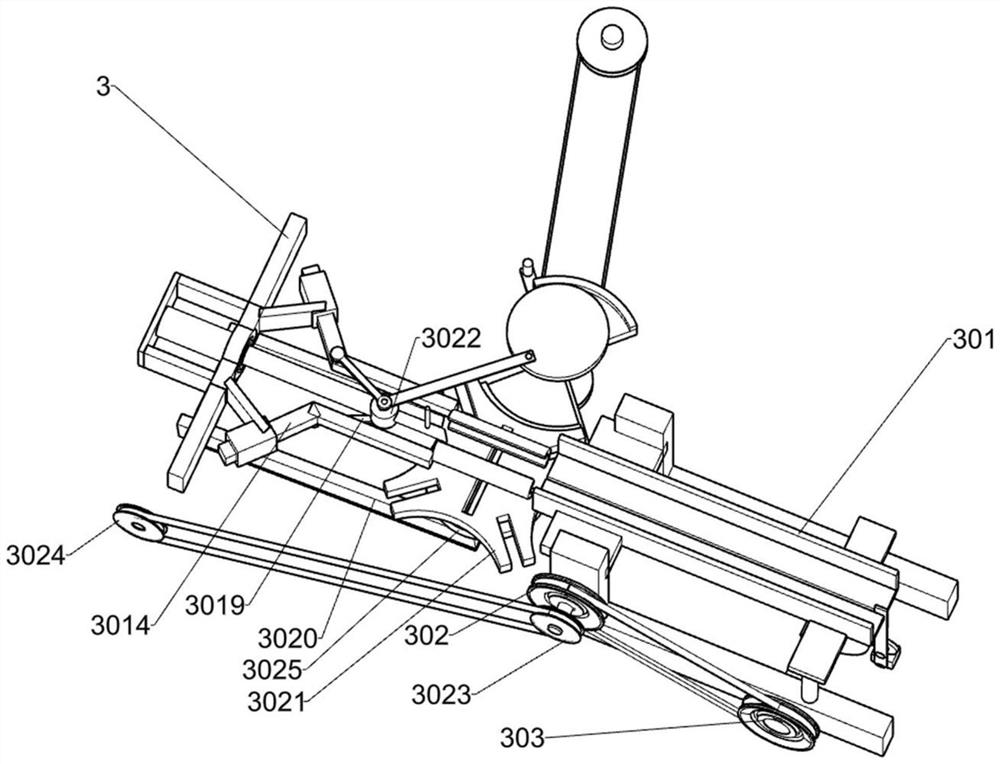

[0031] A recycling device for aerosol cans, such as Figure 1-9 As shown, it includes a bottom frame 1, a controller 2, a drilling inflation mechanism 3, a grinding and cutting mechanism 4, a skin compression mechanism 5 and a storage box 6; a controller 2 is arranged above the bottom frame 1; The hole inflation mechanism 3, the grinding and cutting mechanism 4 are connected with the skin compression mechanism 5; the drilling inflation mechanism 3 is connected with the grinding and cutting mechanism 4; the drilling inflation mechanism 3 is connected with the skin compression mechanism 5; the grinding and cutting mechanism 4 is connected with the skin compression mechanism The mechanisms 5 are connected; the storage box 6 is arranged at the angle between the underframe 1 and the skin compression mechanism 5 .

[0032] When in use, first set the chassis 1 in a stable working environment, then turn on the power to the device, and at the same time coordinate the peripheral conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com