A live working method for vertically arranged conductors

A live operation and vertical arrangement technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the labor intensity of operators, reducing the safety distance between conductors, endangering the safety of operators, etc. The effect of walking and obstacle-surmounting ability and improving climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

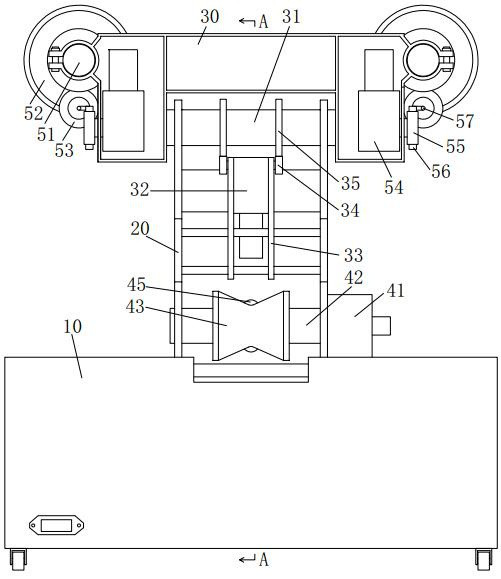

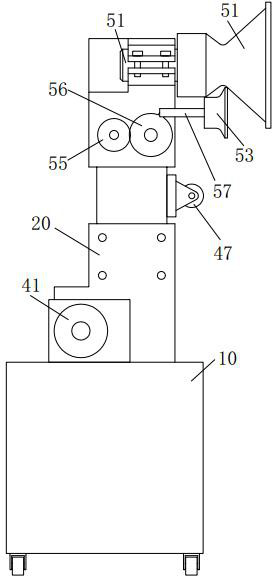

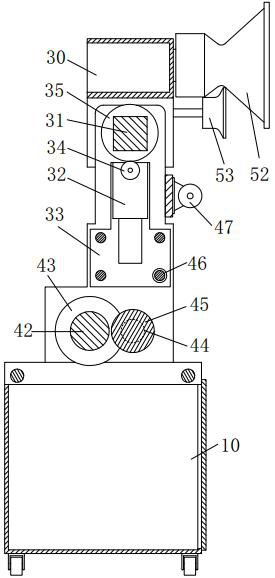

[0028] refer to Figure 1 to Figure 4

[0029] A live working method for vertically arranging wires to lead out, comprising the following steps:

[0030] (1) Use the drone pilot to control the drone to the ground wire and the wire below the working phase in stages, and throw out the guide wire;

[0031] (2) The ground operator adjusts the load of the counterweight truck according to the weight of the operator, material and tools of the outgoing line;

[0032] (3) The ground operator pulls the insulating rope through the guide wire, so that the end of the insulating rope crosses the wire and returns to the ground, so that one end of the insulating rope is fixedly connected to the ground, and the backup protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com