Nondestructive testing equipment for anti-floating anchor rod and construction method

An anti-floating anchor, non-destructive testing technology, applied in measuring devices, infrastructure engineering, using stable tension/pressure to test the strength of materials, etc. The problems of increasing difficulty in construction have achieved the effects of reducing potential safety hazards, reasonable grading loading value, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

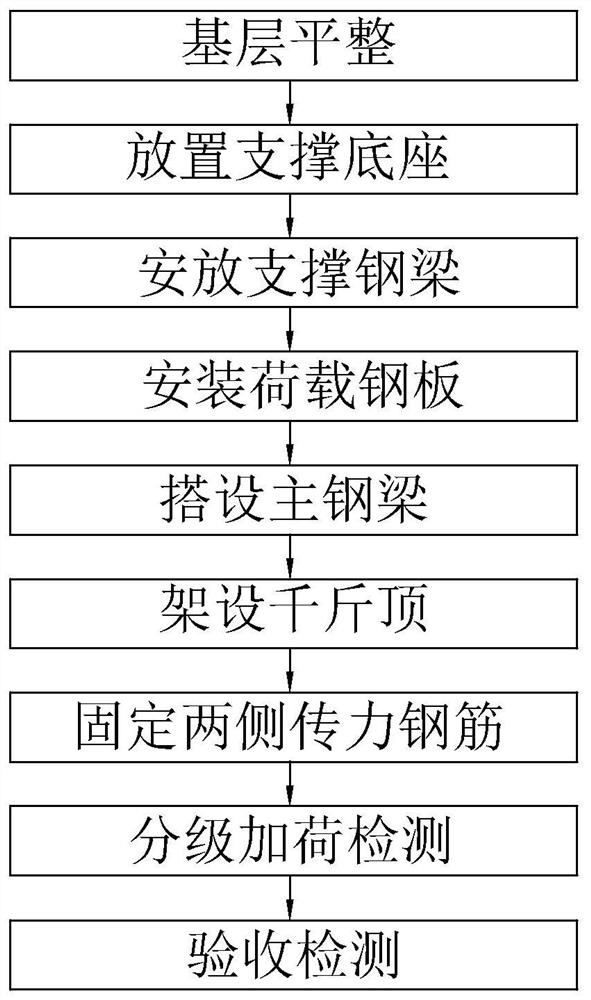

[0044] The following is attached Figure 1-2 The application is described in further detail.

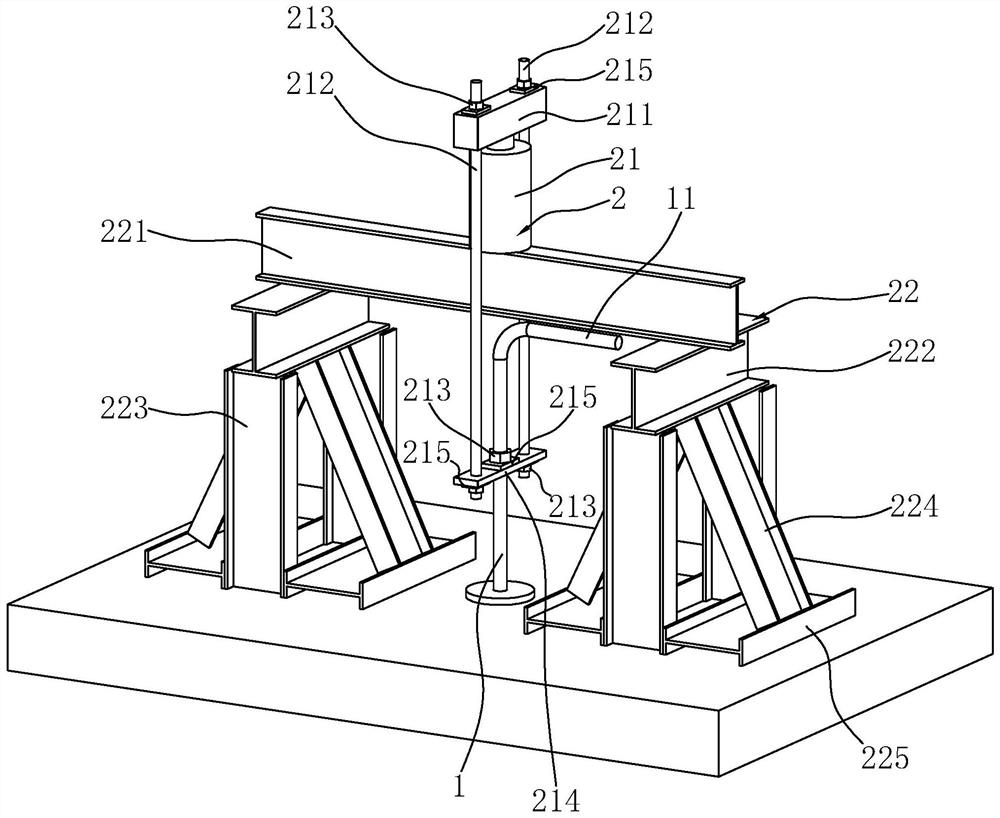

[0045] The embodiment of the present application discloses a non-destructive testing device for an anti-floating anchor. refer to figure 1 , a kind of non-destructive testing equipment for anti-floating anchors, including the main reinforcement 1 of the anchor rod to be tested installed on the ground, and the upper end of the main reinforcement 1 of the anchor rod has a 90-degree hook steel bar 11; the main reinforcement 1 of the anchor rod is provided with a The supporting detection mechanism 2 for the detection of the pull-out bearing capacity of the main reinforcement 1.

[0046] refer to figure 1 The jacking detection mechanism 2 includes a jack 21 arranged on the upper side of the main reinforcement of the anchor rod 1. The jack 21 is vertically arranged with the horizontal plane. Pressure gauge (not shown in the figure); a support assembly 22 for supporting the jack 21 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com