Optical fiber axial nondestructive on-line detection device and method

A detection device and detection method technology, applied in the direction of measuring devices, optical instrument testing, testing optical fiber/optical waveguide equipment, etc., can solve the problems of weak back-diffraction light intensity, high device precision requirements, weak anti-interference ability, etc., to achieve Versatility, high precision, and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

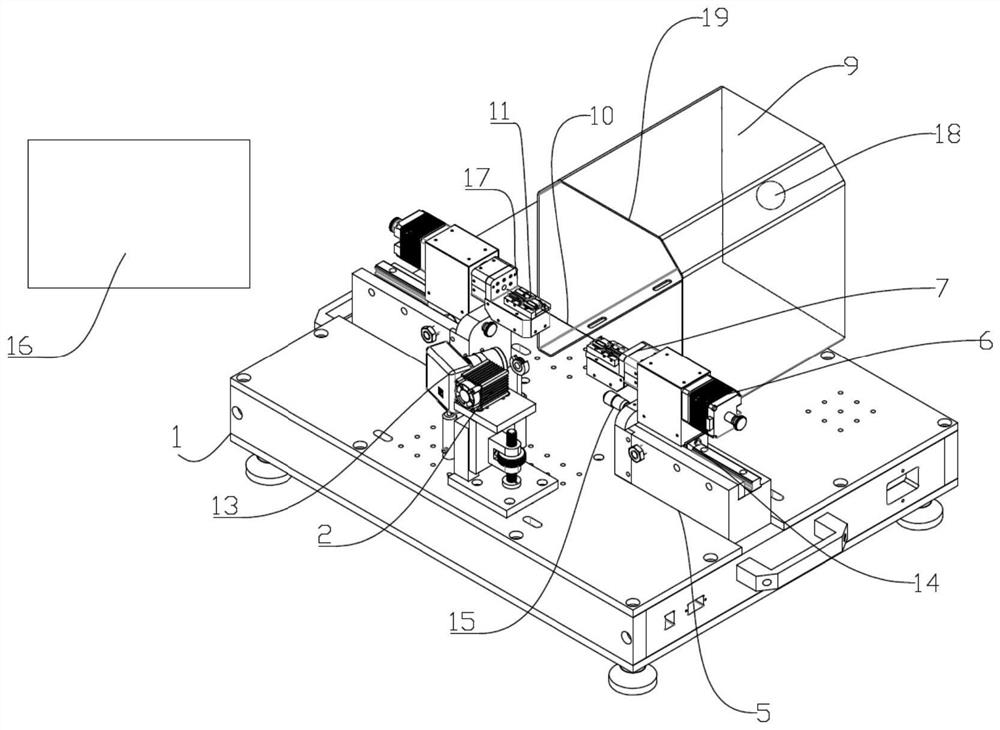

[0068] This embodiment provides an optical fiber axial non-destructive on-line detection device, through which the optical fiber axial non-destructive on-line detection is realized. Such as figure 1 As shown, the detection device of the present invention includes an image processing device 16 , an optical fiber clamp 11 , moving parts, rotating parts, an imaging screen 9 , a coherent light emitter 2 and an image recording device 13 , and the optical fiber clamp 11 is used to clamp the optical fiber 10 . The optical fiber 10 is an optical fiber from which the coating layer has been removed.

[0069] In a specific implementation process, the optical fiber clamp 11 , moving parts, rotating parts, imaging screen 9 , coherent light emitter 2 and image recording device 13 can be installed through the device platform 1 .

[0070] Install the moving parts on the device platform, the moving parts include two symmetrically arranged, each moving part includes a slide rail 5 and a slide bl...

Embodiment 2

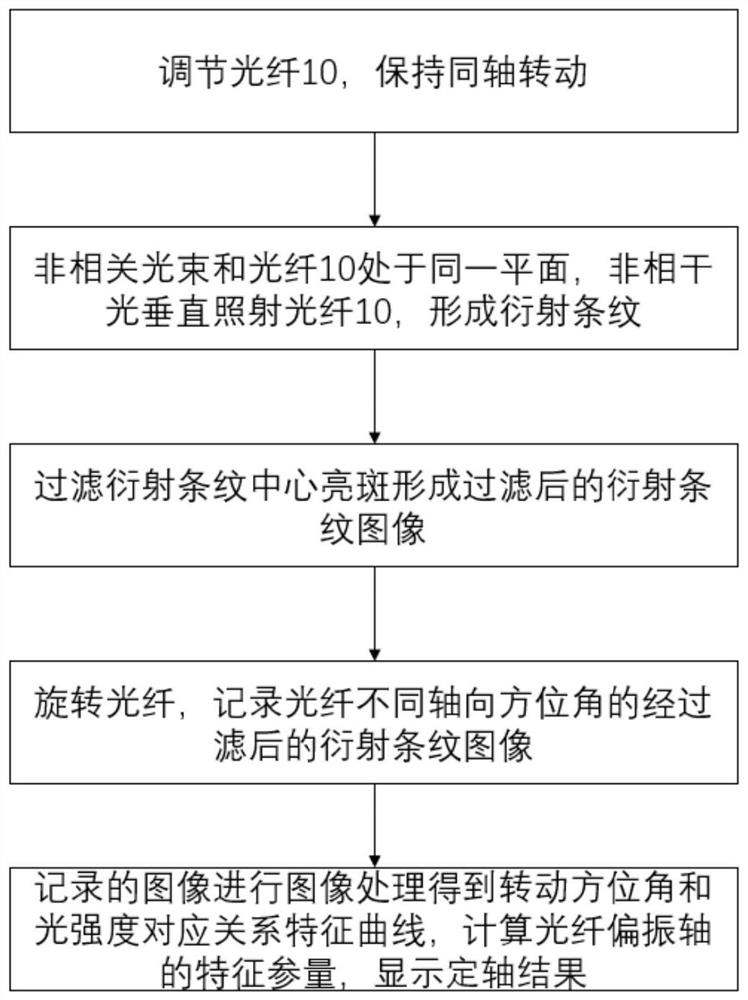

[0086] The present invention also provides an optical fiber axial non-destructive online detection method, through the method of this embodiment to realize the optical fiber axial non-destructive online detection, the method is as follows:

[0087] Such as figure 2 As shown, (1) Adjust the optical fiber 10 to keep it rotating coaxially. The coaxial rotation adjustment method is as follows: expose the tail end of one end of the optical fiber to a length of 0.5 cm to 1.0 cm, observe the operation of the tail end of the optical fiber as it rotates, and adjust to make the tail end There is no revolution at the end. Adjust the other end of the optical fiber 10 in the same way, and then keep the two ends of the optical fiber 10 at the same horizontal position;

[0088] (2) The coherent light beam and the optical fiber 10 are placed on the same plane, and the incoherent light irradiates the optical fiber 10 vertically to form diffraction fringes;

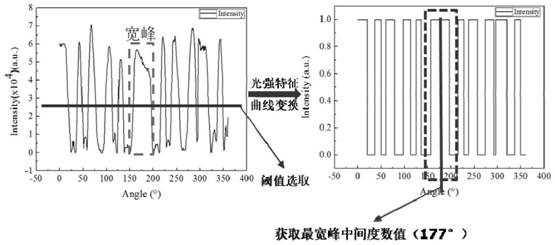

[0089] (3) Filter the central br...

Embodiment 3

[0100] This embodiment uses the device of the above-mentioned embodiment 1 to carry out the detection method of the embodiment 2, and the optical fiber 10 is selected as Figure 9 Shown is a 40-μm-diameter ultra-fine polarization-maintaining fiber with the coating removed.

[0101] The above detection methods are:

[0102] Clamp the two ends of the optical fiber 10 with the optical fiber clamp 11, and by adjusting the vertical adjustment device 7 and the horizontal adjustment device on the rotating part, the optical fiber clamps 11 at both ends are in the coaxial rotation state as much as possible; The adjustment on the surface can be observed with the aid of a microscope.

[0103] Rotate the adjustment rod 15 to push the slider 14, and use the pressure sensor to measure the tension on the optical fiber 10, and judge that the light is in a straight state according to the stable value of the tension; the adjustment rod 15 and the slider 14 are all high-precision adjustment str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com