Mechanical arm type pipe erecting machine for coal mine fully-mechanized excavation

A technology of mechanical arm and fully mechanized excavation, which is applied in the field of mechanical arm type pipe erecting machines for fully mechanized excavation in coal mines, can solve the problems of low work efficiency, single structure, difficult position adjustment, etc., and achieves increased accuracy and efficiency, improved accuracy and Efficiency, the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

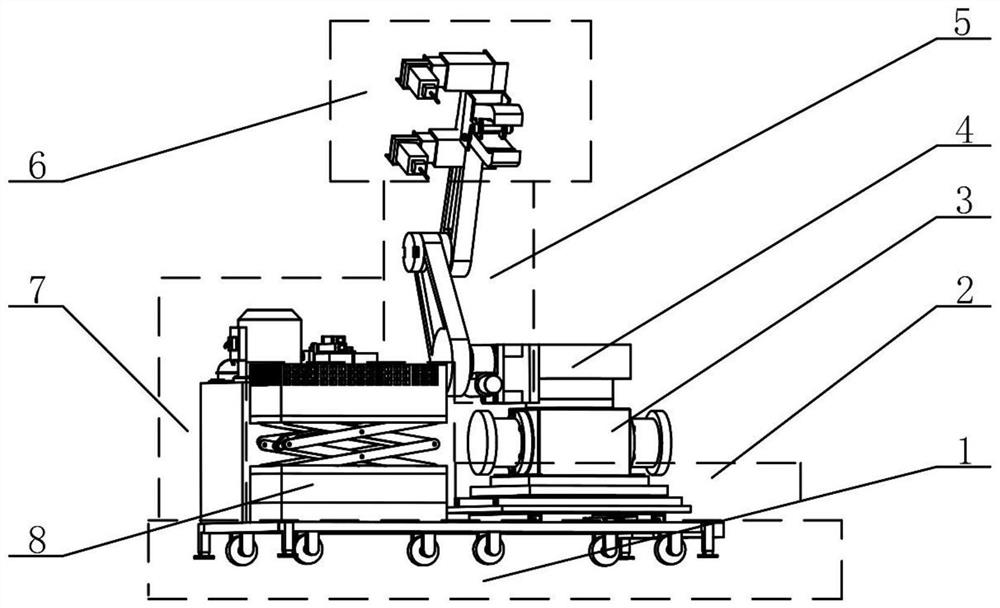

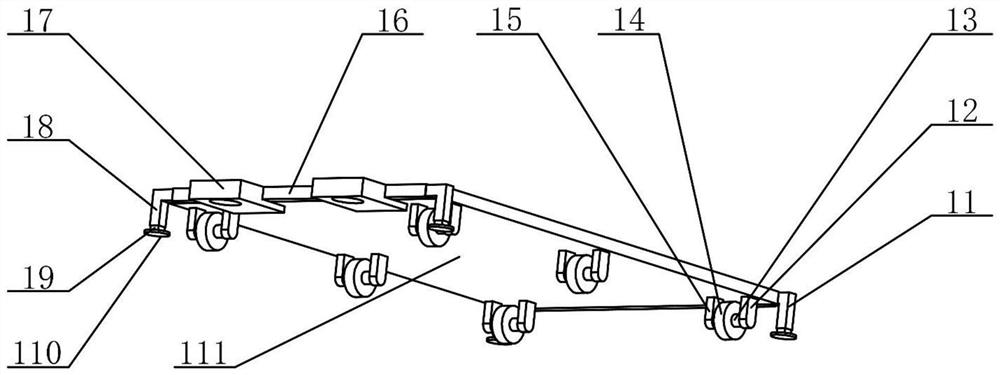

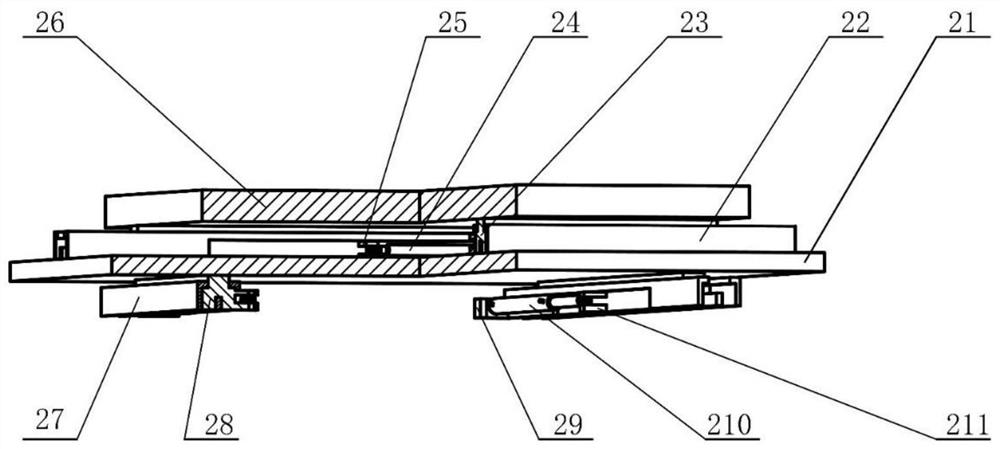

[0040] Example 1: Please refer to Figure 1-8 , the present invention provides a technical solution: a mechanical arm pipe erecting machine for coal mine comprehensive excavation, including a walking part 1, a plane adjustment part 2, a large rack and pinion hydraulic cylinder 3, an output shaft connecting sleeve 4, and a mechanical arm part 5 , the execution part 6, the power part 7, the worker's work platform part 8, the upper surface of the walking part 1 is connected with the plane adjustment part 2, the power part 7 and the worker's work platform part 8, and the left upper surface of the walking part 1 is fixedly connected with the power Part 7 and worker's work platform part 8, the plane adjustment part 2 is fixedly connected on the upper right surface of the walking part 1, the right side of the trolley bottom plate 111 is fixedly connected with the rear balance adjustment mechanism 11, and the left side of the trolley bottom plate 111 is fixedly connected with the front...

Embodiment 2

[0041] Embodiment 2: This embodiment is a further improvement of the previous embodiment. In order to facilitate the adjustment of the distance between the two rotating hole mechanisms, a slider can be added to the connecting plate 55 and pushed by a hydraulic cylinder. The first rotating hole Mechanism 66 is fixed on the increased slide block, so that the hydraulic cylinder can be used to quickly adjust the distance to meet the different types of pipelines, and complete the fast hole turning and installation.

[0042] Working principle of pipe erecting machine:

[0043] A mechanical arm type pipe erecting machine for fully mechanized excavation in coal mines. The working state at the beginning is that the first joint arm 53 and the second joint arm 54 are in the folded state, and the lifting mechanism 84 is also in the folded state.

[0044] ①Pipe lifting process: Use a tractor to pull the pipe erector to the designated working position, the large rack and pinion hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com