An Anti-Metal Vapor Deposition Structure for Hollow Cathode

A technology of metal vapor and hollow cathode, applied in the direction of utilizing plasma, machine/engine, thrust reverser, etc., can solve the problems of hollow cathode volume and weight increase, hollow cathode life failure, ceramic insulation performance decline, etc., and achieve simple structure Ease of operation, broad market application prospects, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

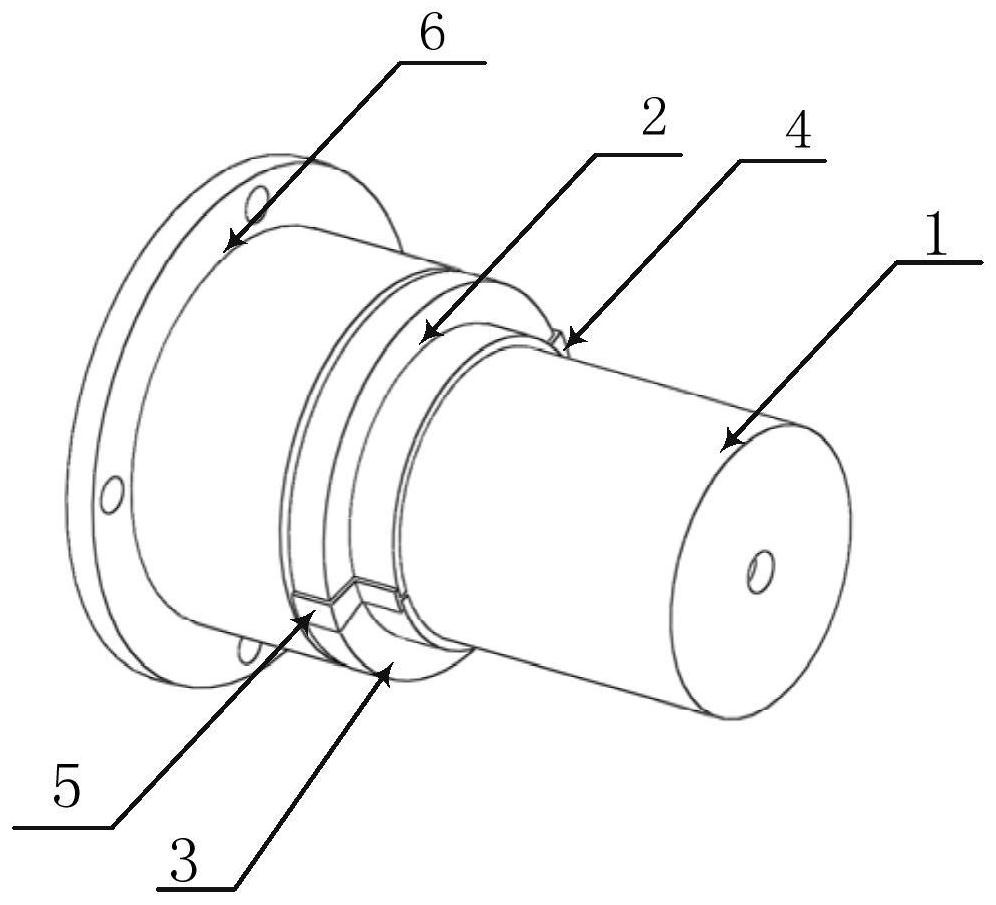

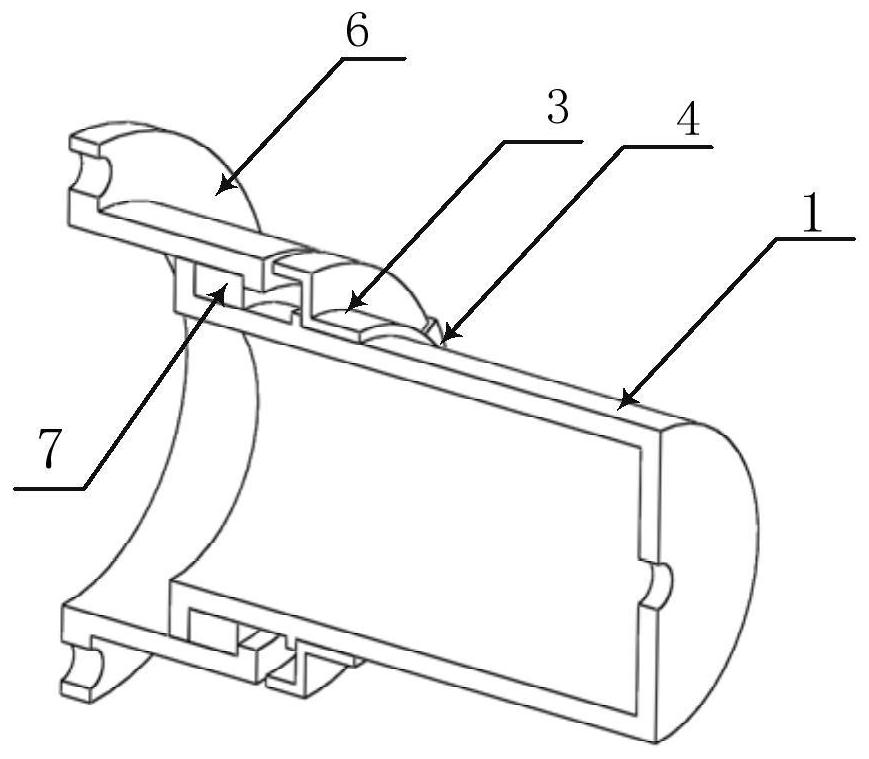

[0051] Fix the mounting flange 6, push the ceramic ring 7 into the mounting flange 6 along the axial direction, so that the two parts fit closely. Then push the contact holding pole shell cylinder 1 into the mounting flange 6 along the axial direction, so that the two parts fit closely. A reliable connection between the mounting flange 6 and the ceramic ring 7 and between the contact holding pole shell cylinder 1 and the ceramic ring 7 is realized by brazing. Push the first half-cylinder 2 and the second half-cylinder 3 in sequence from the second end of the holding pole casing 1 to the first end in the axial direction to the second annular boss position of holding the pole casing 1 , and use spot welding to achieve a stable and reliable connection. The first metal strip 4 and the second metal strip 5 cover the gap in the circumferential direction between the first half cylinder 2 and the second half cylinder 3, and realize stable and reliable connection by spot welding.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com