A low-noise main bearing cap of an internal combustion engine

A main bearing cover, low noise technology, applied to bearings, flexible bearings, crankshaft bearings, etc., can solve the problems of effective control of main bearing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

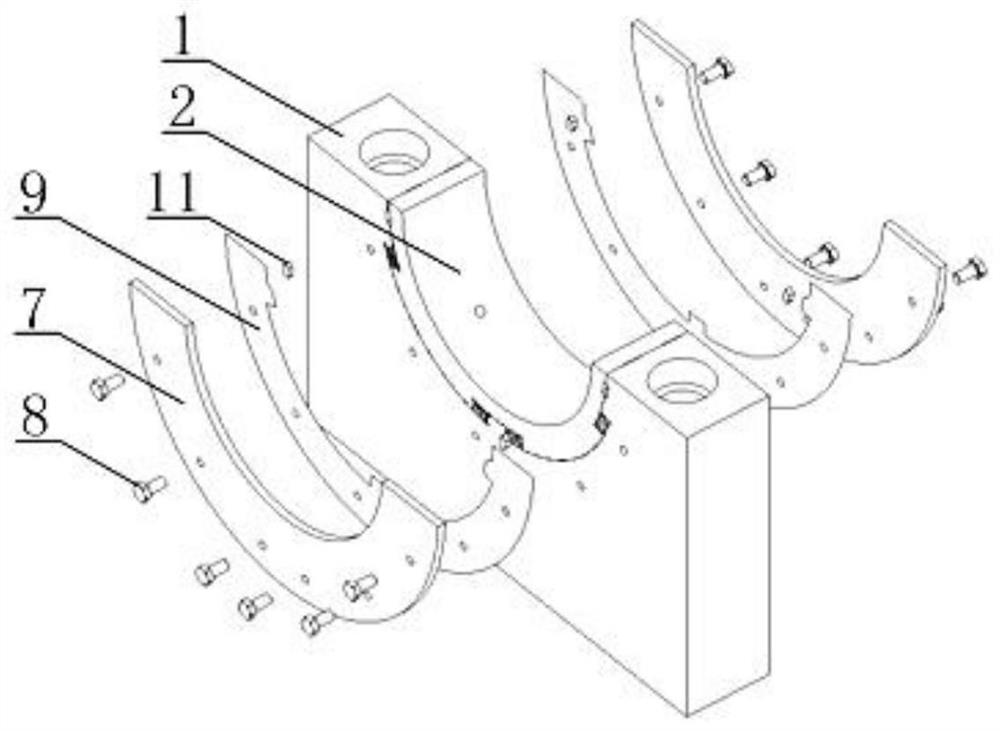

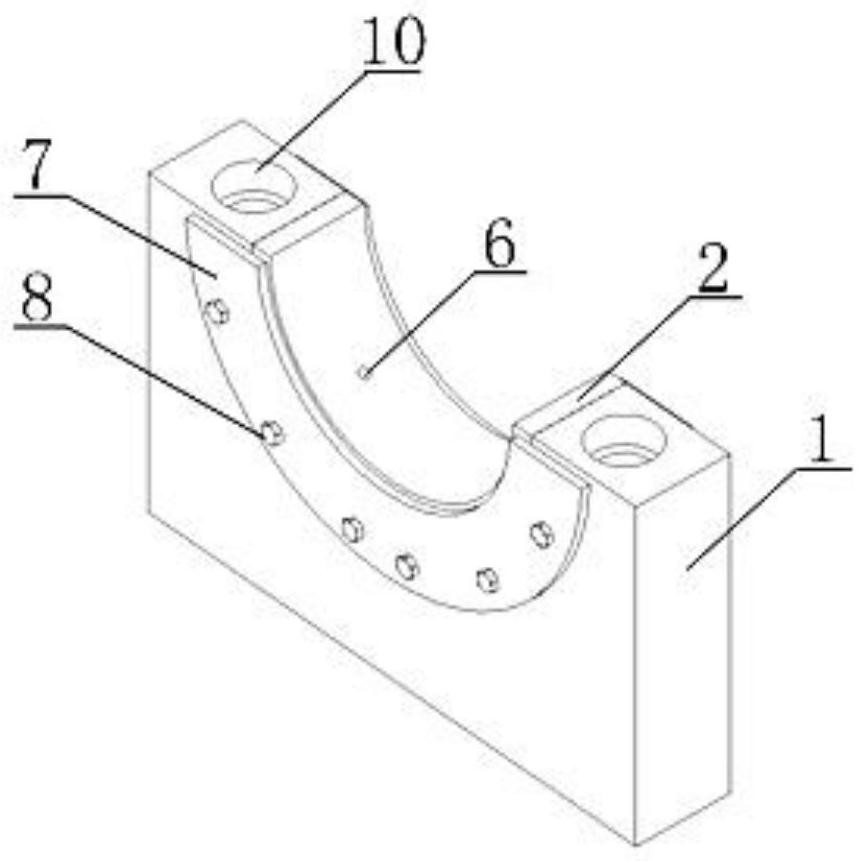

[0031] like Figure 1-4 As shown, this embodiment provides a low-noise main bearing cap of an internal combustion engine, which includes a main bearing cap body 1 connected to the main bearing seat of the machine body, and main bearing bolt holes are provided on both sides of the top of the main bearing cap body 1 10. When in use, the main bearing cap body 1 is fixed on the main bearing seat of the machine body through the main bearing bolts passing through the main bearing bolt holes 10 .

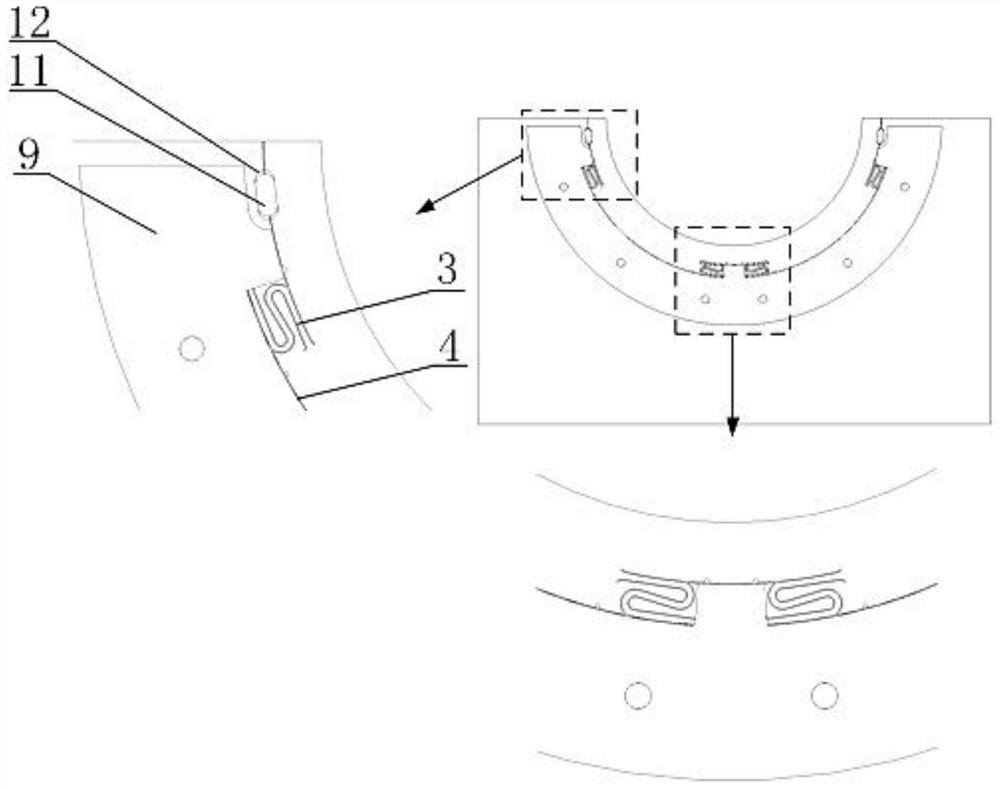

[0032] In this embodiment, a vibration isolator 2 is provided on the main bearing cap body 1 , and a vibration isolation structure is provided between the main bearing cap body 1 and the vibration isolator 2 , and the vibration isolation structure includes an S-shaped structure 3 and an oil film gap 4 . The vibration isolator 2 is provided with an oil inlet passage 6, and the oil inlet passage 6 communicates with the oil film gap 4. During operation, the lubricating oil between the main be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com