Electroplating system and method for BGA area in PCB

A PCB board and area technology, which is applied in the field of electroplating system in the BGA area of the PCB board, can solve the problems of poor uniformity and low signal transmission performance in the PCB board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

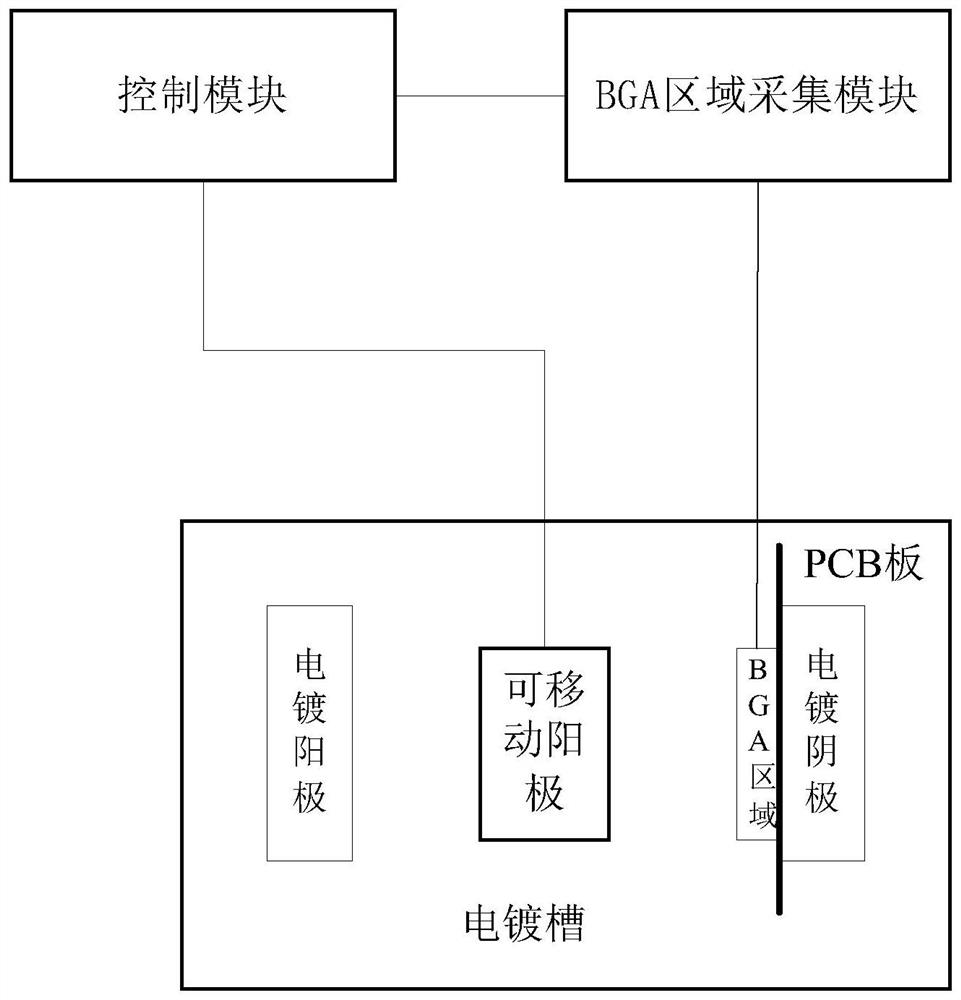

[0041] see figure 1 , figure 1 It is a schematic structural diagram of an electroplating system for a BGA area in a PCB board provided by an embodiment of the present application. Depend on figure 1 It can be seen that the electroplating system in the BGA area of the PCB board in this embodiment mainly includes four parts: an electroplating tank, a BGA area acquisition module, a control module and a movable anode.

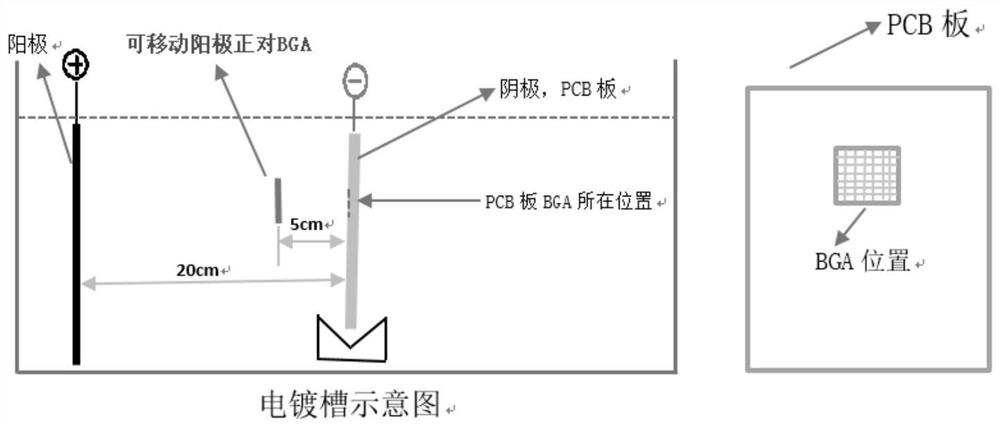

[0042]Among them, the electroplating tank is provided with electroplating anode and electroplating cathode, the electroplating anode is parallel to the electroplating cathode, the PCB board is placed on the electroplating cathode, the movable anode is parallel to the electroplating cathode, and the vertical distance between the movable anode and the electroplating cathode is less than the electroplating cathode. The vertical distance between the anode and the plating cathode. The BGA area acquisition module is used to identify and record the BGA area on the PC...

Embodiment 2

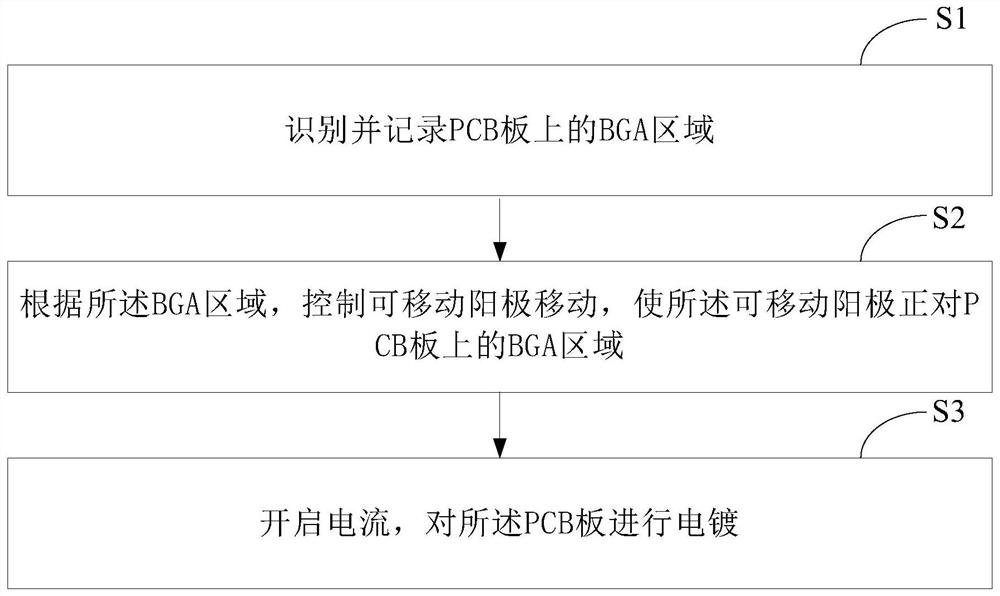

[0052] exist figure 1 and figure 2 On the basis of the illustrated embodiment see image 3 , image 3 It is a schematic flowchart of a method for electroplating a BGA area in a PCB board provided by an embodiment of the present application. Depend on image 3 It can be seen that the electroplating method of the BGA area in the PCB board of this embodiment mainly includes the following processes:

[0053] S1: Identify and record the BGA area on the PCB. Specifically, step S1 includes:

[0054] S11: Collect the arrangement of BGA holes on the PCB, and the BGA holes are used to install the CPU.

[0055] In this embodiment, the camera can be used to capture the layout of the BGA holes on the PCB.

[0056] S12: Identify the BGA area according to the arrangement of the collected BGA holes.

[0057] Specifically, step S12 includes the following processes:

[0058] S121 : According to the arrangement of the collected BGA holes, it is judged whether the number of holes in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com