Glass grinding head motor with brand-new protective structure

A protective structure and glass technology, which is applied in the direction of machine tools, grinders, electromechanical devices, etc., which are suitable for grinding the edge of workpieces, and can solve the problems of slow outflow of mixed liquid, stuck motor, corrosion damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

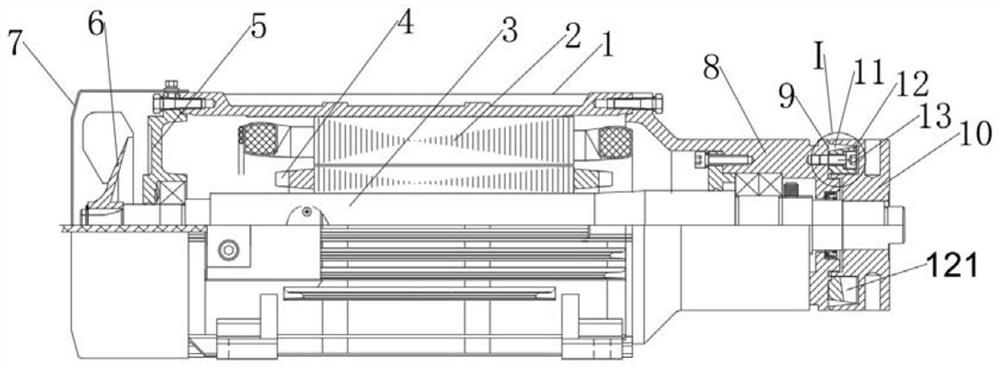

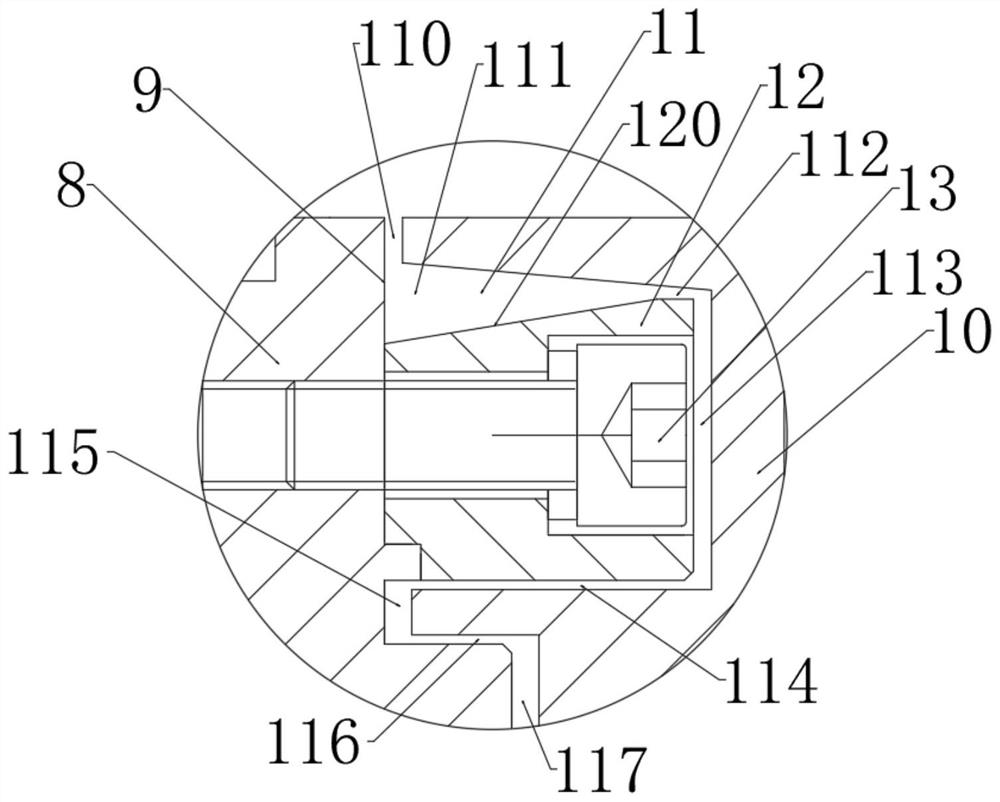

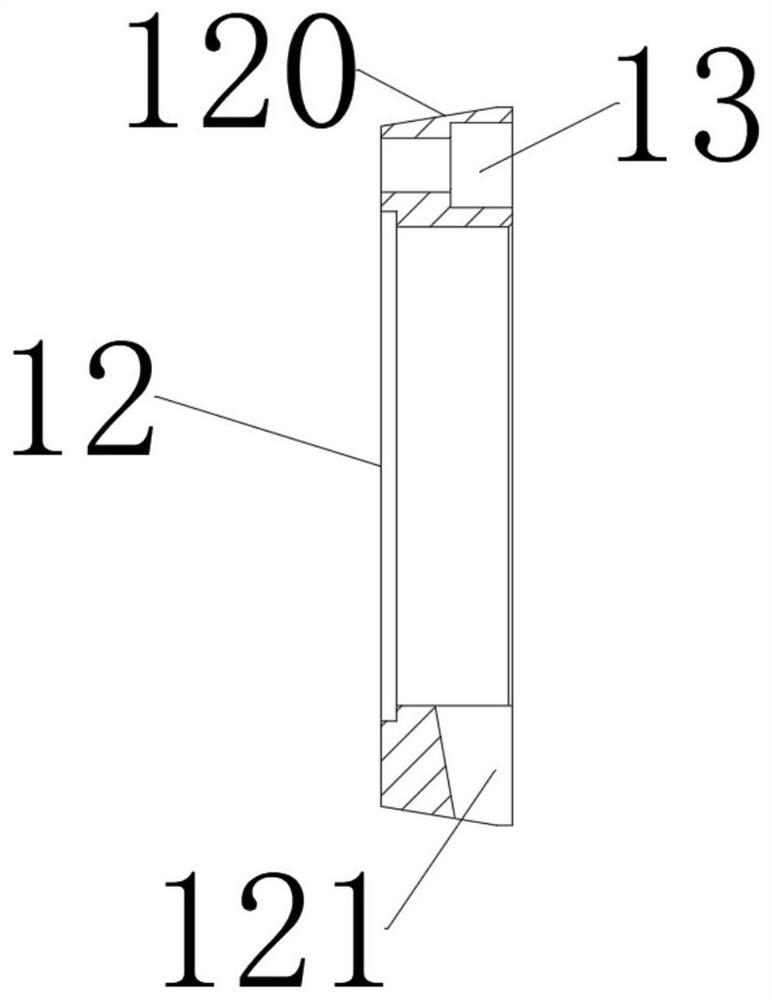

[0012] Depend on Figure 1 to Figure 4 It can be seen that the glass grinding head motor of the present invention mainly includes a housing 1 , a stator core 2 with windings disposed in the housing 1 , and a rotor 4 located in the stator core 2 and supported by the motor shaft 3 . The front and rear ends of the housing 1 are connected with a front end cover 8 and a rear end cover 5, and the front end and the rear end of the motor shaft 3 pass through the front end cover 8 and the rear end cover 5 respectively and are respectively fixed with a grinding wheel seat 10 and a fan. 6. The wind cover 7 covering the fan 6 is also fixed on the rear end cover 5 . The outer edge of the front end face of the front end cover 8 is provided with an end face step 9, and the end face step 9 is fixed with a protective ring 12, and the protective ring 12 is fixed on the end face step 9 by three hexagon socket head cap screws 13. There is a protective gap 11 between the grinding wheel holder 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com