Production process for anti-bonding soft capsule and anti-bonding combined solution for same

A production process and anti-sticking technology, which is applied in the direction of capsule delivery, non-active ingredients of polymer compounds, medical preparations of non-active ingredients, etc., can solve the problems of easy sticking of soft capsules, achieve good protection effect, and solve The effect of bonding into agglomerates and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

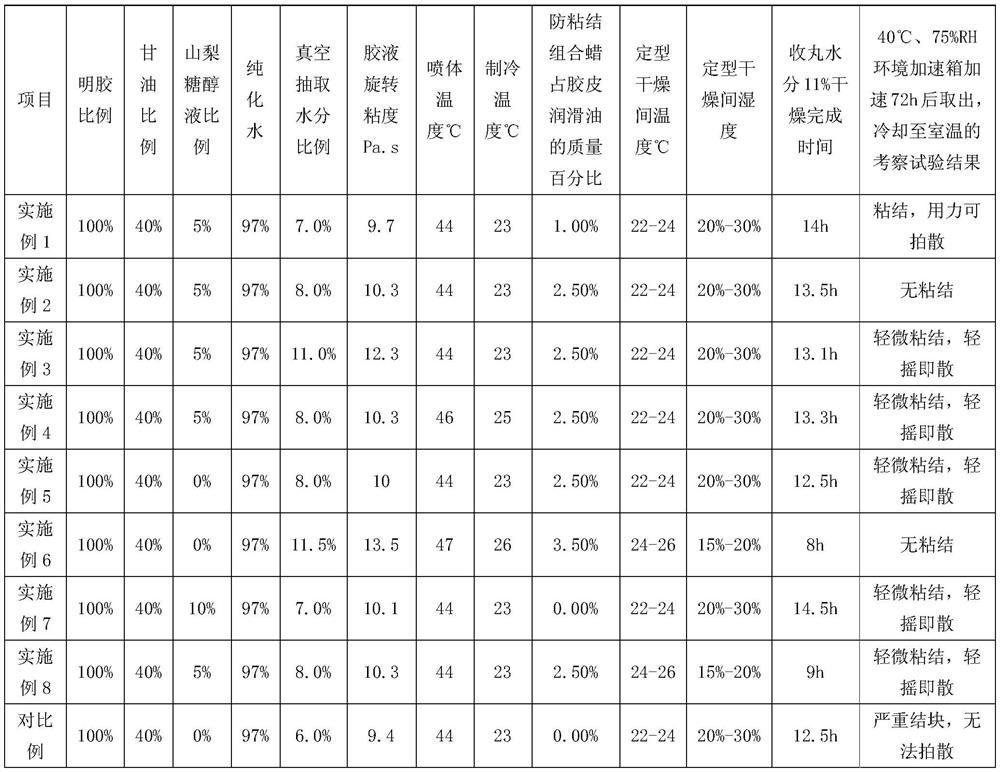

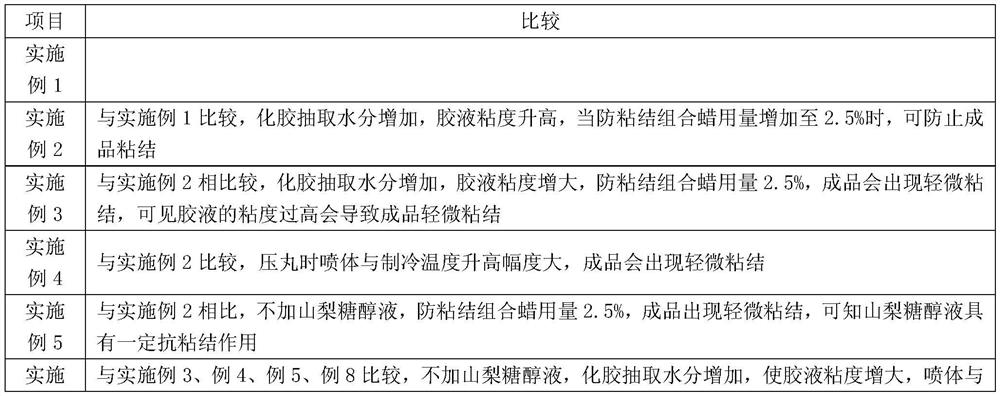

[0053] The embodiment of the present invention provides the specific implementation of soft capsule anti-bonding production technology, and the steps are as follows:

[0054] 1. Prepare 1020g of anti-adhesive combination liquid, which includes 1000g of soft capsule rubber lubricating oil and 20g of anti-adhesive combination wax;

[0055] 2. Put the transparent paraffin oil balls directly into the anti-adhesive combination solution, stir for 10 seconds, take them out, and dry the balls with an oil-absorbing cloth.

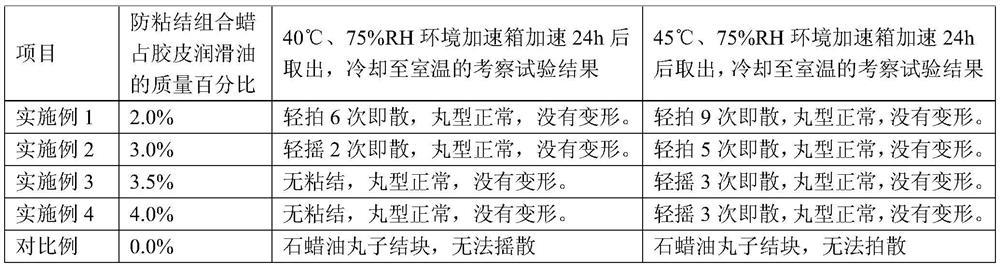

[0056] 3. The paraffin oil balls obtained in Example 1 were carried out to the soft capsule binding test, and the results are shown in Table 1.

Embodiment 2

[0058] The embodiment of the present invention provides the specific implementation of soft capsule anti-bonding production technology, and the steps are as follows:

[0059] 1. Prepare 1030g of anti-adhesive combination liquid, which includes 1000g of soft capsule rubber lubricating oil and 30g of anti-adhesive combination wax;

[0060] 2. Put the transparent paraffin oil balls directly into the anti-adhesive combination solution, stir for 10 seconds, take them out, and dry the balls with an oil-absorbing cloth.

[0061] 3. The paraffin oil balls obtained in Example 2 were subjected to a soft capsule binding test, and the results are shown in Table 1.

Embodiment 3

[0063] The embodiment of the present invention provides the specific implementation of soft capsule anti-bonding production technology, and the steps are as follows:

[0064] 1. Prepare 1035g of anti-adhesive combination liquid, which includes 1000g of soft capsule rubber lubricating oil and 35g of anti-adhesive combination wax;

[0065] 2. Put the transparent paraffin oil balls directly into the anti-adhesive combination solution, stir for 10 seconds, take them out, and dry the balls with an oil-absorbing cloth.

[0066] 3. The paraffin oil balls obtained in Example 3 were subjected to a soft capsule binding test, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com