Steam dust collector

A vacuum cleaner and steam generator technology, applied in vacuum cleaners, cleaning equipment, household appliances, etc., can solve problems such as easy-to-touch shells, high-temperature melting of shells, unreasonable structural layout of steam cleaners, etc., and achieve reasonable structural layout , short path, and the effect of reducing the possibility of high-temperature melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

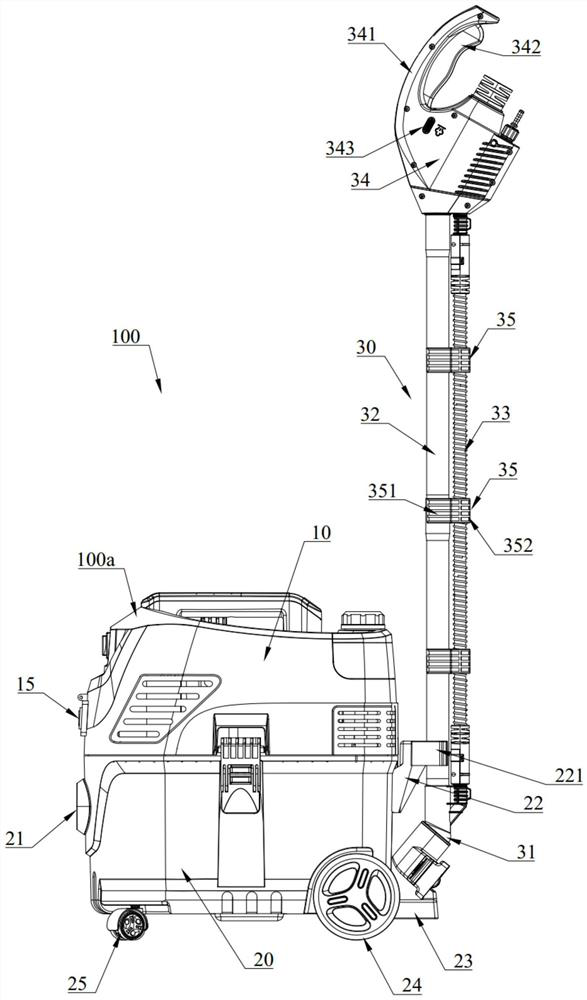

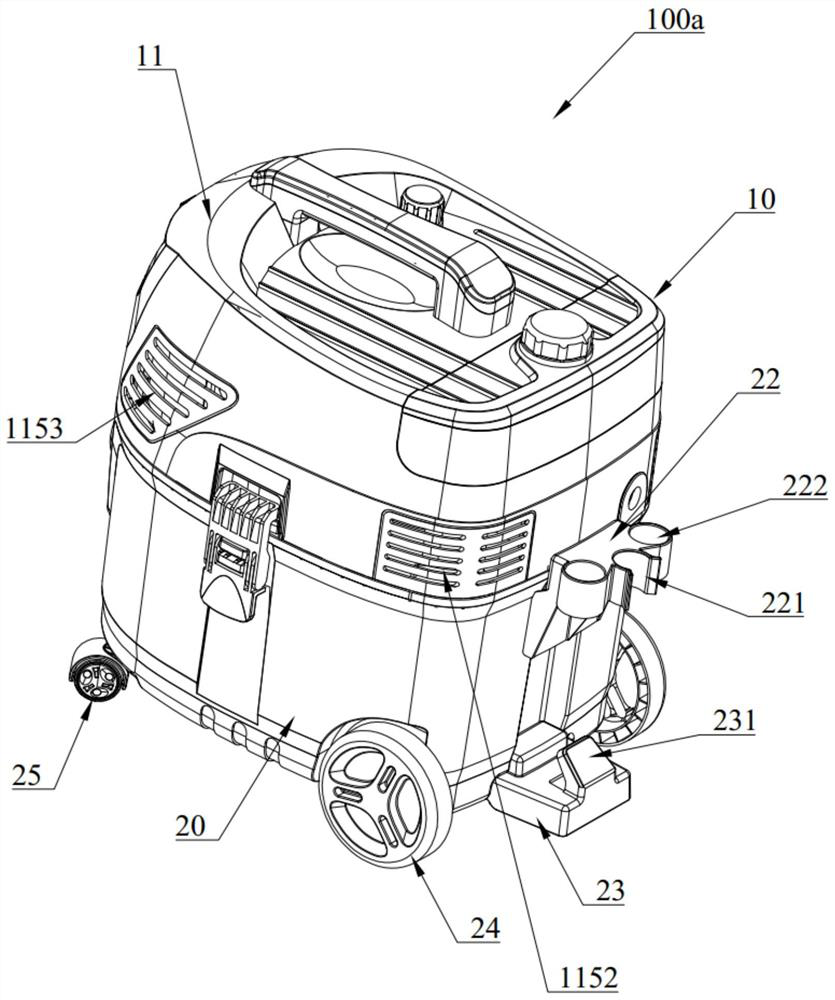

[0035] Such as Figure 1 to Figure 9 As shown, a vacuum cleaner 100 includes: a main body 100 a , working accessories 30 , a dust suction pipeline and a steam pipeline 44 . The dust suction pipeline and the steam pipeline 44 communicate with the main body 100 a and the working accessories 30 . Both the dust suction pipeline and the steam pipeline 44 are hoses, which are convenient for the user to operate the operation attachment 30 for dust suction operation. The main body 100 a includes: a dust box 20 and a box cover 10 . The box cover 10 is mounted to the top of the dust box 20 . The tank cover 10 includes: a tank cover housing 11 , a dust suction fan 12 , a water tank 13 and a steam generator 14 . A dust suction fan 12 , a steam generator 14 and a water tank 13 are installed to the tank cover housing 11 . The vacuum cleaner 100 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com