Charging method of electrochemical device, electronic device and readable storage medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

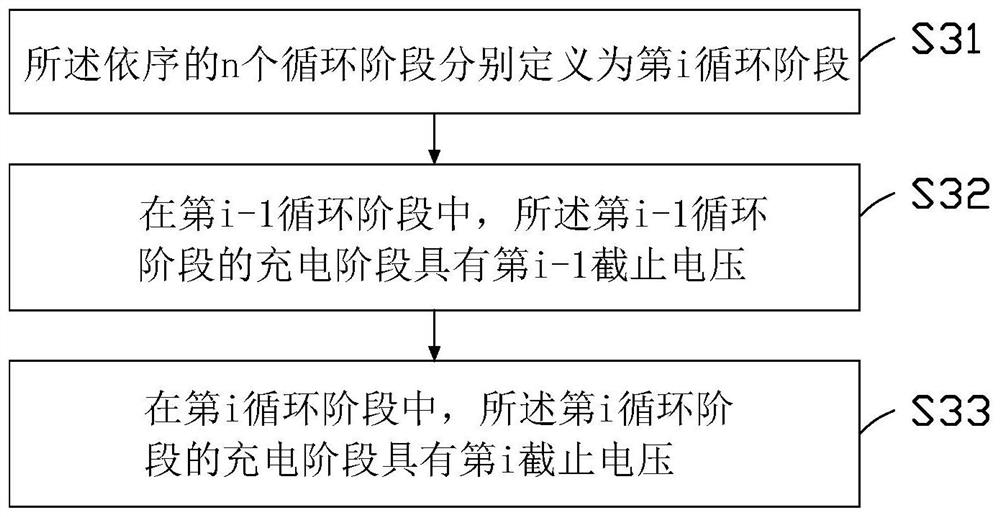

Method used

Image

Examples

Embodiment 1

[0137] Ambient temperature: 25°C; EC / PC content in electrolyte: 20wt%; positive electrode active material: LiNi 0.8 co 0.1 mn 0.1 o 2 ;Particle type: secondary particle; Dv50 / μm of positive electrode active material: 8.5; Electrode assembly structure: winding full tab structure (one tab for each layer of positive pole piece);

[0138] The charging and discharging process in the first cycle stage:

[0139] Step 1, using a constant current of 1.5C to charge the electrochemical device 13 until the voltage of the electrochemical device reaches the cut-off voltage of 4.2V;

[0140] Step 2, using a constant voltage of 4.2V to charge the electrochemical device 13 until the current of the electrochemical device reaches the preset cut-off current (0.05C);

[0141] Step 3, using a preset discharge current to discharge the electrochemical device 13 to a preset discharge cut-off voltage;

[0142] Step 4. Repeat the above step 1 to step 3 300 times, that is, perform 300 charge and dis...

Embodiment 2

[0165] Ambient temperature: 25°C; EC / PC content in electrolyte: 20wt%; positive electrode active material: LiNi 0.8 co 0.1 mn 0.1 o 2 ;Particle type: secondary particle; Dv50 / μm of positive electrode active material: 8.5; Electrode assembly structure: winding full tab structure (one tab for each layer of positive pole piece);

[0166] The charging and discharging process in the first cycle stage:

[0167] Step 1, using a constant current of 1.5C to charge the electrochemical device 13 until the voltage of the electrochemical device reaches the cut-off voltage of 4.2V;

[0168] Step 2, using a constant voltage of 4.2V to charge the electrochemical device 13 until the current of the electrochemical device reaches the preset cut-off current (0.05C);

[0169] Step 3, using a preset discharge current to discharge the electrochemical device 13 to a preset discharge cut-off voltage;

[0170] Step 4. Repeat the above step 1 to step 3 300 times, that is, perform 300 charge and dis...

Embodiment 4

[0200] Embodiment 4 is basically the same as Embodiment 1, except that the third cycle stage of Embodiment 4 includes 200 charge and discharge cycles, and the fifth cycle stage is omitted. The expansion rate of the electrochemical device after 700 cycles in Example 4 was 11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com