Intelligent continuous processing control method and equipment for flexible material

A technology of flexible materials and control methods, applied in the direction of program control, general control system, control/regulation system, etc., can solve the problems of flexible material efficiency and precision reduction, poor document compatibility, discontinuous production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

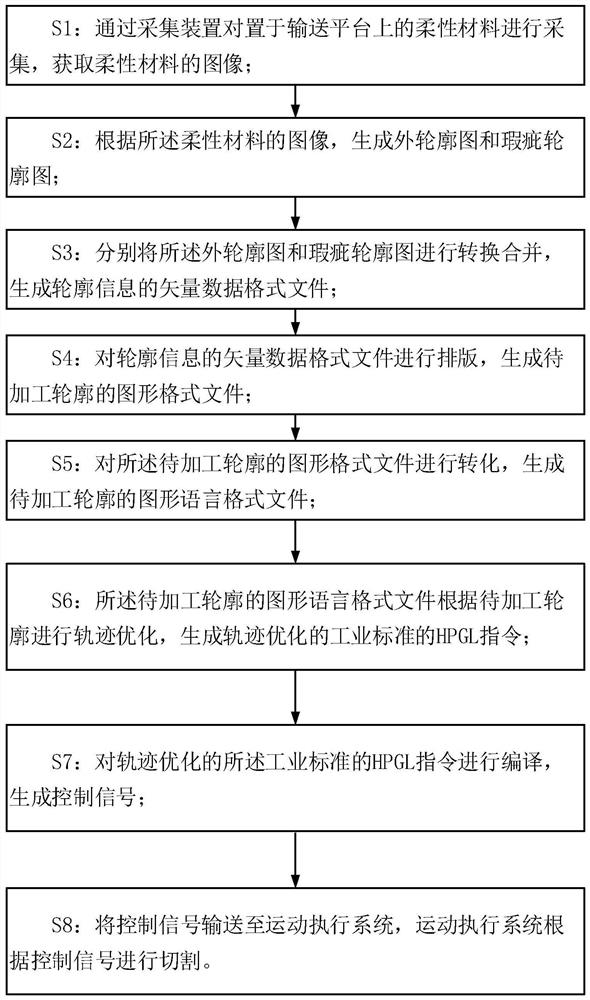

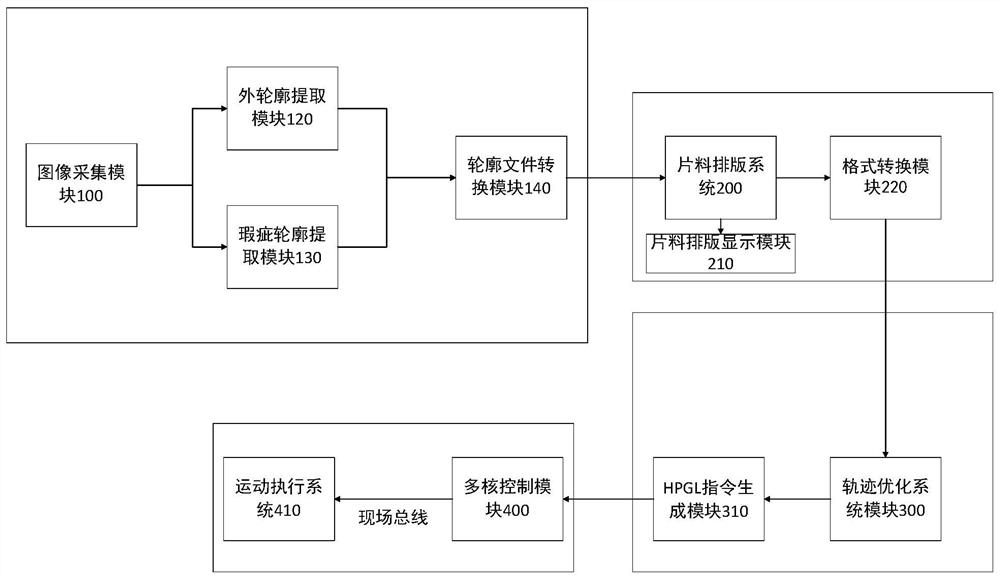

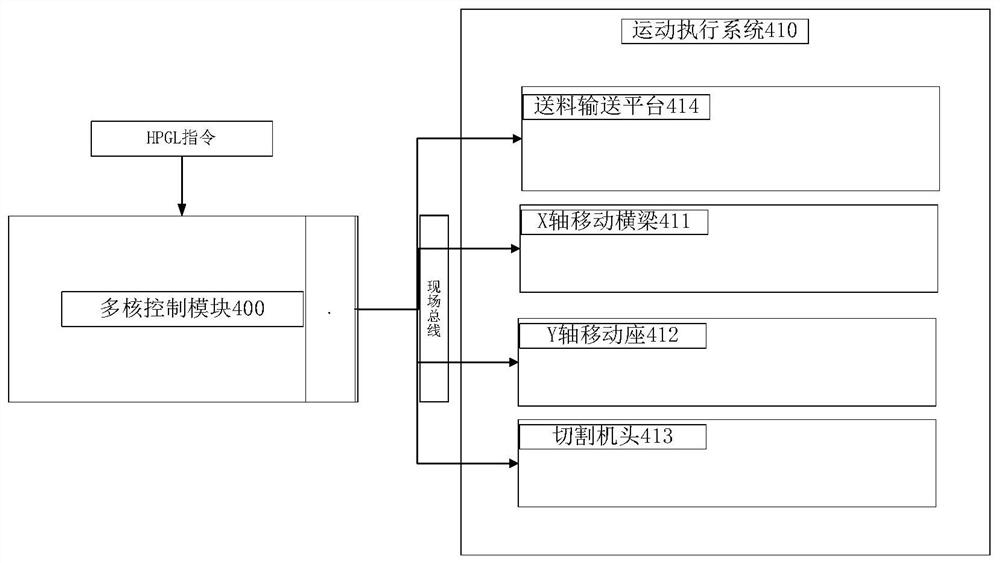

[0047] For ease of understanding, see figure 1 , Embodiment 1 of a flexible material intelligent continuous processing control method provided by this application includes:

[0048] S1: The flexible material placed on the conveying platform is collected by the collecting device, and the image of the flexible material is obtained;

[0049] The collection process in the S1 specifically includes:

[0050] The flexible material is acquired by a line scan camera with a preset scanning range and a preset resolution.

[0051] Wherein, the preset scanning range is 2m×2m, and the preset resolution is 0.06mm / pixel.

[0052] The flexible material is placed on the conveying platform, and moves slowly through the line scan camera. The line scan camera scans and collects the flexible material, and the image information of the flexible material can be obtained. The format of the image of the flexible material is JPG format, PNG format, GIF format. format, BMP format, TIF format and PSD form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com