Method for determining organophosphorus

A technology of organophosphorus and organophosphorus pesticides, which is applied in measuring devices, fluorescence/phosphorescence, instruments, etc., can solve unseen problems and achieve the effects of simple operation, simple modification, and good speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

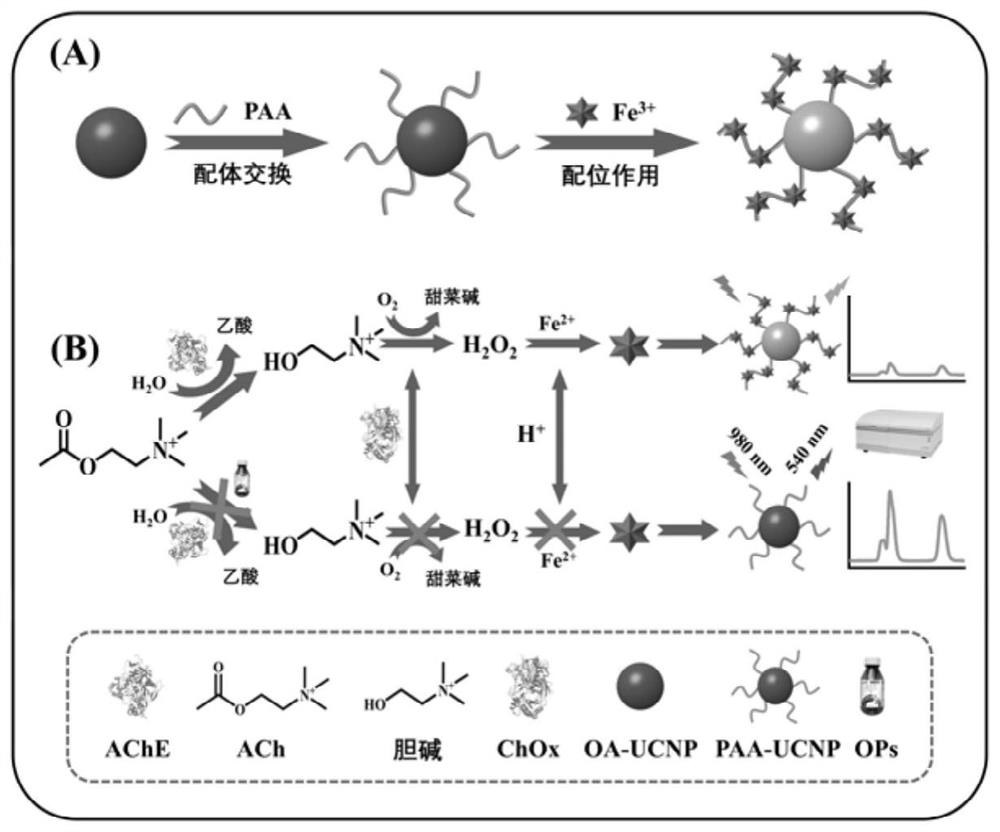

Method used

Image

Examples

Embodiment 1

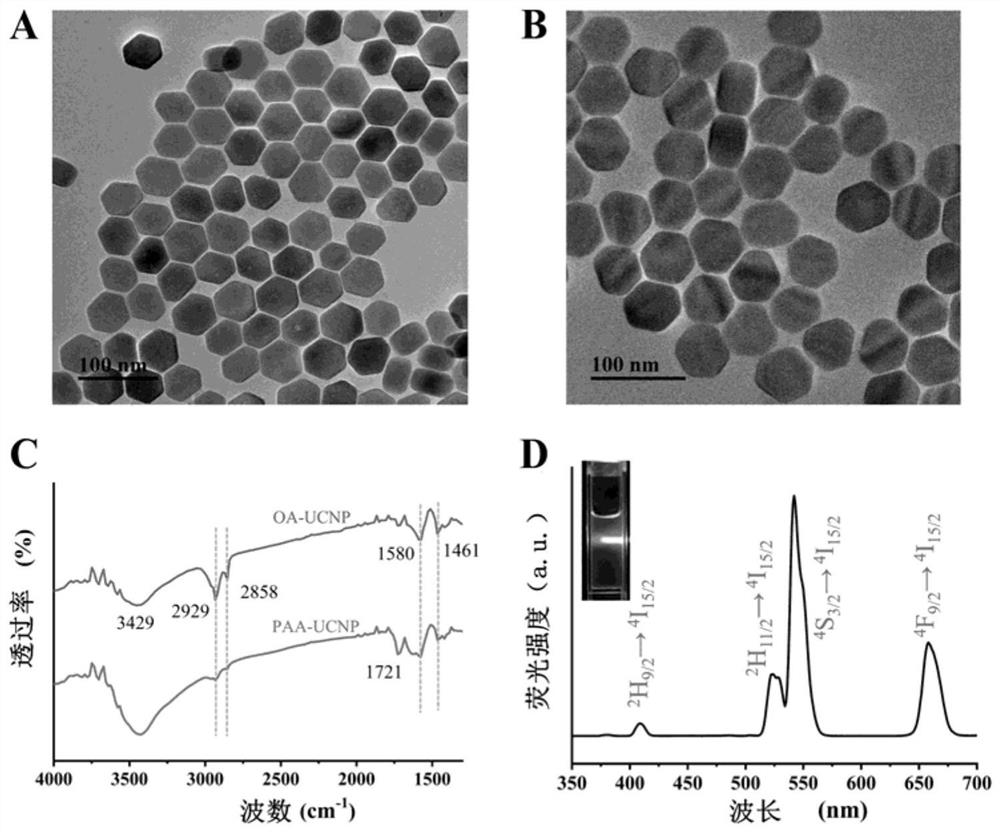

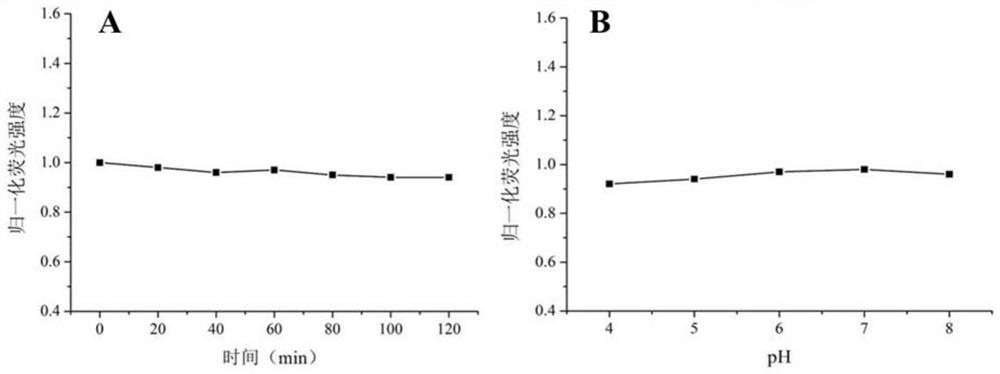

[0038] 1. Preparation of Upconversion Nanomaterials

[0039] (1) NaYF coated with oleic acid 4 : Preparation of Yb, Er up-conversion nanomaterials (OA-UCNPs) The specific method for synthesizing OA-UCNPs by high temperature pyrolysis is as follows: Accurately weigh YbCl 3 ·6H 2 O (0.18mmol), YCl 3 ·6H 2 O (0.8mmol) and ErCl 3 ·7H 2 Add O (0.02mmol) into a 100mL three-necked flask, then add 6mL oleic acid (OA) and 15mL octadecene (1-ODE), and gradually raise the temperature to 160°C under the condition of blowing nitrogen and stirring until the reagents are dissolved evenly Then cool down to room temperature naturally. Weigh 4mmol NH 4 F and 2.5mmol NaOH were dissolved in 10mL of methanol solution, and were added dropwise into a three-necked flask, first heated to 60°C and magnetically stirred for 30min, and then gradually heated to 110°C for evaporation to remove methanol and residual water. Add a condensing reflux device, raise the temperature to 300°C, and continue t...

Embodiment 2

[0054] 1. Preparation of Upconversion Nanomaterials

[0055] (1) NaYF coated with oleic acid 4 : Preparation of Yb, Er up-conversion nanomaterials (OA-UCNPs) The specific method for synthesizing OA-UCNPs by high temperature pyrolysis is as follows: Accurately weigh YbCl 3 ·6H 2 O (0.18mmol), YCl 3 ·6H 2 O (0.80mmol) and ErCl 3 ·7H 2 Add O (0.02mmol) into a 100mL three-neck flask, then add 6mL oleic acid (OA) and 14mL octadecene (1-ODE), and gradually raise the temperature to 150°C under the condition of blowing nitrogen and stirring until the reagents are dissolved evenly Then cool down to room temperature naturally. Weigh 4mmol NH 4 F and 2.5mmol NaOH were dissolved in 10mL of methanol solution and added dropwise to a three-necked flask, first heated to 55°C and magnetically stirred for 45min, then gradually heated to 110°C for evaporation to remove methanol and residual water. Add a condensing reflux device, raise the temperature to 305°C, and continue the reaction f...

Embodiment 3

[0061] 1. Preparation of Upconversion Nanomaterials

[0062] (1) NaYF coated with oleic acid 4 : Preparation of Yb, Er up-conversion nanomaterials (OA-UCNPs) The specific method for synthesizing OA-UCNPs by high temperature pyrolysis is as follows: Accurately weigh YbCl 3 ·6H 2 O (0.18mmol), YCl 3 ·6H 2 O (0.8mmol) and ErCl 3 ·7H 2 Add O (0.02mmol) into a 100mL three-necked flask, then add 6mL oleic acid (OA) and 17mL octadecene (1-ODE), and gradually raise the temperature to 155°C under the condition of blowing nitrogen and stirring until the reagents are dissolved evenly Then cool down to room temperature naturally. Weigh 4mmol NH 4 F and 2.5mmol NaOH were dissolved in 10mL of methanol solution and added dropwise to a three-necked flask, first heated to 50°C and magnetically stirred for 60min, then gradually heated to 110°C for evaporation to remove methanol and residual water. Add a condensing reflux device, raise the temperature to 310°C, and continue the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com