Height control system and method for crucible high-temperature line and growth furnace

A high-level control and high-temperature line technology, applied in the field of growth furnaces, can solve the problems of lack of real-time monitoring data, influence on process parameters, poor accuracy, etc., and achieve the effect of improving process accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

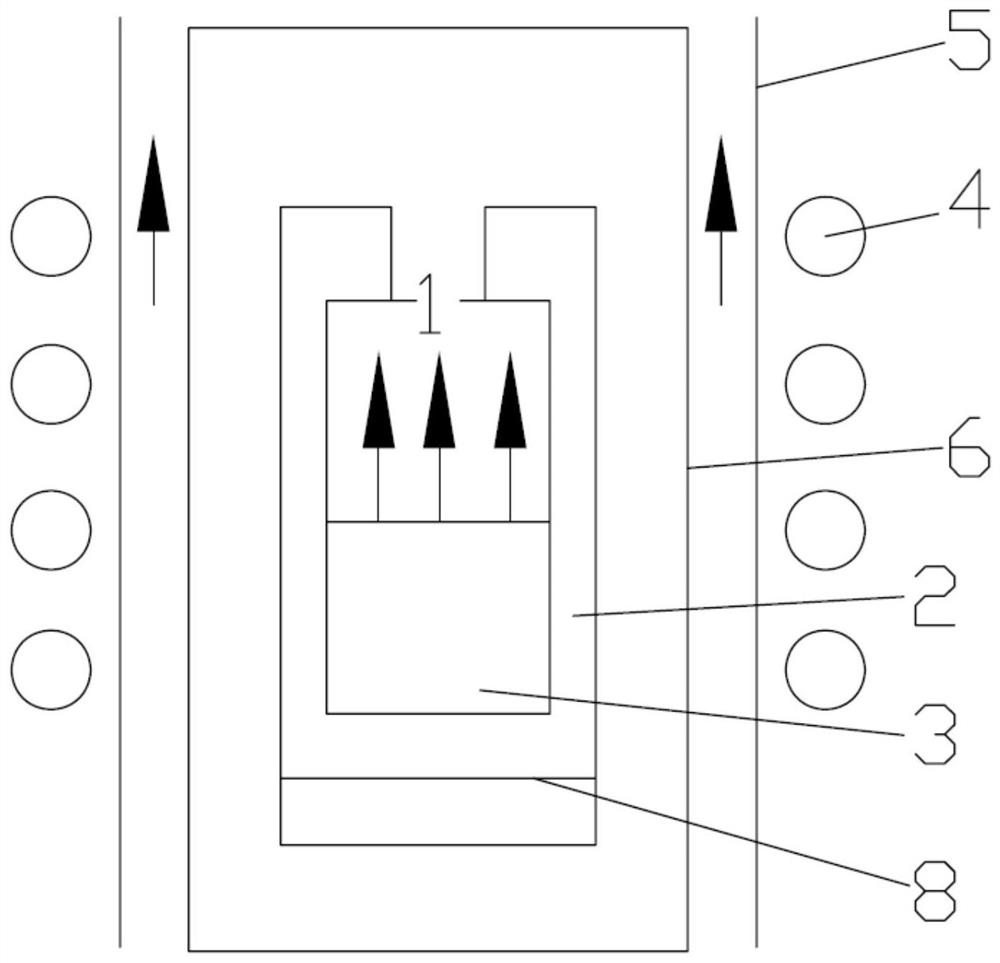

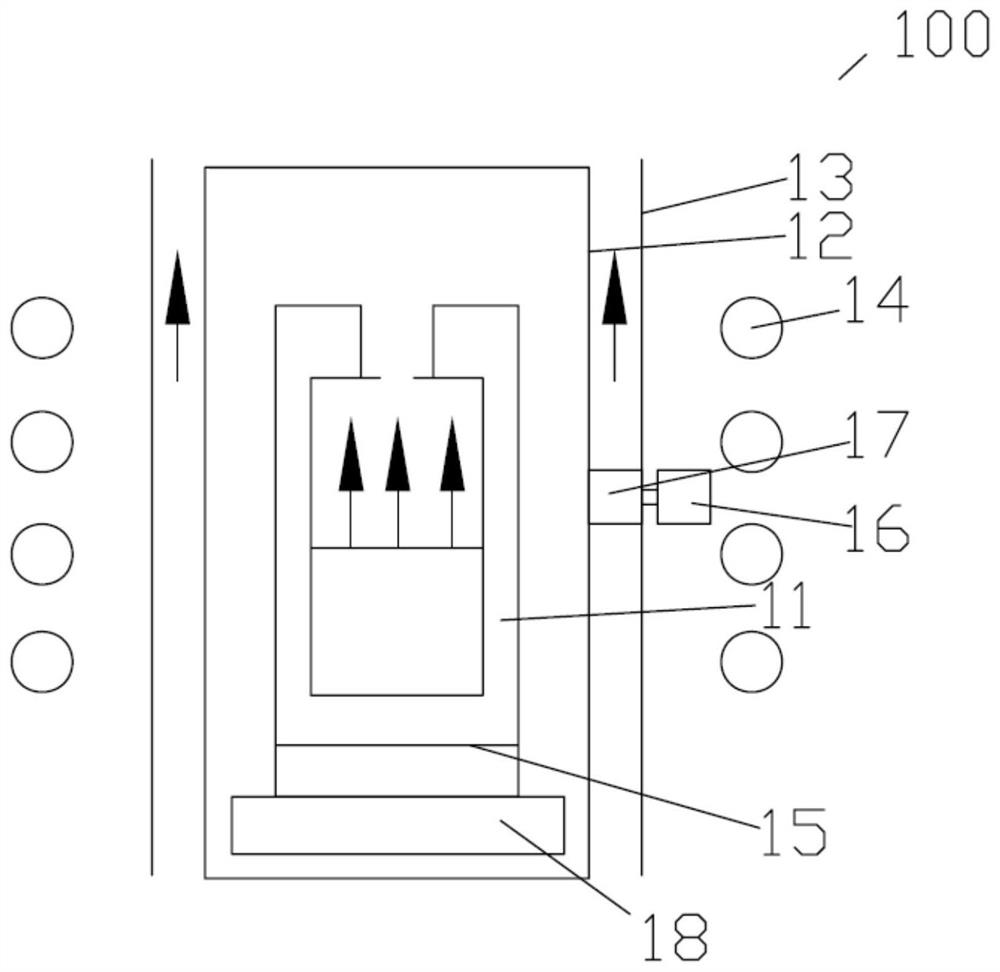

[0038] In order for those skilled in the art to better understand the technical solution of the present invention, the height control system and method of the crucible high-temperature line and the growth furnace provided by the present invention will be described in detail below with reference to the accompanying drawings.

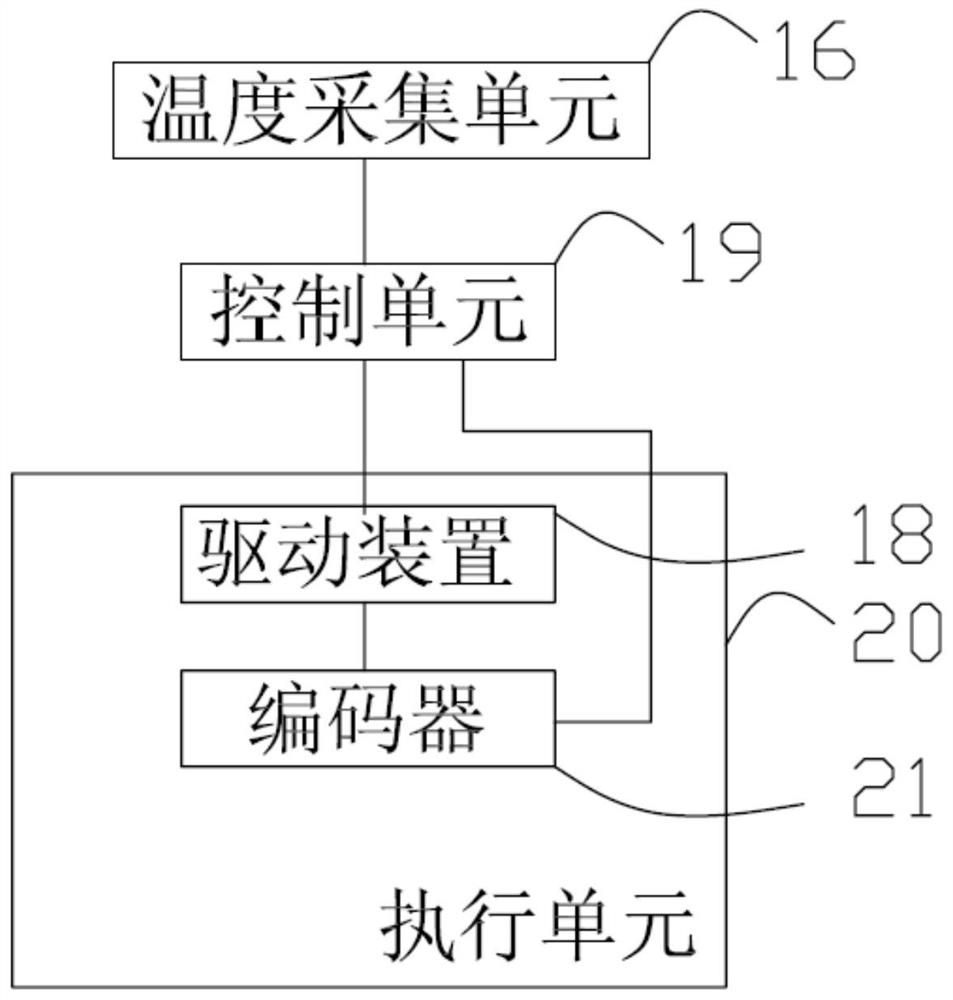

[0039] Please also refer to figure 2 and image 3 , in this embodiment, the growth furnace 100 includes a furnace body, a crucible 11 disposed in the furnace body, an induction coil 14 disposed around the furnace body, and a height control system for the crucible high temperature wire. Wherein, the body of furnace comprises an inner quartz tube 12 and an outer quartz tube 13 which is sheathed at intervals outside the inner quartz tube 12, and the space between the inner quartz tube 12 and the outer quartz tube 13 is filled with cooling water for cooling the quartz tube .

[0040] The height control system of the crucible high-temperature line includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com