Machine tool machine frame for precision instrument machining

A technology of precision instruments and machine tools, used in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of poor shock absorption and machine tool wear, etc., to achieve the effect of easy operation and avoid vibration and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

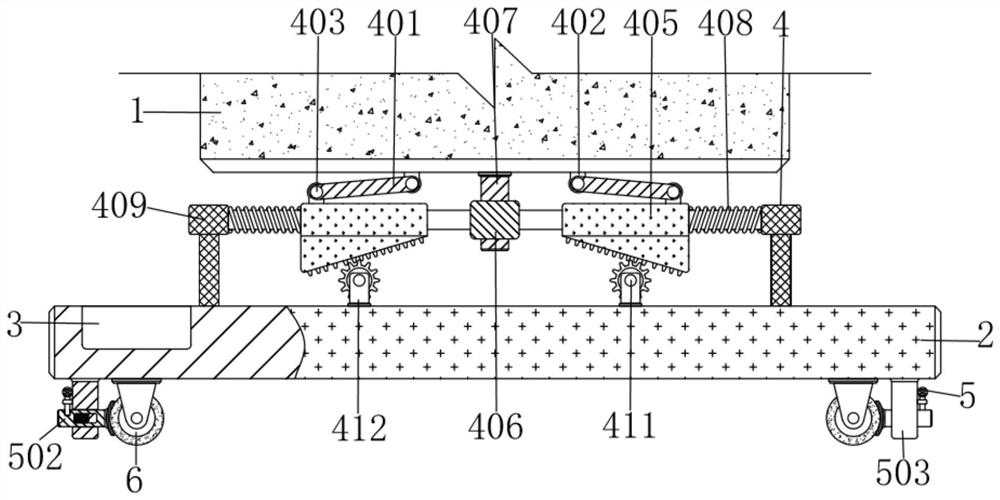

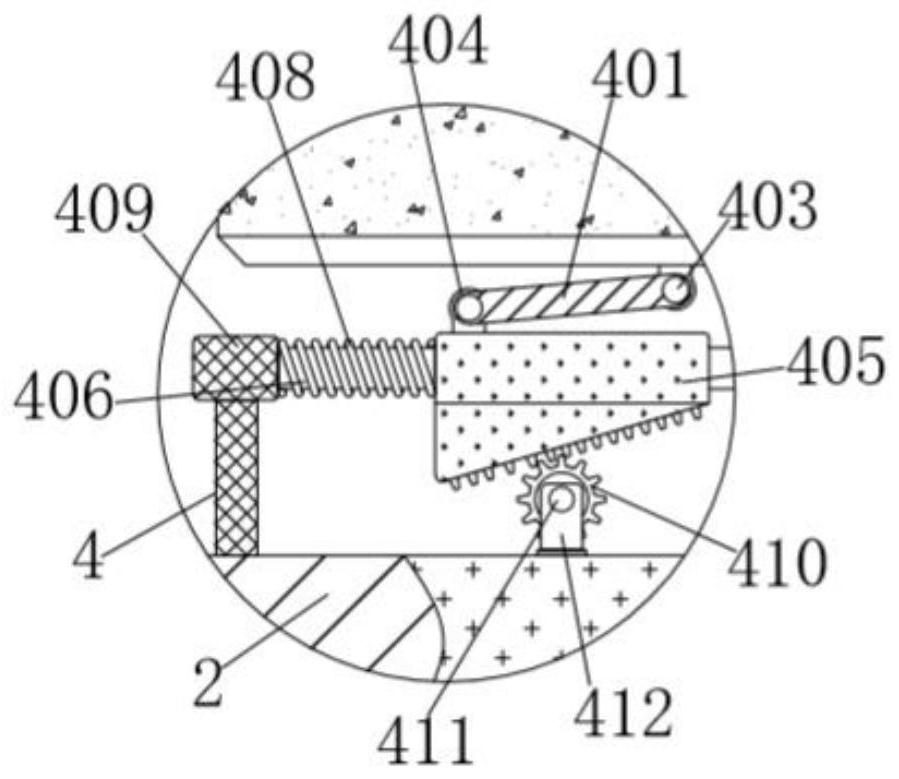

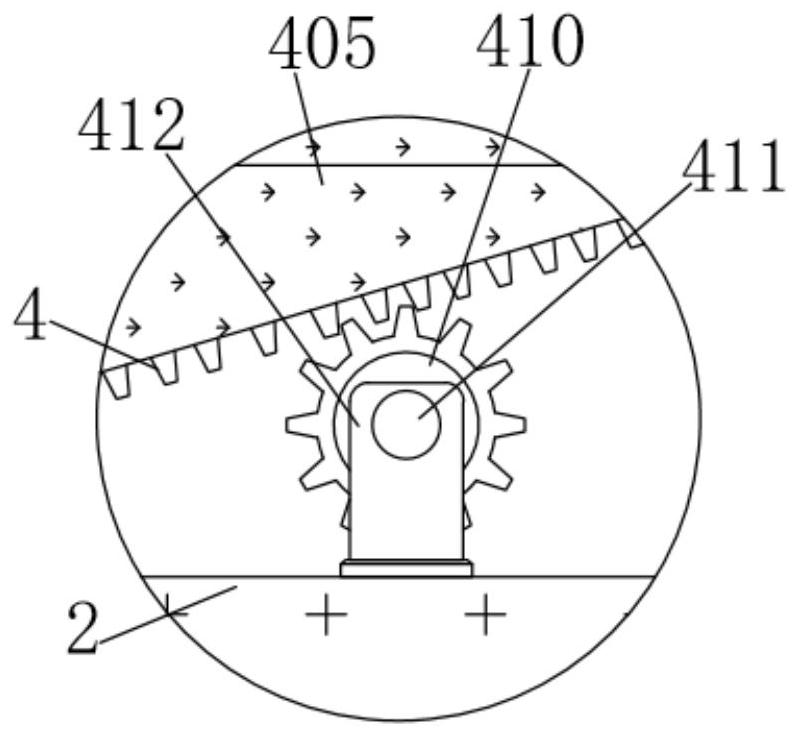

[0032]A machine tool frame for precision instrument processing, comprising a machine tool 1, a frame 2 is installed under the machine tool 1, a buffer mechanism 4 is installed between the machine tool 1 and the frame 2, and the buffer mechanism 4 includes a diagonal bar 401, a first support seat 402, the first pin shaft 403, the second support seat 404, the swash plate 405, the first cross bar 406, the first vertical bar 407, the compression spring 408, the support rod 409, the gear 410, the second pin shaft 411 and the support plate 412 , the right rear end of the left diagonal bar 401 is provided with a first support seat 402, the top of the first support seat 402 is affixed to the left bottom end of the machine tool 1, and the right rear end of the diagonal bar 401 passes through the first pin The shaft 403 is connected to the lower front end of the first support base 402 in rotation, and the oblique bar 401 moves on the first support base 402 through the first pin shaft 403...

Embodiment 2

[0034] As an option, see figure 1 , 5 And 6, the machine tool frame for precision instrument processing, the bottom four corners of the frame 2 are all equipped with a limit mechanism 5, the limit mechanism 5 includes a rubber pad 501, a second cross bar 502, a second vertical bar 503, a chute 504, The slider 505, the card slot 506, the third vertical bar 507 and the third cross bar 508, the outer wall of the right depression of the left front rubber pad 501 is attached to the lower left outer wall of the roller 6, and the rubber pads 501 at the four corners are attached to each other. Fit on the rollers 6 at the four corners to limit the movement of the rollers 6, so that the machine tool 1 on the frame 2 is stable on the ground, the middle of the left end of the rubber pad 501 is fixedly connected with the right end of the second crossbar 502, and the second crossbar 502 The middle outer wall of the second vertical bar 503 is matched with the lower inner wall of the gap, th...

Embodiment 3

[0037] The application of the machine tool frame for precision instrument processing, when using the machine tool frame for precision instrument processing, firstly, the frame 2 can move the position of the machine tool 1 on the frame 2 through the rollers 6 at the four corners, and the machine tool 1 passes through the position during transportation. The inclined bars 401 on both sides drive the inclined plates 405 on both sides to move outward on the outer walls of both sides of the first cross bar 406 to compress the compression springs 408 on both sides, otherwise the elasticity of the compression springs 408 on both sides can offset the impact of the machine tool 1 The external force exerts a buffering effect on the machine tool 1 to avoid vibration and wear of the equipment on the machine tool 1. The chute 504 in the second crossbar 502 at the four corners is on the slider 505 in the through groove on the second vertical bar 503 to the inside Sliding can make the rubber p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com