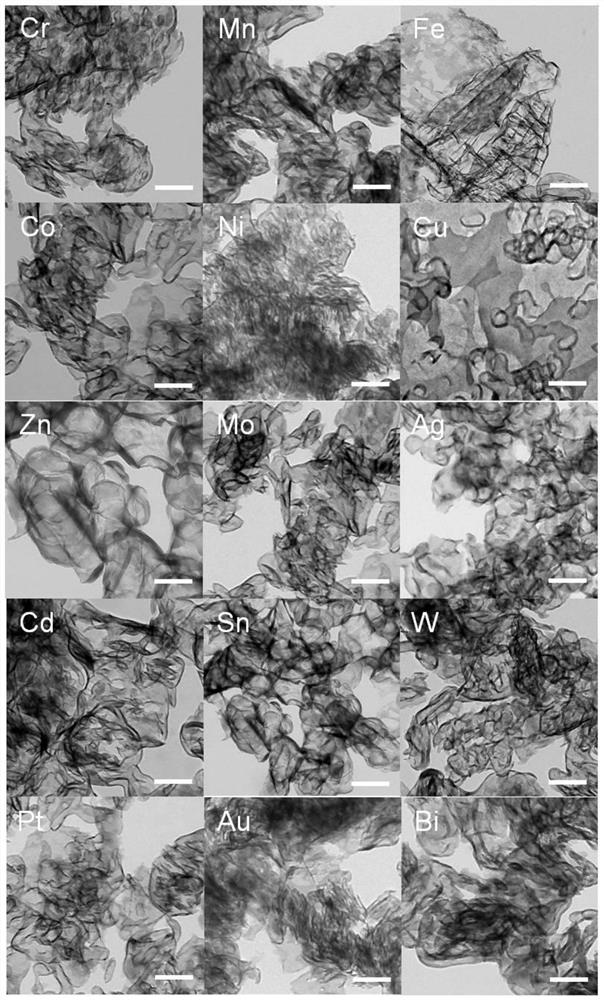

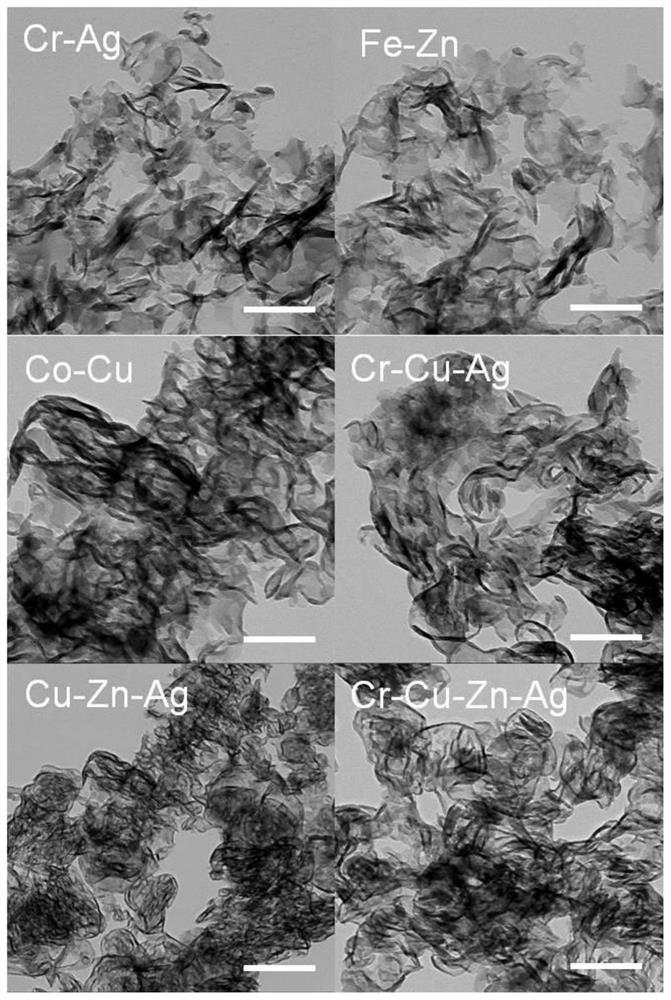

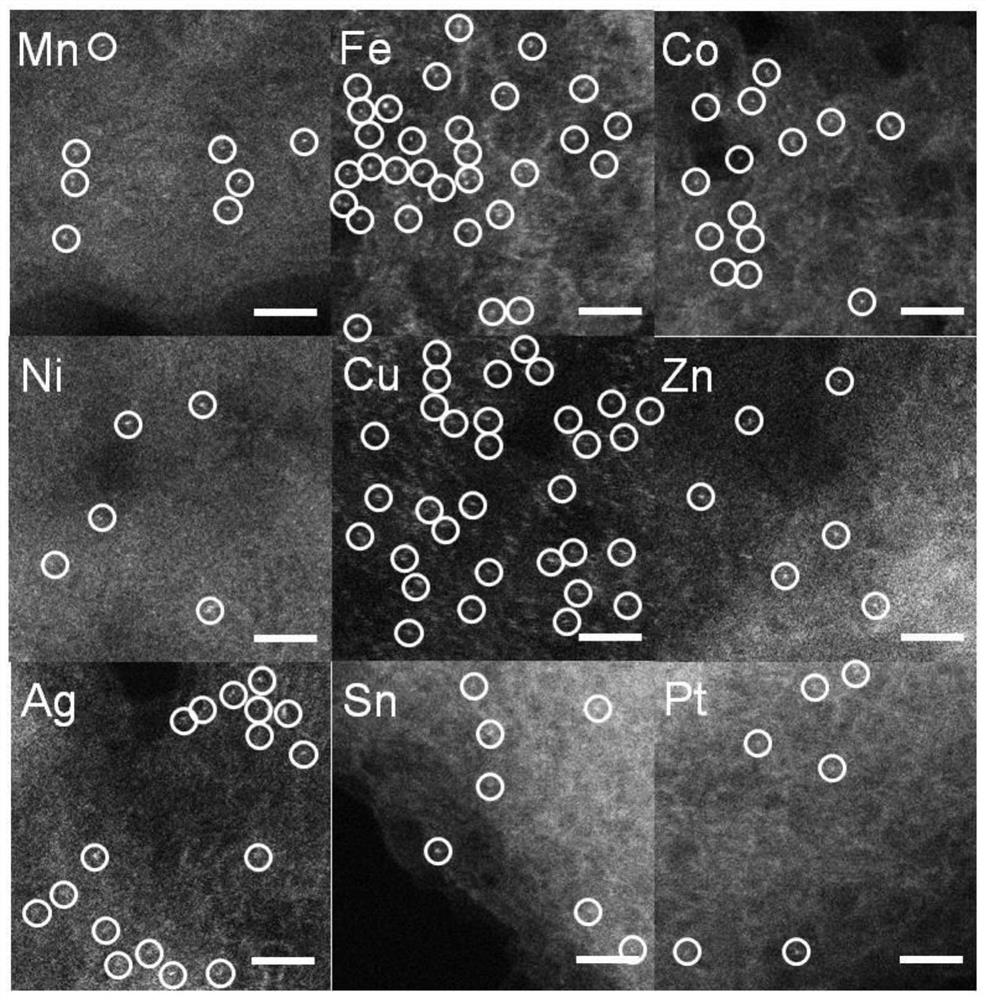

Controllable synthesis method of monoatomic catalyst with low cost and high loading capacity

A high-load, synthetic method technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen/synthesis gas production, etc., can solve the problems of easy metal agglomeration, low single-atom loading, etc. High, excellent catalytic stability, high metal atom loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0025] 1) Synthesis of chromium (Cr) single atom catalyst:

[0026] (1) Take by weighing 1-4 grams of melamine and cyanuric acid respectively, add 100-500 milliliters of water to dissolve respectively, obtain solution A and solution B;

[0027] (2) Weigh 50-1000 mg of citric acid and 60-900 mg of chromium nitrate, add to 20-100 ml of water and dissolve to obtain solution C;

[0028] (3) Mix solution B and solution C and stir evenly to obtain solution D;

[0029] (4) Mix solution A and solution D to form a precipitate, and obtain the precursor after centrifugation, washing 3 times with water, washing 1 time with ethanol, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com