A kind of ethanol preparation and purification system

A technology of ethanol and ethanol reflux, which is applied in the preparation of hydroxyl compounds, organic compounds, distillation adjustment/control, etc., can solve the problems of insufficient ethanol concentration and poor separation effect, and achieve convenient separation, energy saving, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

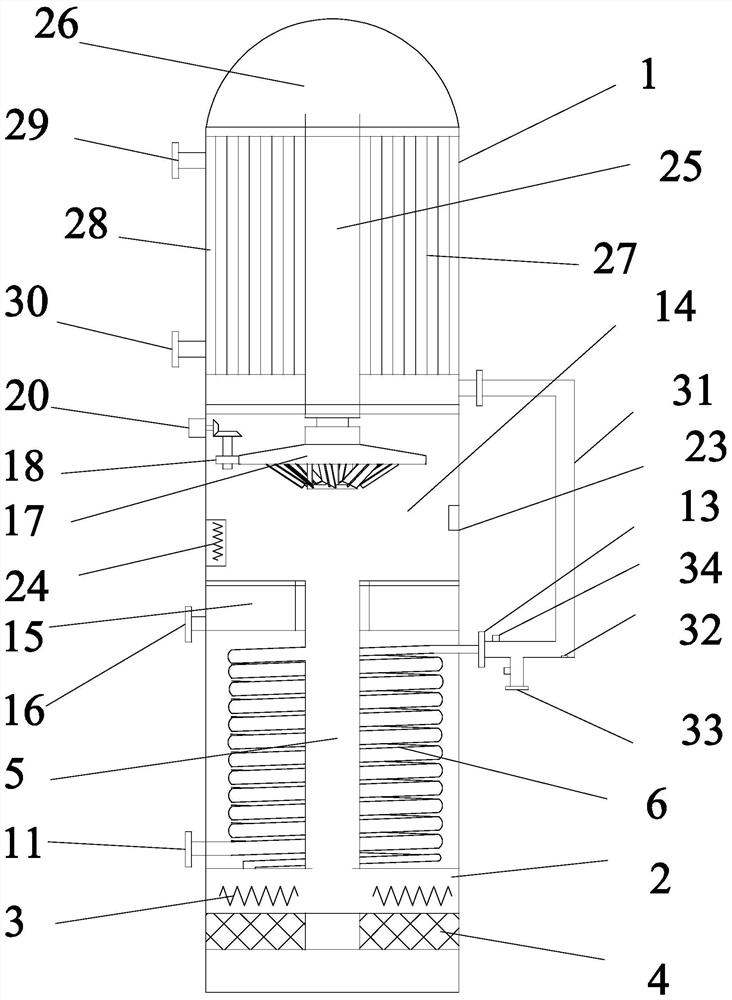

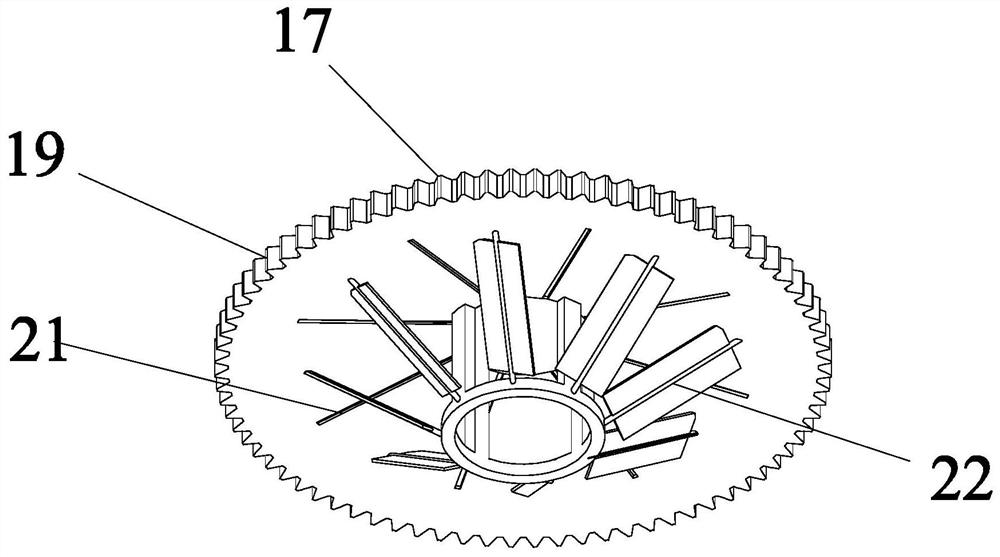

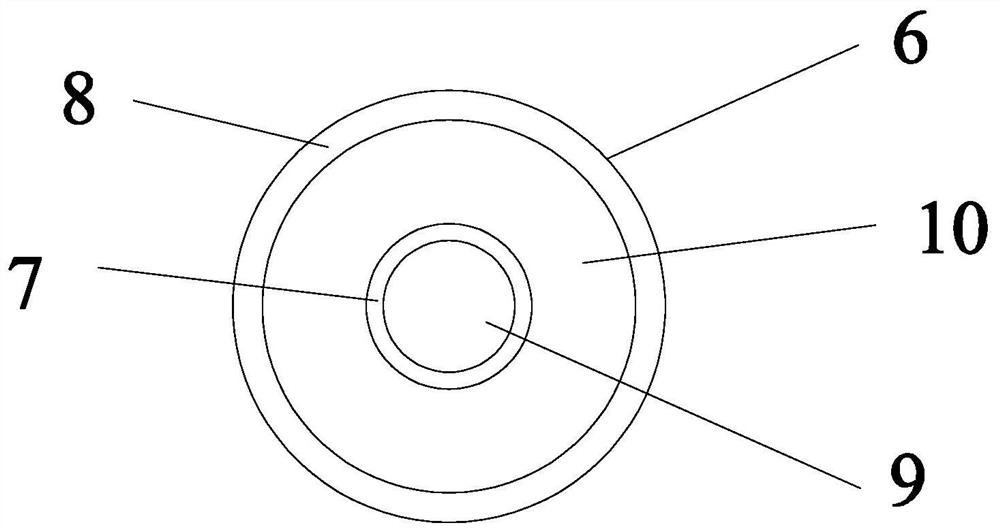

[0023] Embodiment one, such as Figure 1-3 Shown, a kind of ethanol preparation purification system comprises distillation column 1, and the bottom of described distillation column is provided with secondary azeotropic chamber 2, and described secondary azeotropic chamber is provided with heating wire 3, and described secondary azeotropic chamber The bottom of the bottom is provided with filler 4, and the top of described secondary azeotropic chamber is connected with water condensation passage 5, and described water condensation passage is the passage in vertical direction in the middle of distillation tower; Composite passage 6, the composite passage includes an inner layer pipe 7 and an outer layer pipe 8 sleeved outside the inner layer pipe, the inner layer pipe is the ethanol return channel 9, and the outer layer pipe and the inner layer The part between the pipelines is an azeotropic gas channel 10, the lower end of which is connected to the feed port 11 for adding the a...

Embodiment 2

[0025] Embodiment two: if Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the composite channel includes a first cavity 36 and a second cavity 37 separated by a partition 35, and the first cavity is the ethanol return channel , the second cavity is the azeotropic gas channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com