Motor rotor paint dipping device and using method thereof

A technology of motor rotor and dipping paint, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of poor dipping effect, low efficiency and narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

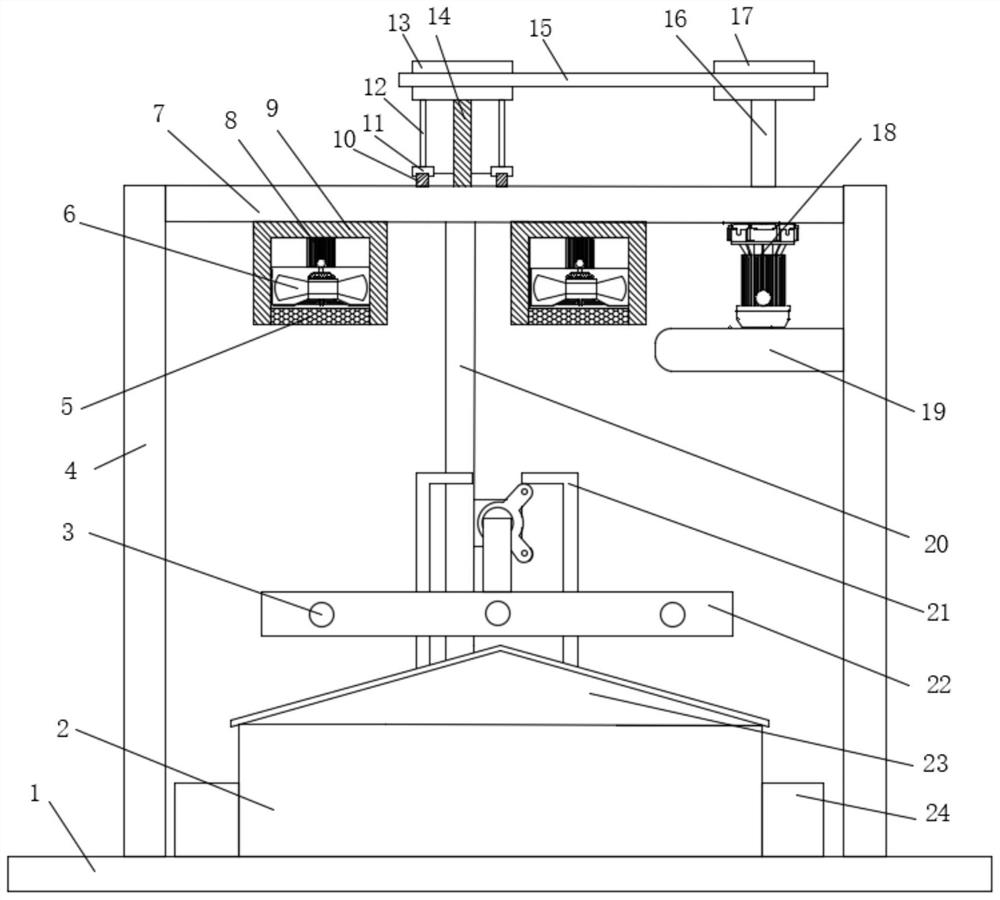

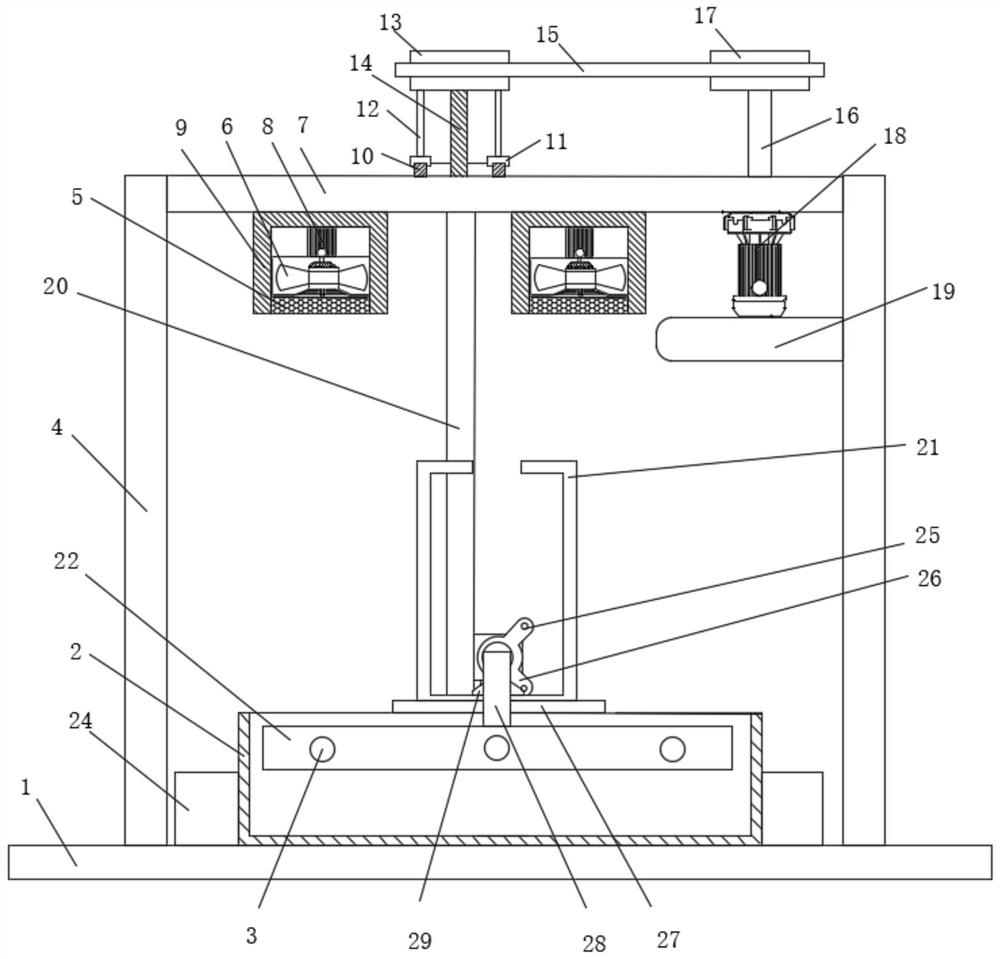

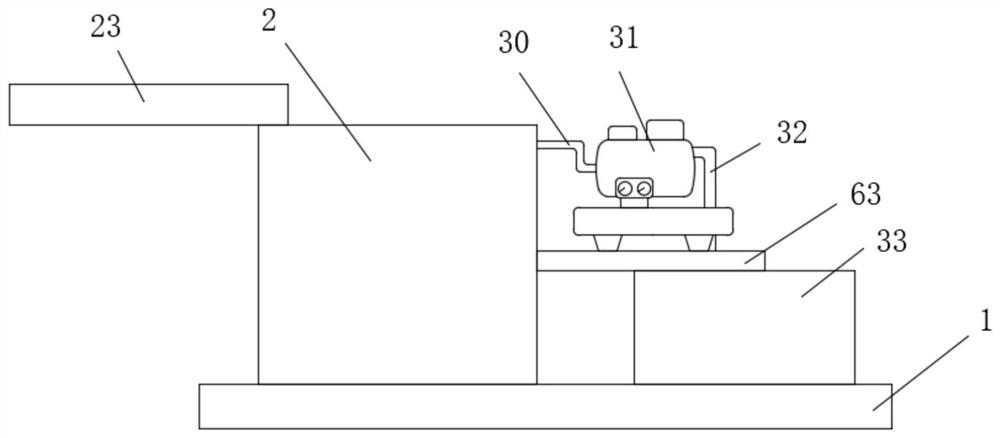

[0051] Embodiment one: if Figure 1-15 As shown, a motor rotor impregnating device includes a fixed base 1 and a motor rotor body 46, the top of the fixed base 1 is fixedly connected with two symmetrically arranged support columns 4, and the top of the side of the two support columns 4 close to each other is fixed The same first mounting plate 7 is connected, and the bottom of the first mounting plate 7 has an air-drying assembly for air-drying the rotor body 46 of the motor. The top of the fixed base 1 is fixedly connected with a paint dipping box 2, and one side of the paint dipping box 2 is placed separately. There is a steering assembly for turning over the motor rotor body 46 and a paint touch-up assembly for replenishing the paint dipping box 2. The top of the first mounting plate 7 is provided with a lifting assembly for lifting the motor rotor body 46. One side of the lifting assembly A placement assembly for placing the motor rotor body 46 is fixedly connected.

[00...

Embodiment 2

[0069] Embodiment two: if Figure 16 As shown, a motor rotor impregnating device, the difference between this embodiment and Embodiment 1 is: the top of the fixed base 1 is fixedly connected with a sealing cover 58, and one side of the sealing cover 58 is provided with a transparent window 62 and a door opening. A door 57 is hinged inside, a sealing ring 61 is arranged between the door 57 and the inlet and outlet, a handle 59 is arranged on one side of the door 57, a vacuum pump 60 is arranged on the top of the fixed base 1, and the vacuum pump 60 communicates with the sealing cover 58, and the support column 4. The first mounting plate 7 and the paint dipping box 2 are all located in the sealing cover 58. During the paint dipping operation, the vacuum pump 60 can be started, so that the inside of the sealing cover 58 is in a vacuum state, so that the motor rotor body 46 can be better dipped in paint. After the dipping operation is completed, close the vacuum pump 60, open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com