Installation structure of cable bridge

A technology of installation structure and cable tray, which is applied in the direction of electrical components, etc., can solve the problems of high production cost, heavy cable tray weight, easy shaking of cable tray, etc., and achieve the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Attached to the following Figure 1-6 This application will be described in further detail.

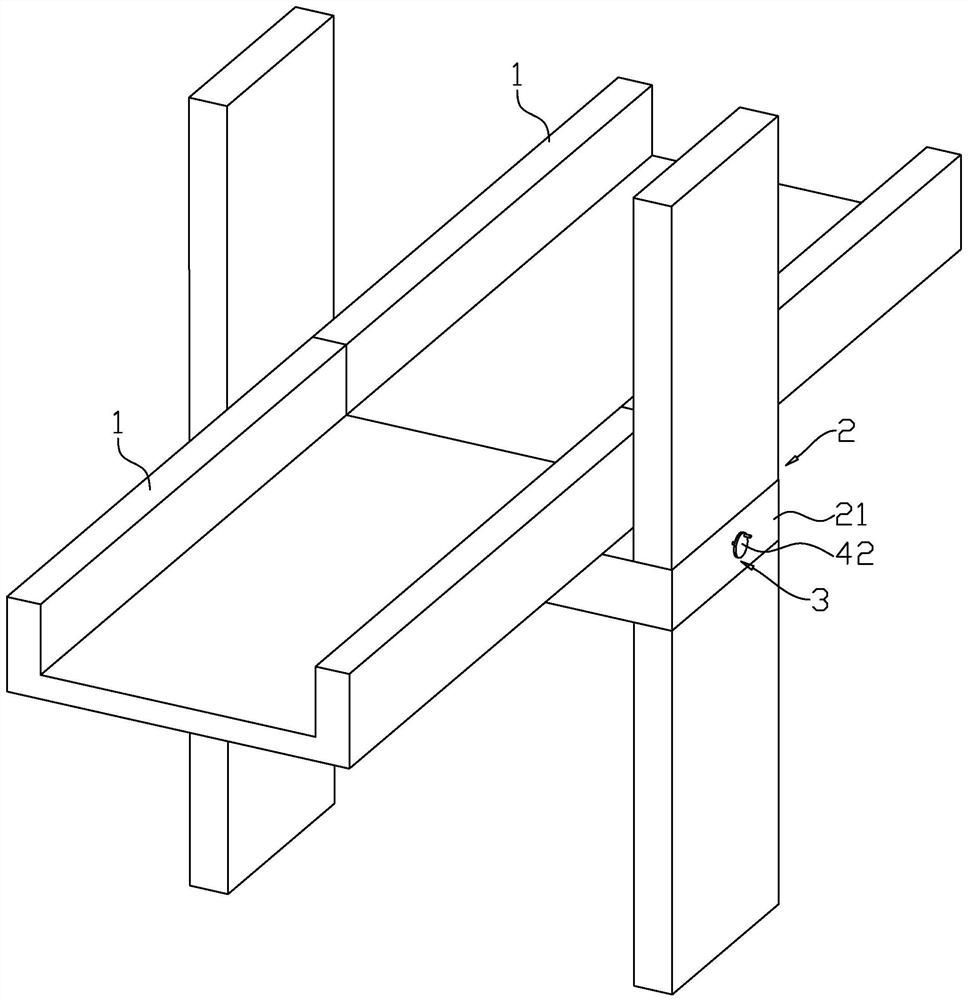

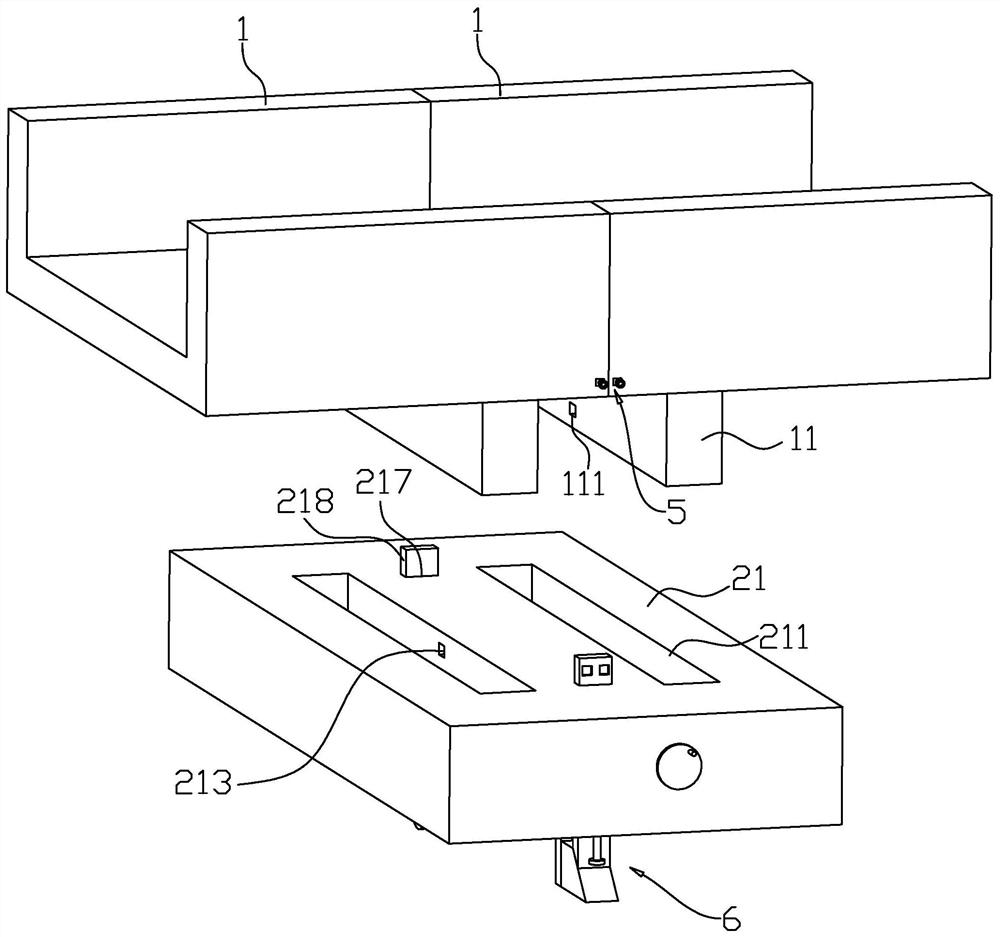

[0037] The embodiment of the present application discloses an installation structure of a cable tray, such as figure 1 As shown, it includes a plurality of bridge bodies 1, and a mounting frame 2 is installed between two adjacent bridge bodies 1. The two ends of the mounting frame 2 are respectively fixed to the ground and the top of the wall through expansion bolts, and the mounting frame 2 includes a horizontal plate 21 .

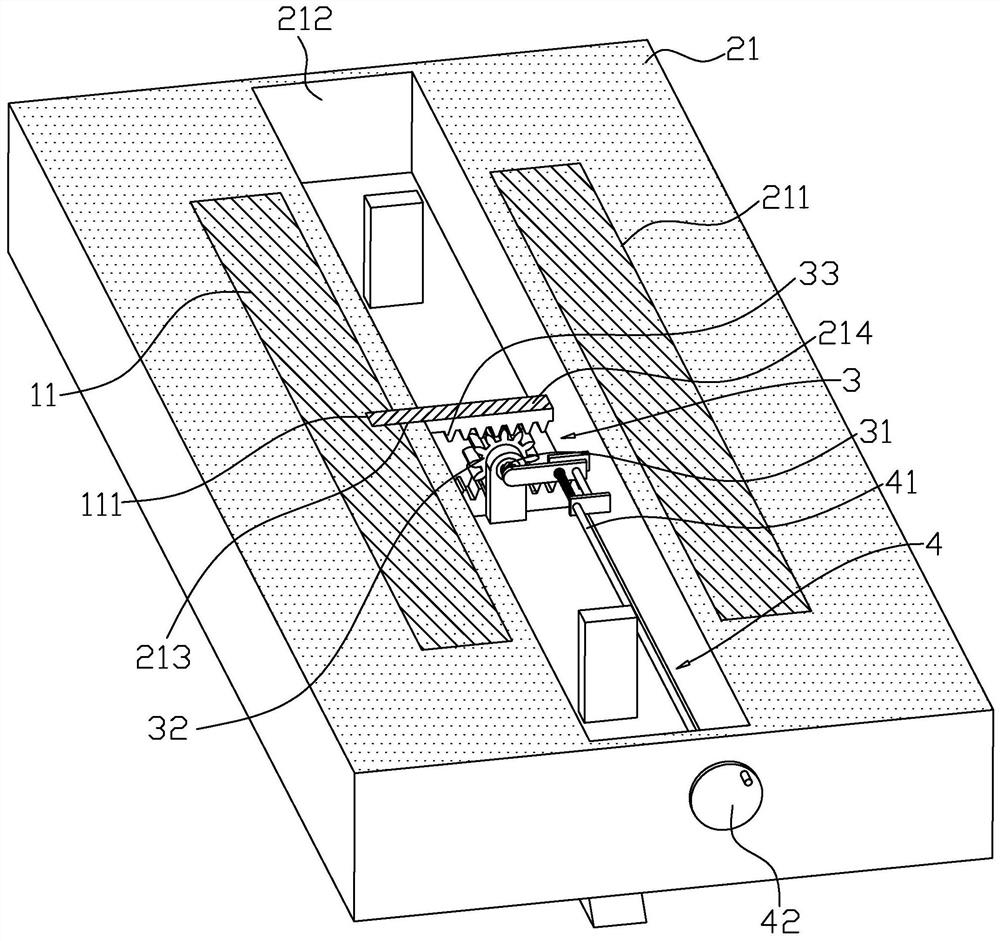

[0038] like figure 2 and image 3 As shown, the bottoms of the opposite ends of the adjacent two bridge bodies 1 are respectively fixed with first insert blocks 11, and the top of the horizontal plate 21 is provided with two first slots 211, and the two first insert blocks 11 are respectively inserted into Two first slots 211; an inner cavity 212 is opened in the horizontal plate 21, first through holes 213 are respectively opened on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com