An assembled aluminum alloy staircase formwork

A stair board and aluminum alloy technology, which is applied in the field of assembled aluminum alloy stair formwork, can solve the problems of large overall structure of stair formwork, inconvenient construction, and influence on the handling of stair formwork.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

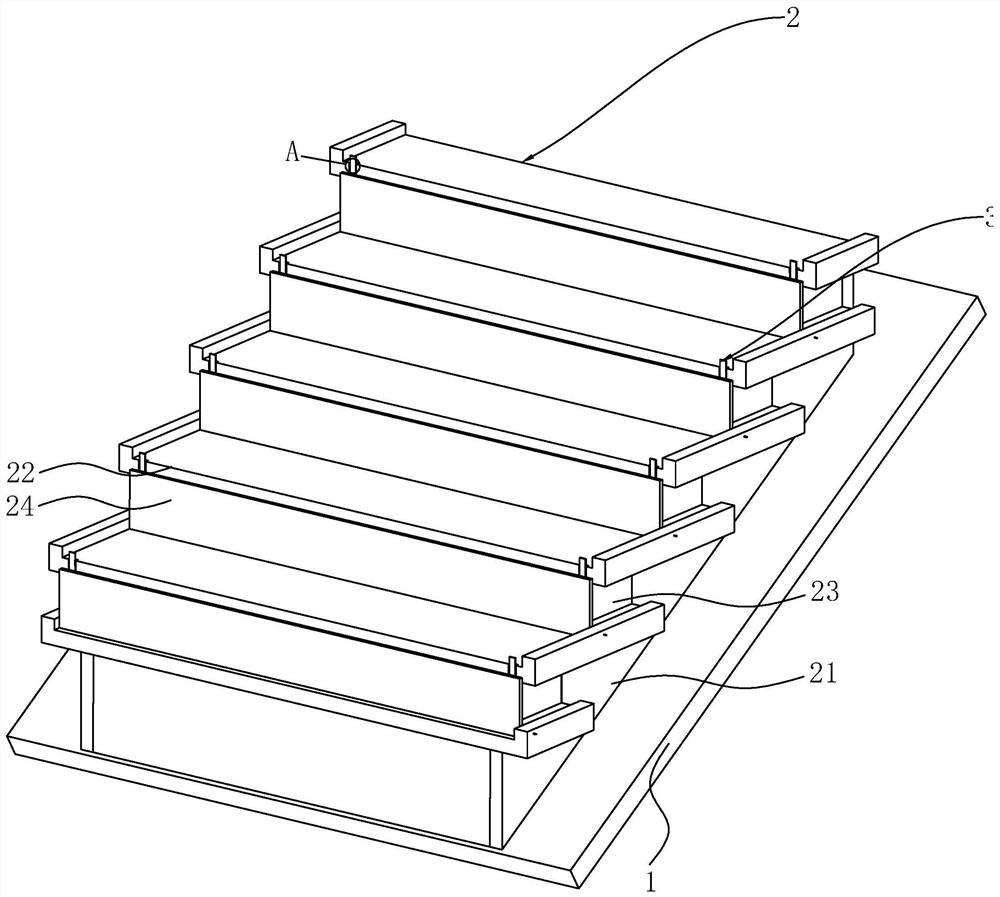

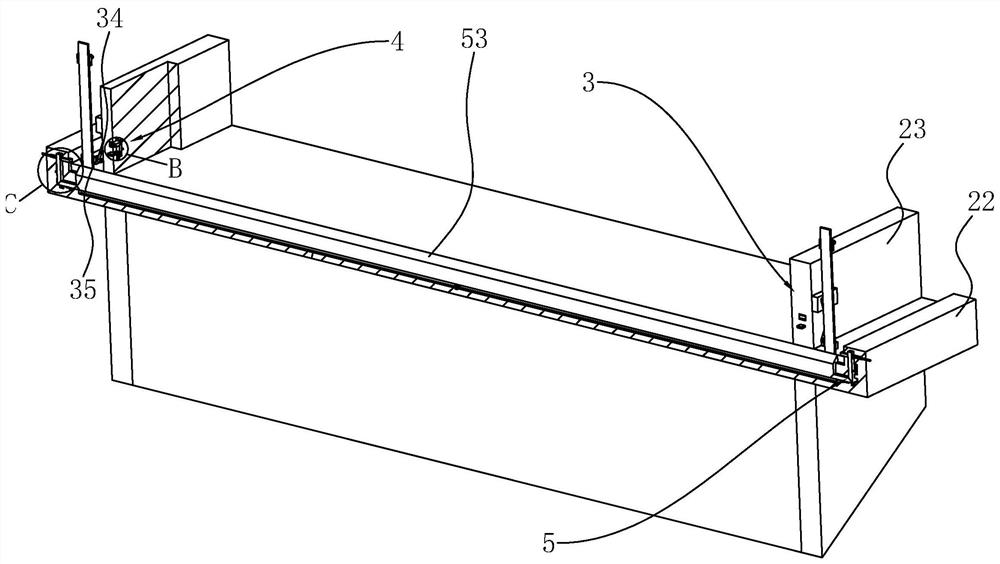

[0034] Embodiment: a kind of fabricated aluminum alloy stair formwork, such as figure 1 As shown, it includes a diagonal brace 1 and multiple sets of stair modules 2 fixed on the top of the diagonal brace 1 . Each set of stair modules 2 includes two oppositely arranged support plates 21 fixed on the top of the slanting brace 1 , a transverse stair plate 22 fixed on the top of the two support plates 21 , and two fixed plates fixed on the top of the transverse stair plate 22 23 and the vertical stair plate 24 that is rotatably installed on the horizontal stair plate 22 away from the diagonal bracing plate 1 side. The side of the fixing plate 23 away from the vertical stair slab 24 is fixedly connected with the side of the support plate 21 away from the diagonal bracing plate 1 through bolts. Two sets of rotating devices 3 for driving the vertical stair boards 24 to rotate are arranged between the horizontal stair boards 22 and the vertical stair boards 24 . Before pouring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com