X-ray cable detection system

A detection system and optical cable technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of low picture definition, inconspicuous interface resolution, and inaccurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

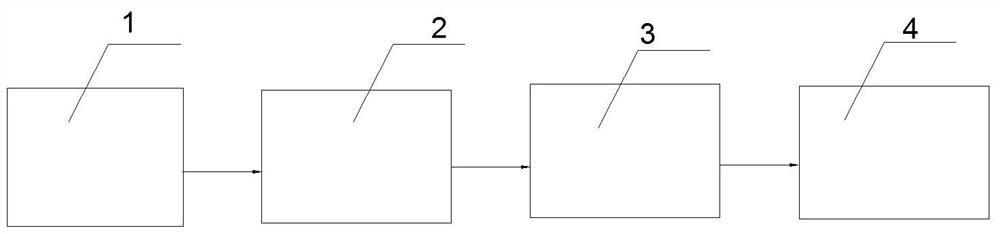

[0028] An X-ray cable detection system includes an image acquisition module, an image processing module connected to the image acquisition module, and an intelligent judgment module connected to the image processing module.

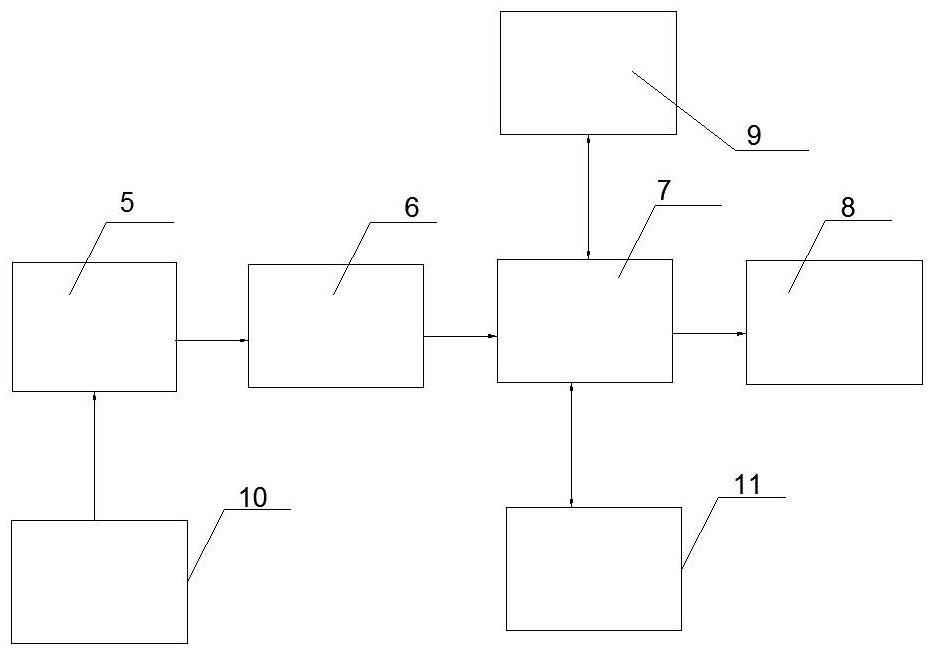

[0029] The image acquisition module includes an image intensifier 3 for receiving X-rays, an optical camera 4 connected to the image intensifier, and the optical camera 4 includes an optical lens and a CCD image sensor 5 .

[0030] The image processing module includes an image preprocessing unit and an image processing unit.

[0031]Described image preprocessing unit comprises the A / D that is connected with described CCD image sensor 5 and signal processing unit 6, the image processor 7 that is connected with described A / D and signal processing unit 6, and described image processor 7 is respectively connected to the SRAM array 9 and the FLASH program memory 10 for signals, and the image processor 7 is connected to the Camlink interface 8 .

[0032] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com