Method for evaluating abradability of sealing coating and application thereof

A technology of sealing coating and evaluation method, which is applied in the aerospace field and can solve problems such as inability to evaluate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] A method for evaluating the abradability of a sealing coating, the evaluation method comprising the following steps:

[0086] (1) Take the NiSi-20 boron nitride sealing coating sample prepared by plasma spraying process, the coating thickness is 2mm, the substrate thickness is 6mm, the coating sample size is 100mm×60mm×6mm, and the substrate material is superalloy.

[0087] (2) Take the TA11 titanium alloy simulation blade, the blade tip size is 0.7mm×20mm, use the TA025A spiral micrometer to measure the 20.142mm before the test.

[0088](3) Put the sealing coating samples and simulated blades in steps (1) and (2) on the BKY-HVT300 / 800 high-temperature and high-speed wearable testing machine developed by Mining and Metallurgy Technology Group Co., Ltd., and install The radius of the testing machine behind the blade sample is 237.5mm.

[0089] (4) Then carry out high-temperature rubbing. The specific method of the high-speed rubbing test refers to clamping the alloy sim...

Embodiment 2

[0096] A method for evaluating the abradability of a sealing coating, the evaluation method comprising the following steps:

[0097] (1) ~ (3), with embodiment 1;

[0098] (4) Then carry out high-temperature rubbing. The specific method of the high-speed rubbing test refers to clamping the alloy simulated blade on the outer edge of the wheel that can rotate at high speed, and coating the alloy substrate with the sealing coating to be tested. It is mounted on a platform that can move forward and backward relative to the wheel, and the sealing coating is heated by a high-speed flame. When the wheel rotates at a certain speed, the platform drives the sealing coating to the wheel at a certain speed. The disc moves to realize the high-speed grinding between the blade and the sealing coating.

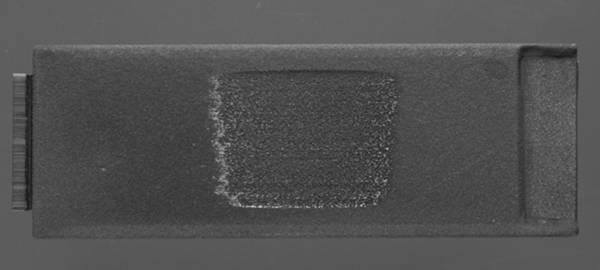

[0099] Set the parameters of the high-temperature rubbing test as follows: temperature 20°C, linear velocity 100m / s, penetration rate 50μm / s, set penetration depth 1000μm, complete the rubbi...

Embodiment 3

[0101] A method for evaluating the abradability of a sealing coating, the evaluation method comprising the following steps:

[0102] (1) ~ (3), with embodiment 1;

[0103] (4) Then carry out high-temperature rubbing. The specific method of the high-speed rubbing test refers to clamping the alloy simulated blade on the outer edge of the wheel that can rotate at high speed, and coating the alloy substrate with the sealing coating to be tested. It is mounted on a platform that can move forward and backward relative to the wheel, and the sealing coating is heated by a high-speed flame. When the wheel rotates at a certain speed, the platform drives the sealing coating to the wheel at a certain speed. The disc moves to realize the high-speed grinding between the blade and the sealing coating.

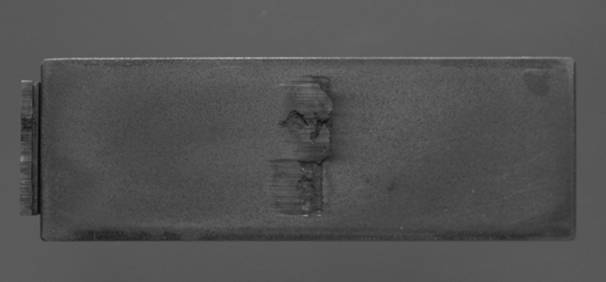

[0104] Set the parameters of the high-temperature rubbing test as follows: temperature 1200°C, linear velocity 520m / s, penetration rate 50μm / s, set penetration depth 1000μm, complete the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com