On-line slag removal device for heating furnace

A heating furnace and slag removal technology, which is applied in the direction of descaling devices, lighting and heating equipment, furnaces, etc., can solve the problems of reduced production efficiency, large impact on continuous production, and limited length of slag removal equipment, and achieves easy use and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

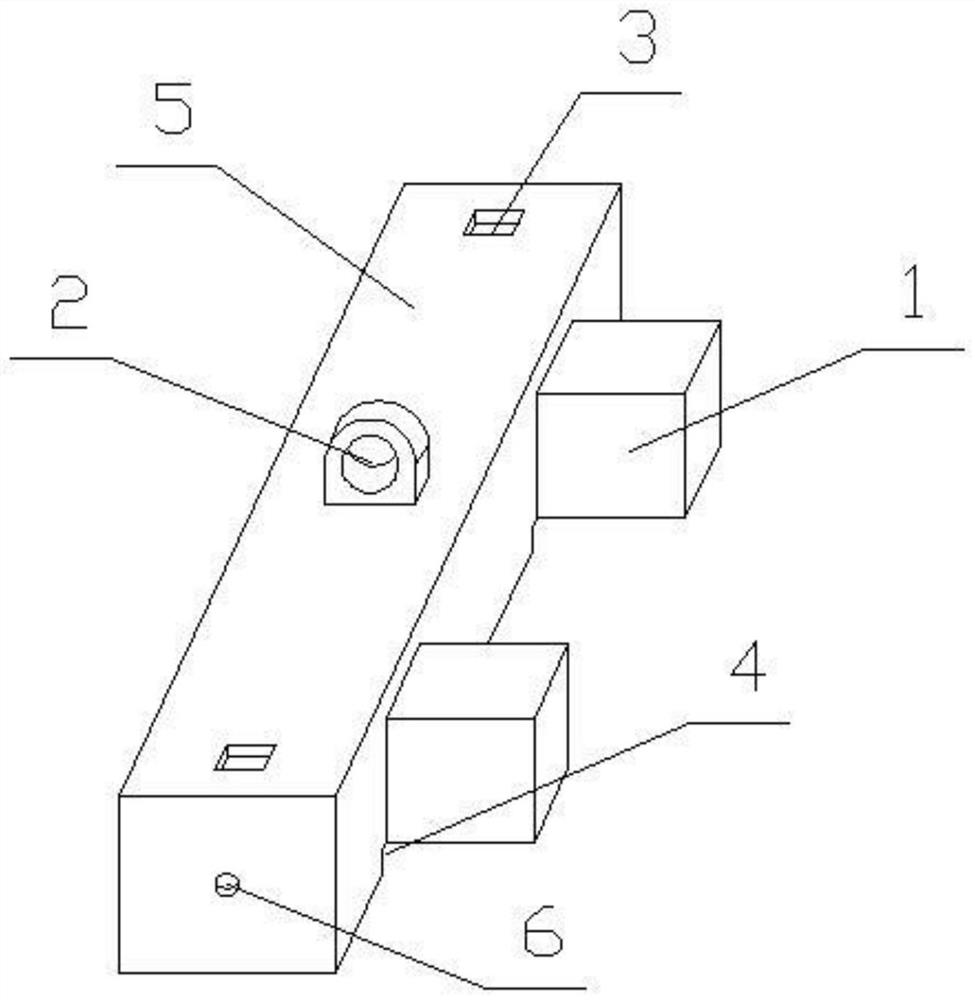

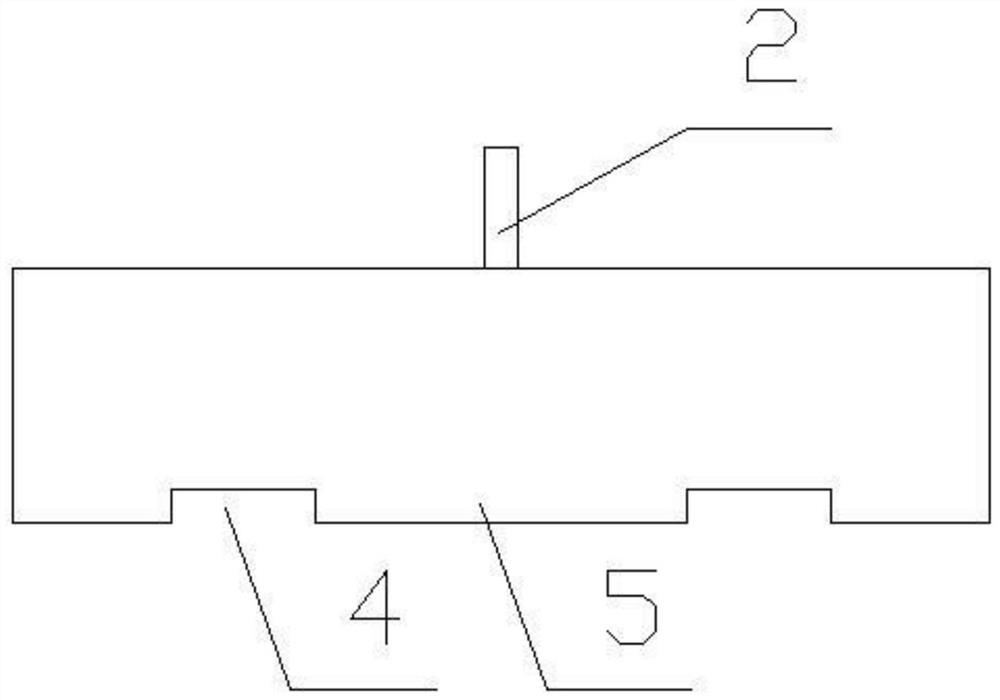

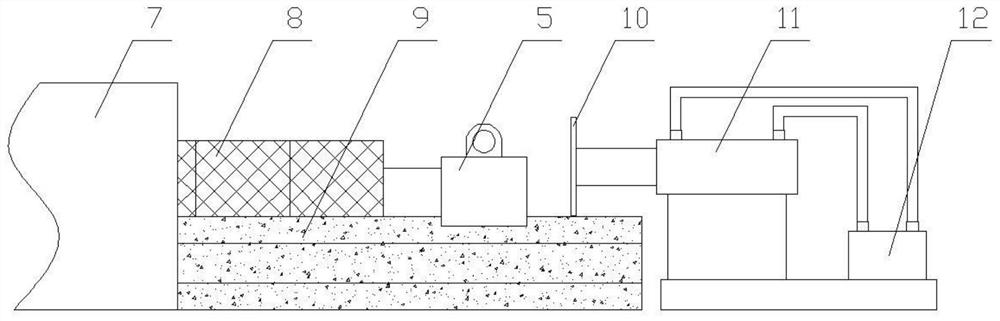

[0019] Embodiment 1, as shown in the figure: an online slag removal device for a heating furnace, including a slag removal body 5, the two ends of the top surface of the slag removal body 5 are provided with rectification grooves 3, and the slag removal body 5 The center of the top end surface of the slag cleaning body 5 is provided with a lifting lug 2, two limit grooves 4 are opened on the bottom end surface of the slag cleaning body 5, and correction holes 6 are opened on both ends of the slag cleaning body 5, so that Two symmetrical support blocks 1 are provided on one side of the slag cleaning body 5 described above. The slag removal body 5 is arranged on a slideway 9, one end of the slideway 9 is provided with a heating furnace body 7, and the other end of the slideway 9 is provided with a propulsion device, and the propulsion device includes a pusher plate 10, hydraulic cylinder 11 and hydraulic press 12, the hydraulic press 12 is connected to the hydraulic cylinder 11 ...

Embodiment 2

[0020] Embodiment 2, a kind of online slag cleaning method of heating furnace, the steps are as follows:

[0021] 1) During the feeding process of the heating furnace, hang the hook of the indoor crane on the lifting lug 2;

[0022] 2), hoist the slag cleaning body 5 above the slideway 9 through the indoor crane;

[0023] 3), the worker corrects the angle and orientation of the slag removal body 5 through the correction hook or the hook, and the worker uses the correction hook or the hook and can correct the slag removal body 5 through the correction groove 3 and the correction hole 6;

[0024] 4) With the help of the worker, the indoor crane hangs the slag-cleaning body 5 on the slideway 9. At this time, the worker turns on the propulsion device, so that the slag-cleaning body 5 slowly moves to the inside of the heating furnace body 7, and starts to heat The accumulated slag on the slideway 9 in the furnace body 7 is cleaned up;

[0025] 5), the slag removal body 5 is pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com