Water-cooled cooling-water machine

A chiller, water-cooled technology, used in refrigerators, refrigeration components, mechanical equipment, etc., can solve the problems of whistling, valve core easy to vibrate, valve core low natural frequency, etc., to achieve good use effect, not easy to resonance, The effect of increasing the natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

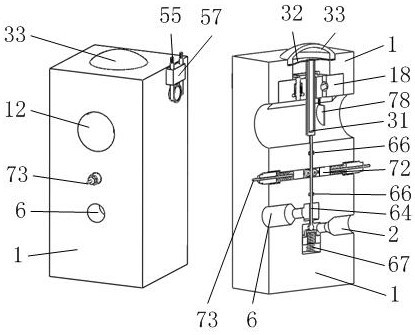

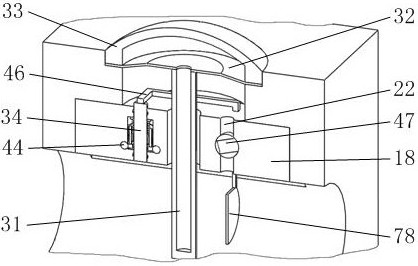

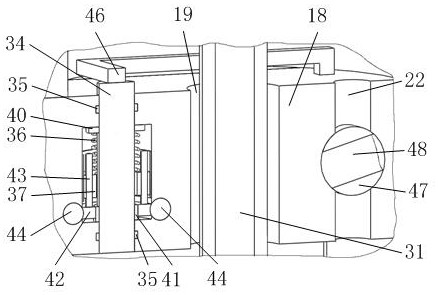

[0047] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0048] Such as figure 1 As shown, it includes a refrigeration cycle, a condenser water cooling heat dissipation cycle, and an evaporator cold water control cycle. It is characterized in that: the expansion valve in the refrigeration cycle includes a valve housing 1, a fixed block A18, a push rod A31, a diaphragm 32, and a sealing cover 33 , pin A34, spring A36, limit rod 46, pin B47, scroll spring 51, push rod B64, ball head 65, spring B67, connecting rod 77, swing plate 78, wherein as figure 2 , 16 As shown in , 17, a fixing block A18 is installed between the accommodation groove C15 used to accommodate the refrigerant in the valve housing 1 and the through groove 11 through w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com