Ditch bottom sludge clearing machine for hydraulic engineering and clearing method

A water conservancy project and cleaning machine technology, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. It can solve the problems of large scale of water conservancy projects, environmental impact, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

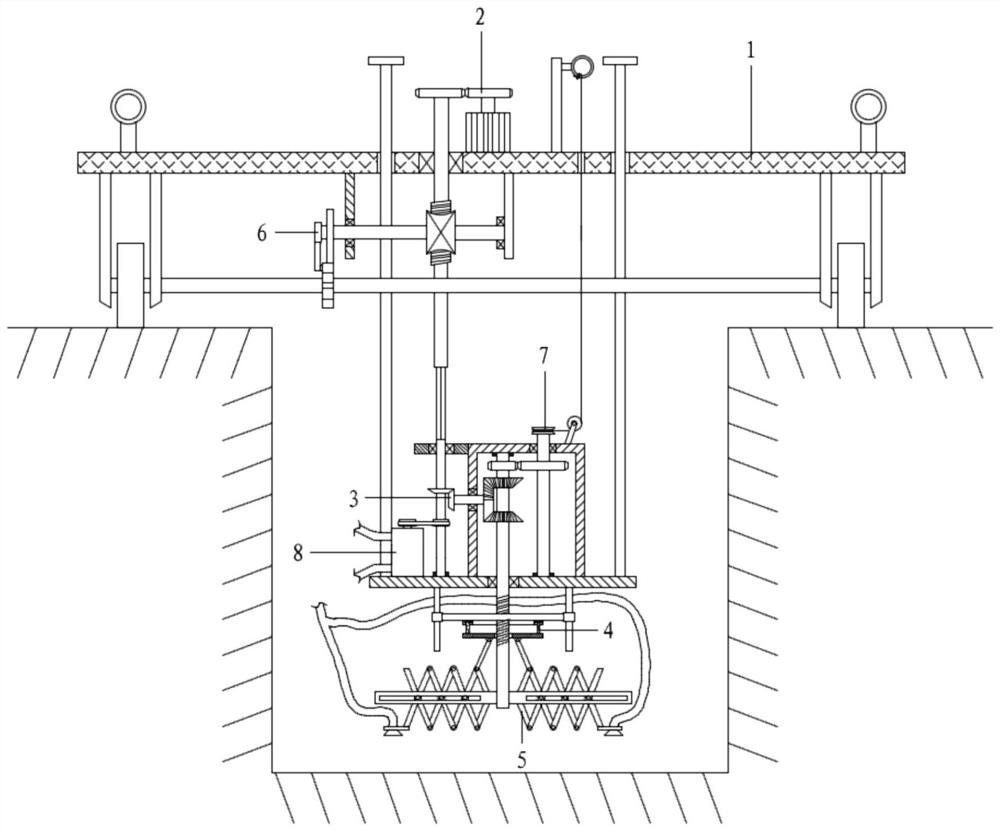

[0074] With reference to the accompanying drawings, a canal bottom sludge cleaning machine for water conservancy projects includes a car body assembly 1, a drive assembly 2, a reciprocating assembly 3, a push-pull assembly 4, a mud mixing assembly 5, and a walking assembly 6;

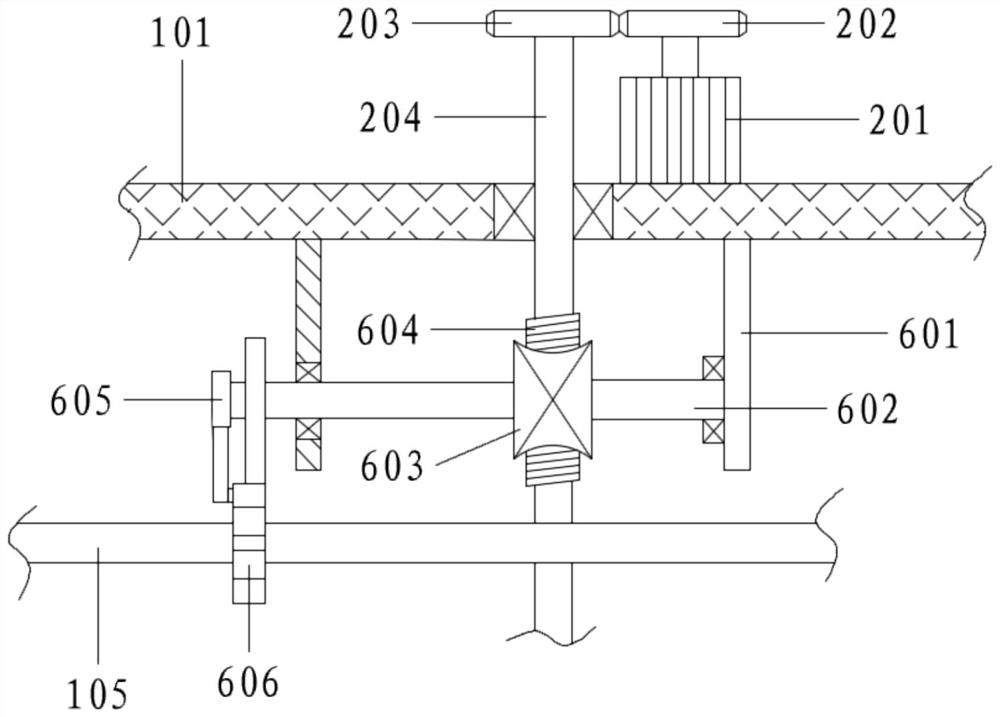

[0075] The vehicle body assembly 1 includes a vehicle plate 101, lifting lugs 102, wheel frames 103, wheels 104, wheel axles 105, a type of connecting rod 106 and a type of support plate 107; The four corners of the bottom of 101 are fixedly connected with a wheel frame 103, and the wheel frame 103 is connected with a wheel 104 through a wheel shaft 105. The two wheels 104 on the front side are mounted on the same wheel shaft 105, and the two wheels 104 on the rear side are mounted on the same wheel shaft 105. A wheel shaft 105 is provided with a walking assembly 6; a driving assembly 2 is provided on the vehicle board 101, and the walking assembly 6 is connected to the driving assembly 2;

[0076] A ty...

Embodiment 2

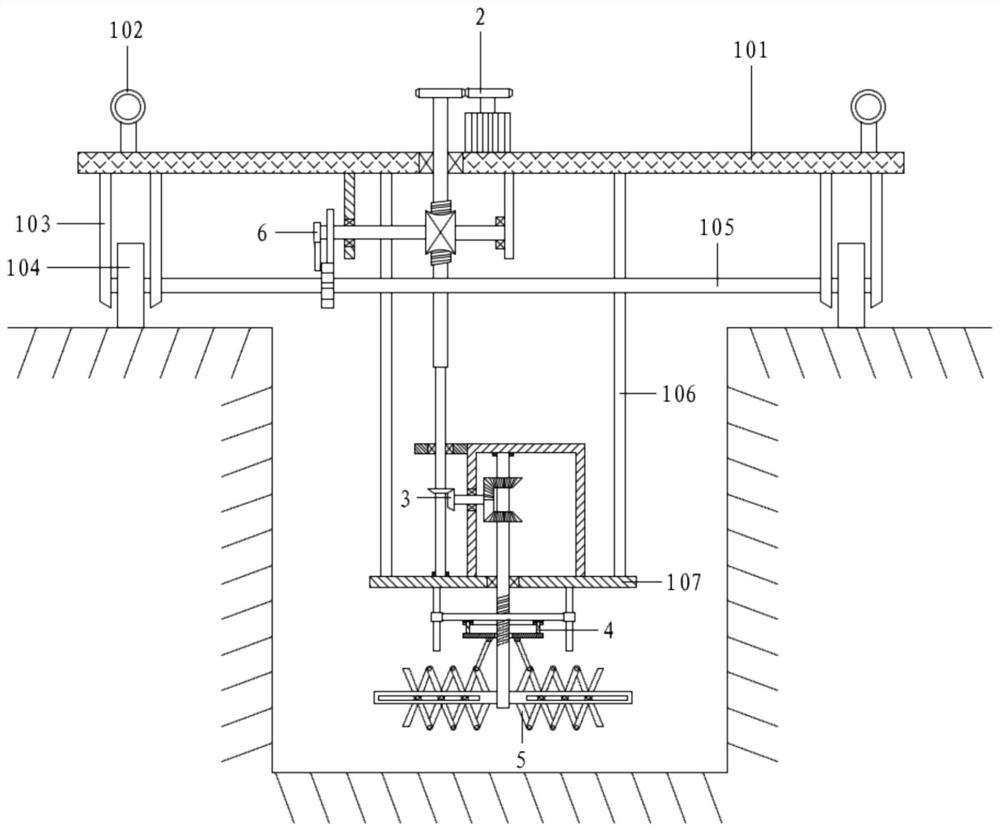

[0078] With reference to the accompanying drawings, a canal bottom sludge cleaning machine for water conservancy projects includes a car body assembly 1, a drive assembly 2, a reciprocating assembly 3, a push-pull assembly 4, a mud mixing assembly 5, and a walking assembly 6;

[0079] The vehicle body assembly 1 includes a vehicle plate 101, lifting lugs 102, wheel frames 103, wheels 104, wheel axles 105, a type of connecting rod 106 and a type of support plate 107; The four corners of the bottom of 101 are fixedly connected with a wheel frame 103, and the wheel frame 103 is connected with a wheel 104 through a wheel shaft 105. The two wheels 104 on the front side are mounted on the same wheel shaft 105, and the two wheels 104 on the rear side are mounted on the same wheel shaft 105. A wheel shaft 105 is provided with a walking assembly 6; a driving assembly 2 is provided on the vehicle board 101, and the walking assembly 6 is connected to the driving assembly 2;

[0080] A ty...

Embodiment 3

[0102] The difference from Embodiment 2 is that the position of the support plate 107 of this embodiment is adjustable.

[0103] In this embodiment, the top end of the first type of connecting rod 106 is not connected to the vehicle plate 101 as in Embodiment 2, and the bottom end of the first rotating shaft 204 is not connected to the top of the second rotating shaft 205 as in Embodiment 2;

[0104] It also includes a lifting assembly 7; the lifting assembly 7 includes a steel wire rope 706, a tether ring 707, a fixed rod 708, a spline shaft 709 and a shaft sleeve 710;

[0105] The bottom end of a first-class connecting rod 106 is connected with a first-class support plate 107, and the top vertically passes through the vehicle plate 101 and is fixedly connected with an anti-off plate 108; a fixed rod 708 is connected above the vehicle plate 101, and a tether is fixedly connected to the fixed rod 708 Ring 707; the top end of the wire rope 706 is connected to the tether ring 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com