Equipment for automatically separating and unloading stacked basket bodies

An automatic separation and equipment technology, applied in loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problems of high work intensity, harsh working environment, multiple auxiliary equipment, etc., to facilitate workshop layout and avoid damage to the basket The effect of physical and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

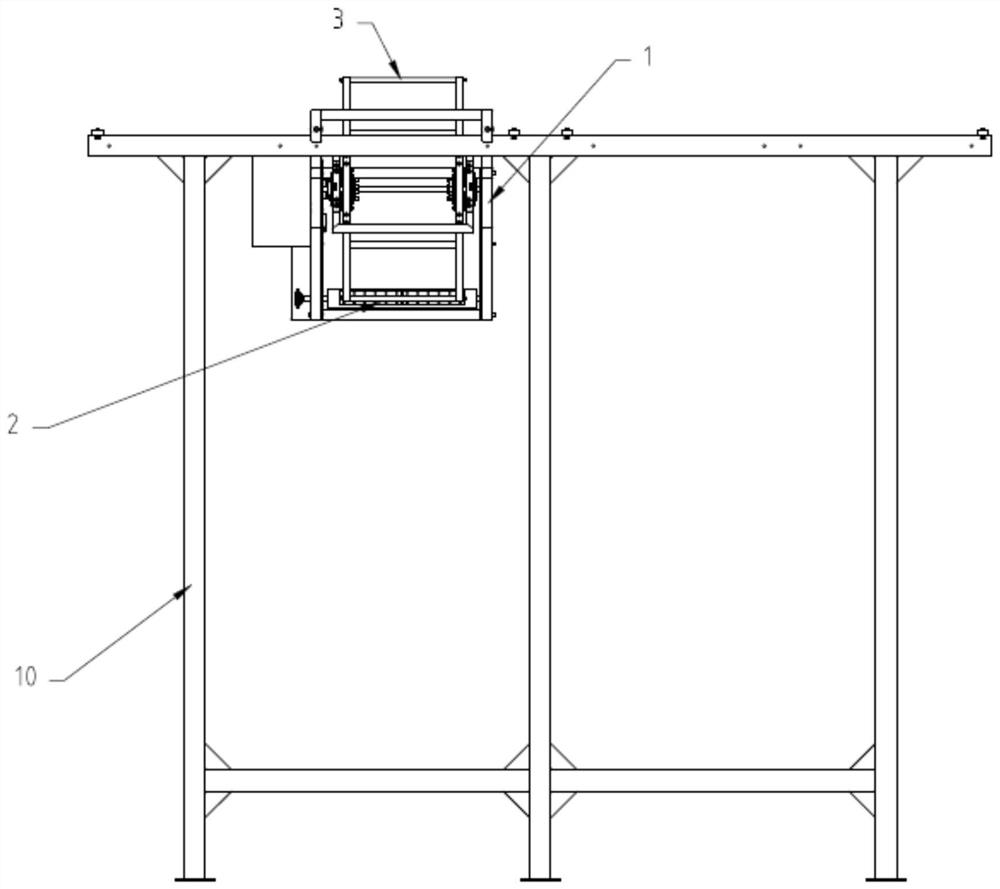

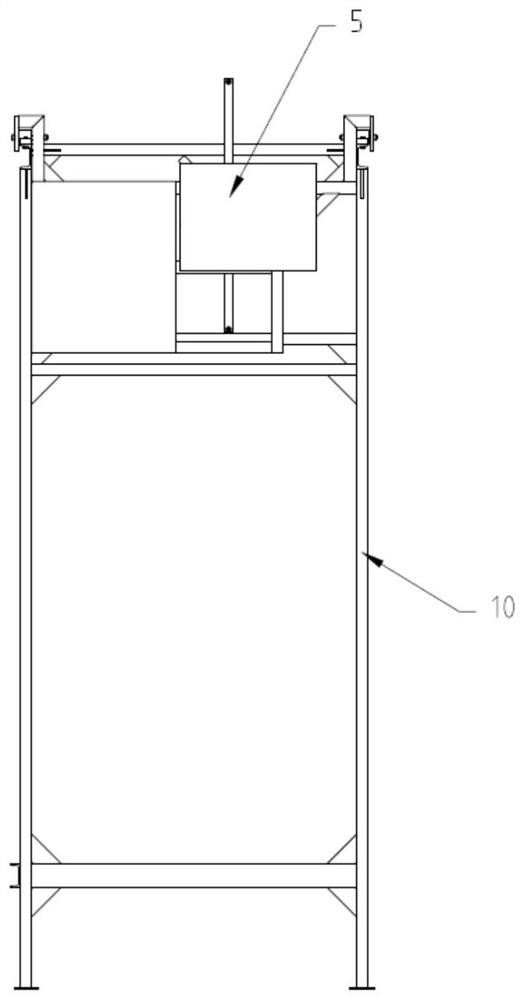

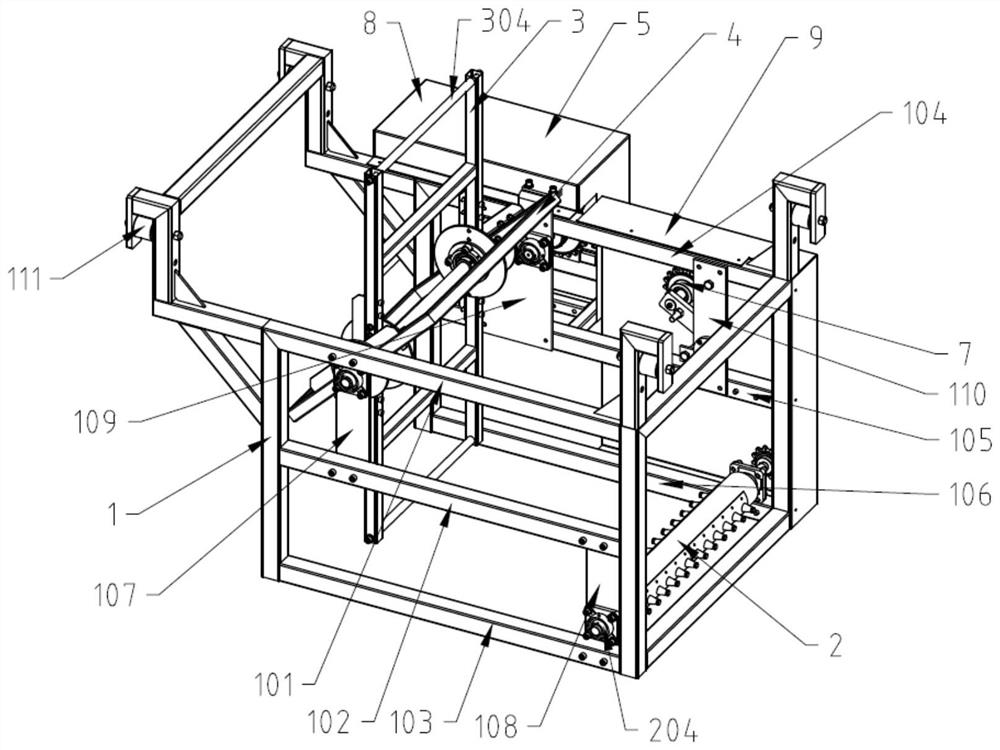

[0045] see Figure 3-Figure 6 , Figure 3-Figure 6 It is a structural schematic diagram of a device for automatically separating and unloading a stack of baskets in this embodiment, including a frame 1, a rotating lifting mechanism 2, a first push rod assembly 3, a second push rod assembly 4, a power drive Assembly 5 and intermediate transmission assembly 6.

[0046] The power drive assembly 5 is arranged at the rear of the frame 1, and includes a motor 501, the output end of which is connected to a first rotating shaft 504, and the first rotating shaft 504 passes through the first push rod assembly 3 and the second push rod assembly 3. The push rod assembly 4 is then connected to the frame 1, wherein the second push rod assembly 4 is fixedly connected to the first rotation shaft 504, and the first push rod assembly 3 is rotatably connected to the first rotation shaft 504, An elastic member is connected between the first push rod assembly 4 and the second push rod assembly 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com