A Zinc Ingot Scraping Robot with Multiple Degrees of Freedom

A robot and degree-of-freedom technology, applied in the field of robots, can solve the problems of difficult and stable manual slag removal effect, high working environment temperature of workers, and high labor intensity, and achieve the effect of obvious slag removal effect, reduction of terminal weight and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

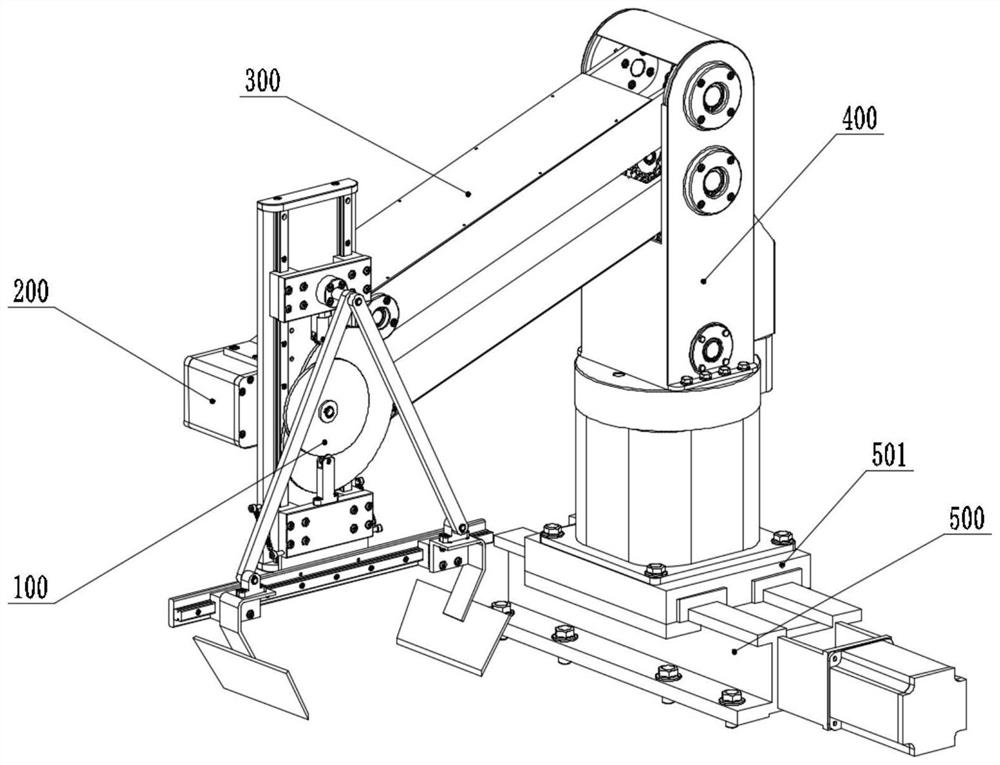

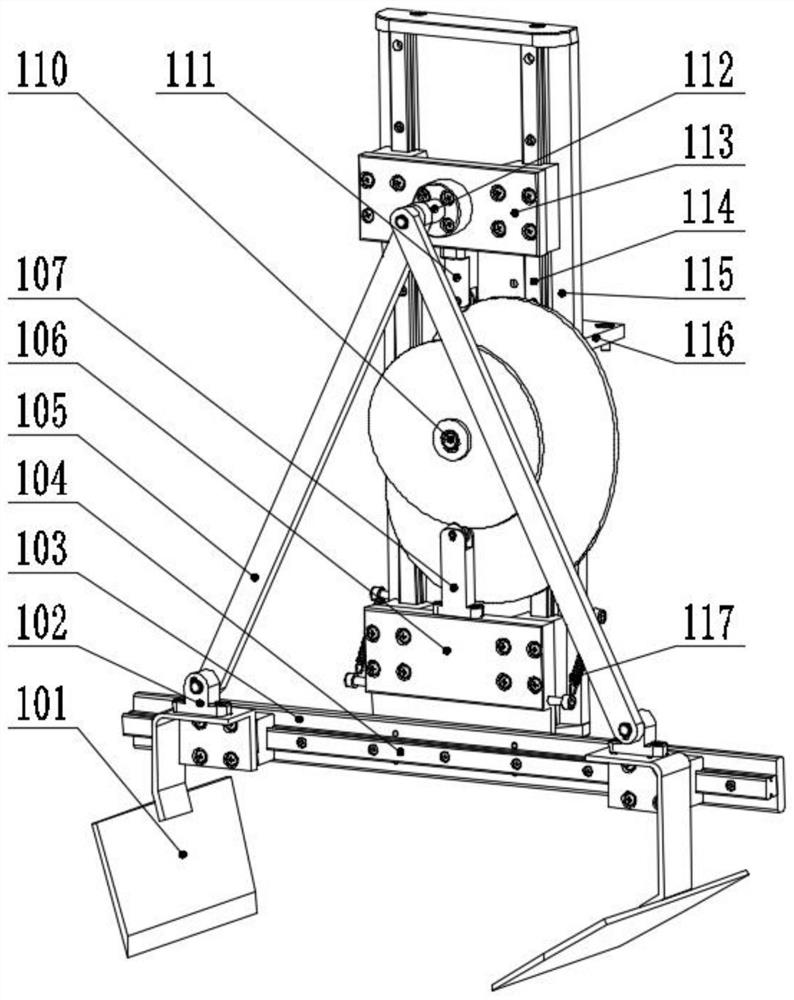

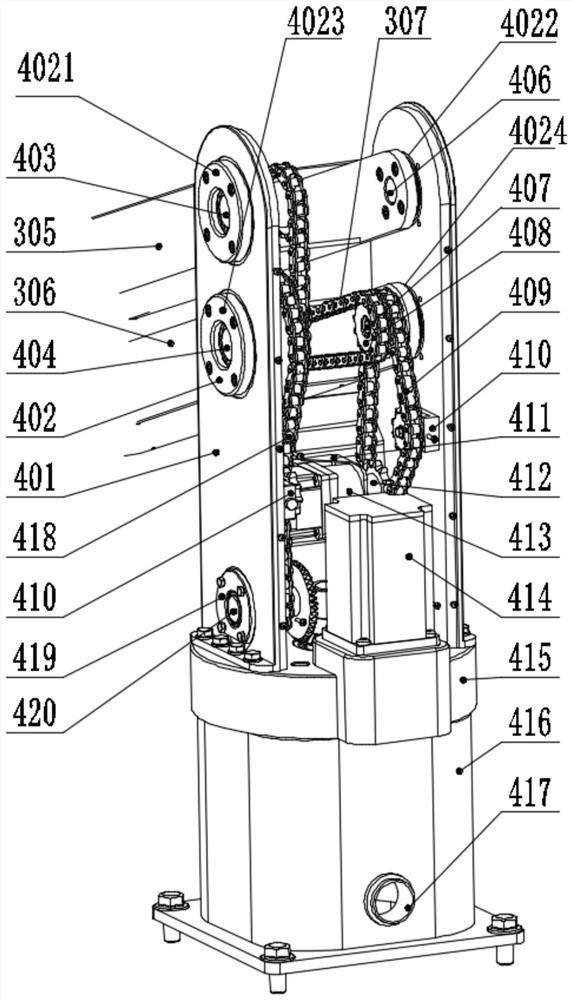

[0032] Embodiment: a kind of multi-degree-of-freedom zinc ingot slag removal robot, such as figure 1 As shown, the lead screw slide table 500 is included, the lead screw slide table 500 is provided with a mobile platform 501, the mobile platform 501 is equipped with a mechanical arm waist 400, the mechanical arm waist 400 is hinged to the arm device 300, and the end of the arm device 300 is provided with There is a wrist device 200, and the actuator 100 is installed on the wrist device 200; figure 2 As shown, the actuator 100 includes a vertical mounting plate 115, on which two vertical sliding rails 114 parallel to each other are arranged in the vertical direction, and the upper and lower ends of the vertical sliding rail 114 are respectively provided with The slider mounting plate 113 and the connecting plate 106, the slider mounting plate 113 and the connecting plate 106 are respectively installed on the four sliders on the vertical slide rail 114. The connecting plate 106 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com