Multi-mode stirring friction welding set, system and method

A friction stir and multi-mode technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as fragile structures, eliminate backlash, improve coaxiality and radial stiffness, and reduce complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

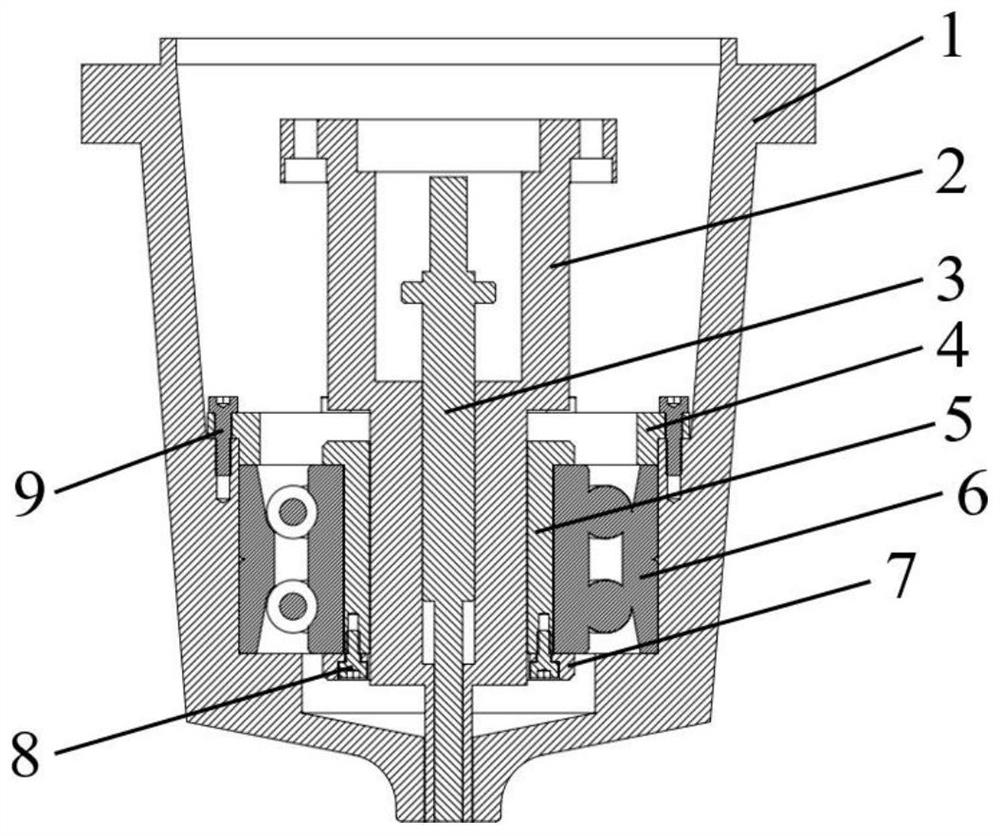

[0088] This embodiment provides a multi-mode friction stir welding welding tool, such as figure 1 As shown, it specifically includes:

[0089] The jacket 1 has an accommodating cavity inside and a through hole at the center of the bottom;

[0090] The sleeve 2 is a hollow tube structure arranged in the accommodation chamber of the jacket 1;

[0091] The stirring needle 3 is arranged in the hollow structure of the sleeve 2 and is coaxial with the sleeve 2;

[0092] The bearing part is set in the accommodating cavity of the jacket 1 and is set outside the sleeve 2;

[0093] The sleeve 2 is sequentially passed through the bearing member and the through hole; the sleeve 2 and the stirring needle 3 can protrude out of the accommodating cavity through the through hole; the sleeve 2 and Stirring pin 3 can be driven by external force to rotate, and can move axially under external force to extend or retract the through hole; there is a first gap between the through hole and the slee...

Embodiment 2

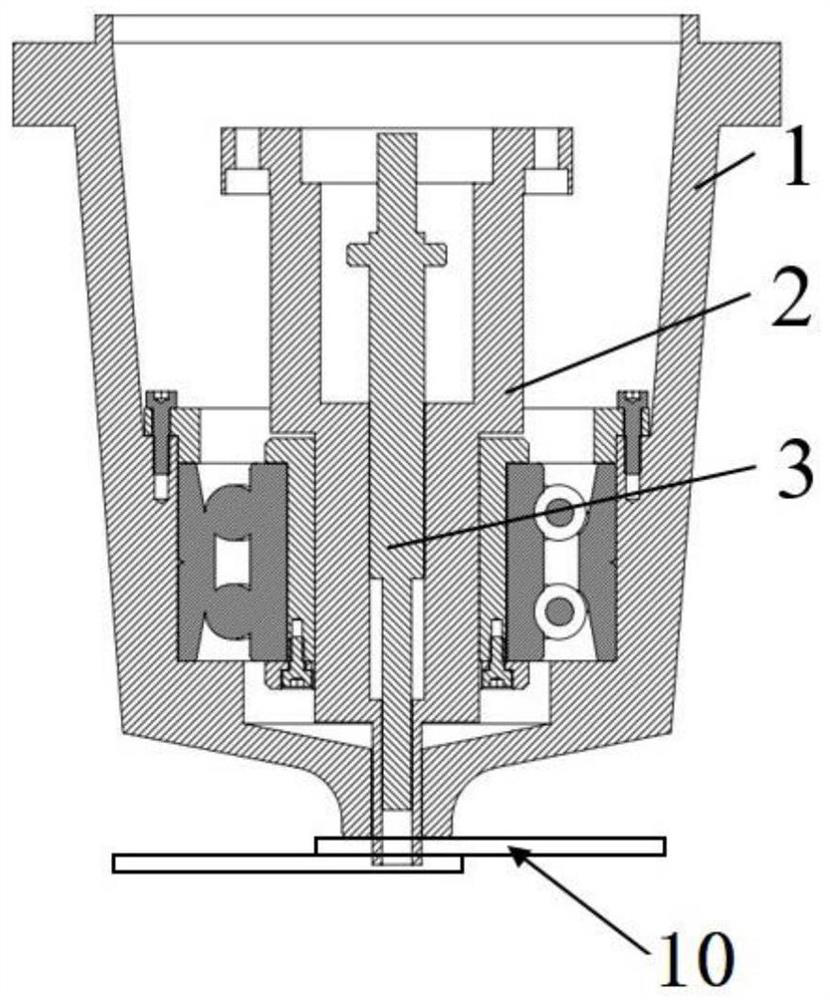

[0104] This embodiment provides a welding method of friction stir spot welding, which uses the multi-mode friction stir welding welding tool described in Embodiment 1. Such as Figure 2a and 2b Two different implementations of friction stir spot welding are shown respectively.

[0105]During welding, the main shaft does not move relative to the workpiece 10 to be welded in a direction parallel to the surface of the workpiece, that is, the horizontal direction is relatively static, and the main shaft moves in a direction perpendicular to the surface of the workpiece, away from the surface of the workpiece to be welded upwards, and close to the surface of the workpiece to be welded for down.

[0106] Such as Figure 2a As shown, it is the spot welding of the cuff 2 under tie mode. The main shaft moves downward to keep the jacket 1 in contact with the upper surface of the workpiece 10 to be welded, and presses the workpiece 10 to be welded; the sleeve 2 penetrates downward in...

Embodiment 3

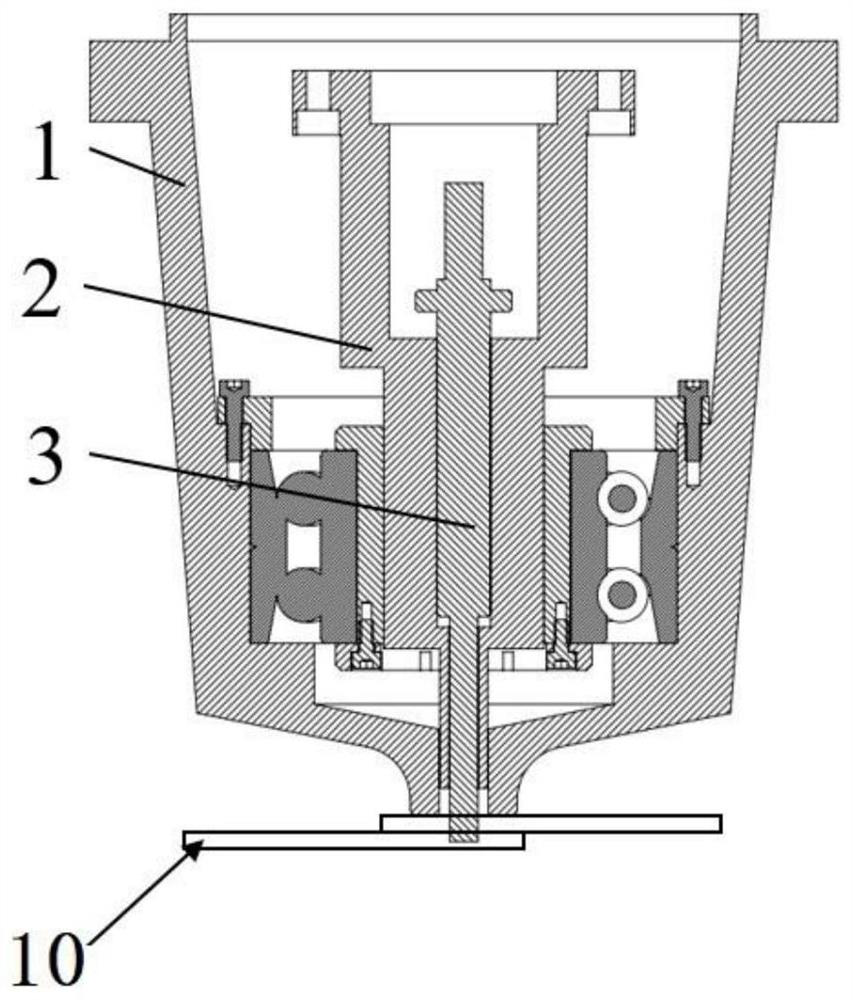

[0110] This embodiment provides a welding method for friction stir seam welding of a movable shoulder, which uses the multi-mode friction stir welding welding tool described in Embodiment 1. image 3 Shows the positional relationship between the sleeve and the stirring pin along the axial direction in the dynamic shoulder welding, Figure 4 It shows the variable welding depth welding mode in the moving shoulder welding.

[0111] Such as image 3 As shown, the lower end surface of the jacket 1 is not in contact with the surface of the workpiece 10 to be welded; the lower end surface of the sleeve 2 is in contact with the surface of the workpiece to be welded to compress the workpiece 10 to be welded; the stirring needle 3 penetrates downward into the workpiece 10 to be welded ; start the main shaft, the main shaft moves relatively in the horizontal direction along the surface of the workpiece 10 to be welded, and the sleeve 2 and the stirring needle 3 rotate in the same direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com