High-strength copper-clad copper wire and preparation method thereof

A high-strength, copper-clad copper technology, applied in the coating process of metal materials, etc., can solve the problems of low overall strength, easy self-cracking, and easy failure, etc., to eliminate residual stress, improve plasticity, and prevent self-cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

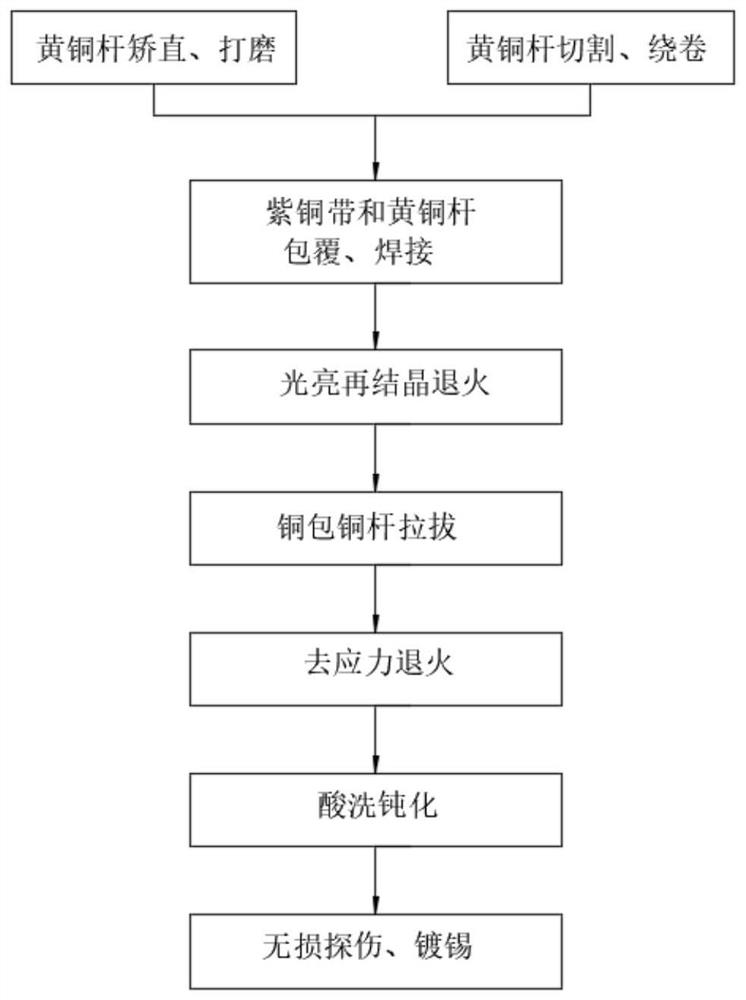

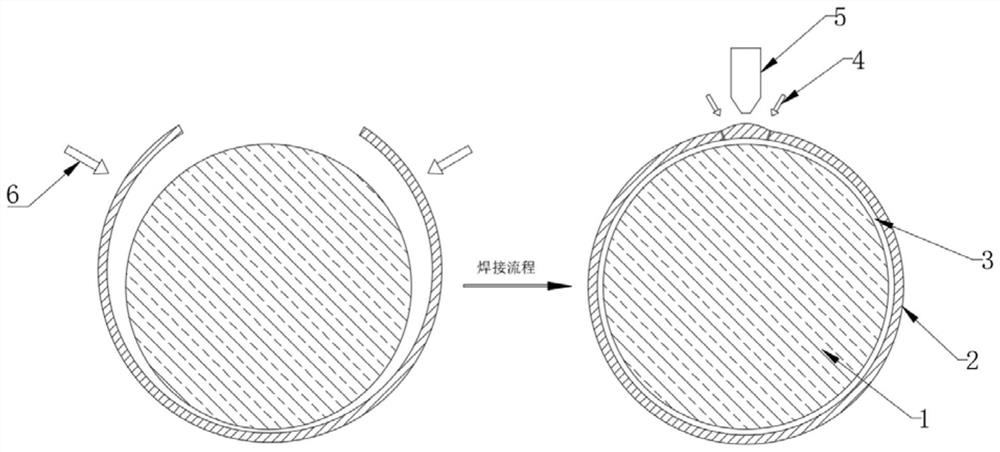

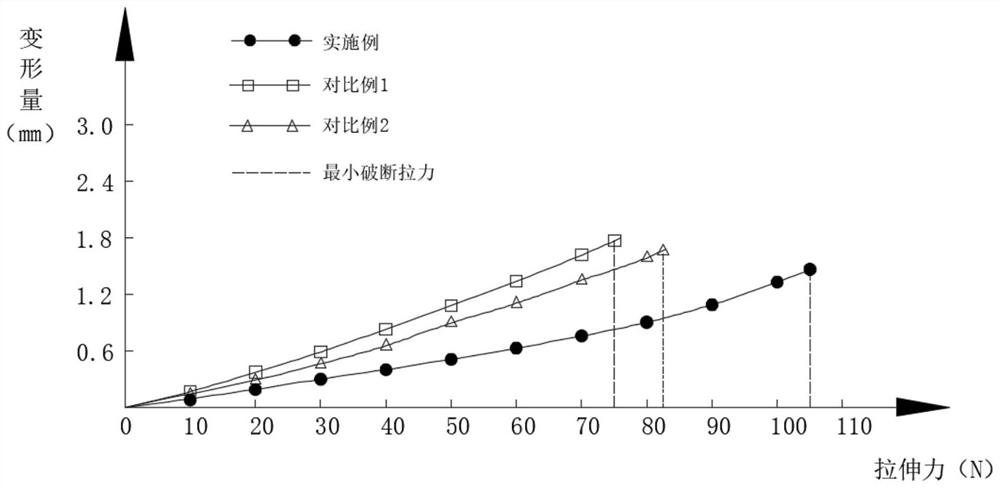

[0026] see Figure 1~3 , in an embodiment of the present invention, a high-strength copper-clad copper wire and a preparation method thereof, comprising a brass rod 1 and a copper strip 2 wrapped on the outer surface of the brass rod 1, the preparation method comprising the following steps:

[0027] S1. Take the brass rod 1 of H65 grade with copper content: 63.0% to 68.5%, and zinc content: 31.5% to 37.0%. Straighten and polish the brass rod 1 in sequence, and then clean and dry the surface of the brass rod 1 deal with;

[0028] S2. Take the copper strip 2 of the T2 brand with a copper content rate of 99.90% and cut it so that the width of the copper strip is equal to the diameter of the brass rod, and polish the trimming of the copper strip, and at the same time wind the cut copper strip into a roll ;

[0029] S3. Extrude and coat the copper strip 2 on the outer side of the brass rod 1 polished by S2 through the coating machine 5, and then perform gas shielded welding on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com