Microparticle machine

A technology of particle and machine base, which is applied in the field of particle machine, can solve the problems of inability to achieve crushing particle size, long drying time, and inability to effectively deal with water separation, so as to improve the effect of crushing and granulation, solve the pain points and difficulties of the industry, and achieve excellent processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

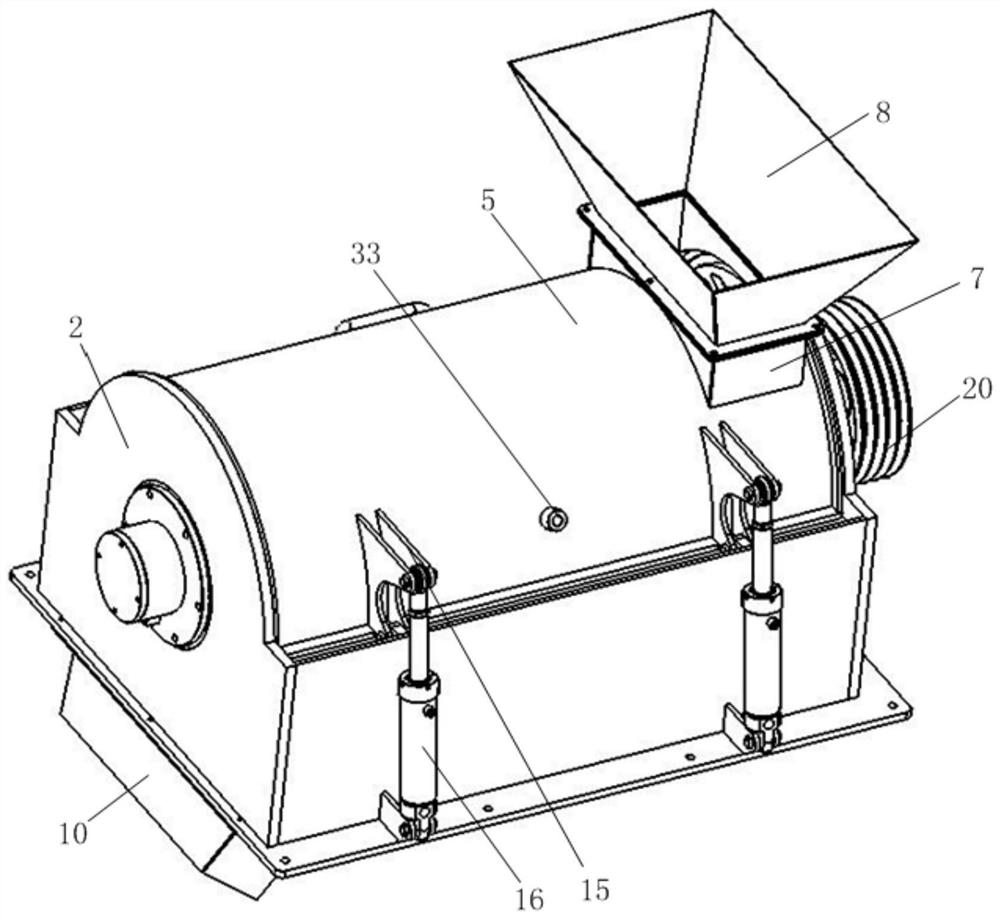

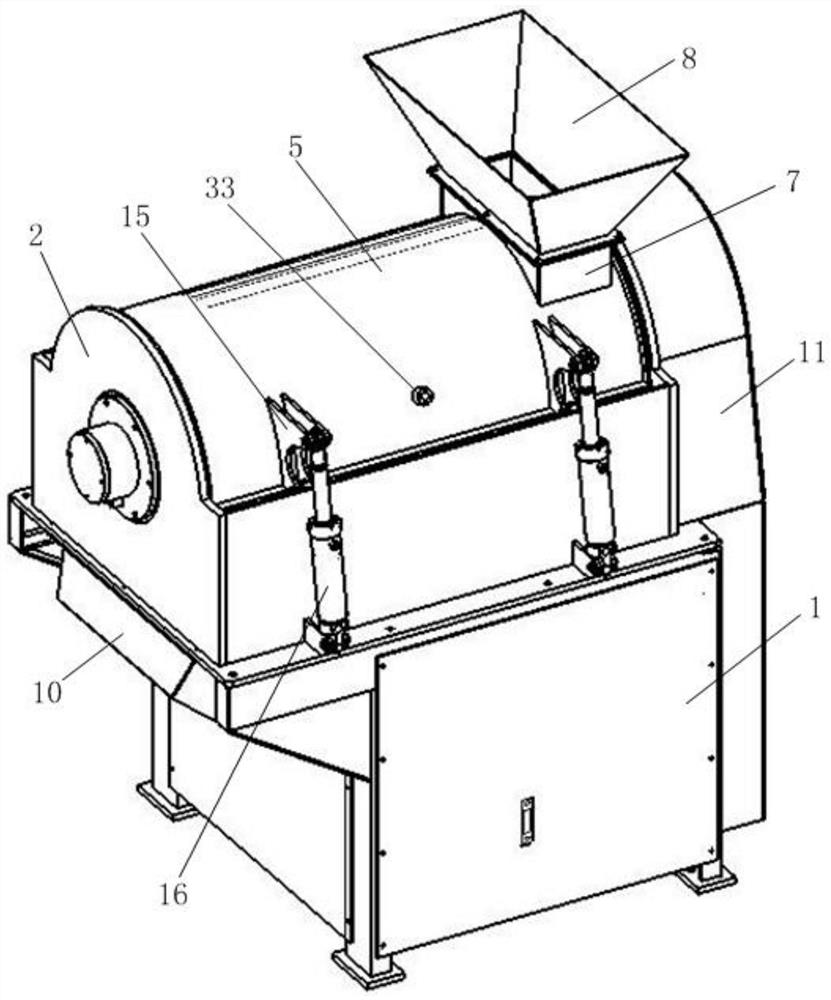

[0045] like Figure 1 to Figure 12 As shown, the particle machine includes a fixedly placed machine base 2, a machine slot 3 that is arranged in the machine base and has a semicircular cross-section, and is opened at the bottom of one end of the machine slot and runs through the discharge port 4 at the bottom of the machine base. A machine cover 5 on the machine base and matched with the machine groove to form a cylindrical crushing space 6, a feed port 7 arranged on the machine base or the machine cover and connected to the other end of the crushing space opposite to the discharge port, The arc-type crushing knife roller 20 that is matched to be arranged in the crushing space and rotatably connected with the base, and the power source 9 for providing operating power for the arc-type crushing knife roll, wherein the base can be used according to the actual application The position is reconfigured with the corresponding lower frame 1; when the feed port is opened on the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com