A secondary processing device for caking pig feed

A secondary processing and pig feed technology, applied in the direction of feed, measuring devices, applications, etc., to achieve good crushing effect and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

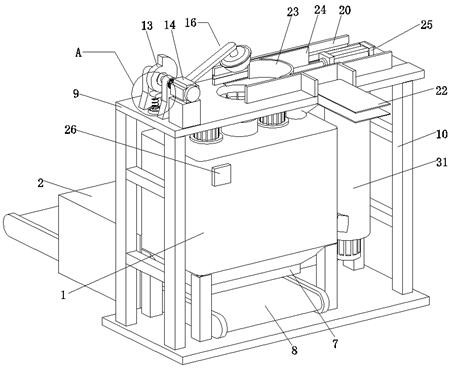

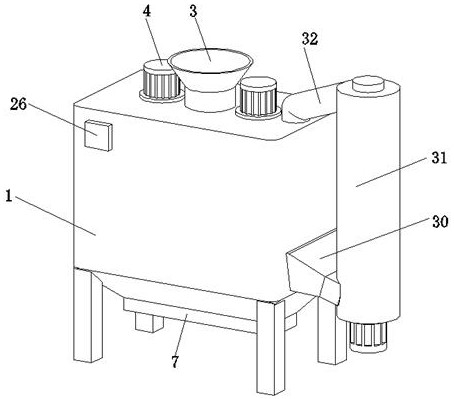

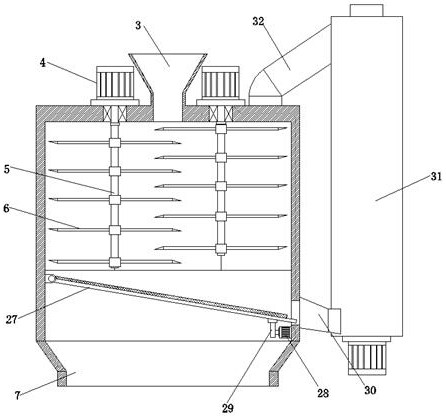

[0034] Embodiment 1 has introduced a kind of secondary processing device that is used for agglomeration pig feed, with reference to appendix figure 1 , attached figure 2 And attached image 3 , its main structure includes a crushing box 1 and a drying box 2, a feeding hopper 3 is arranged at the center of the upper surface of the crushing box 1, and the upper surface of the crushing box 2 located on the left and right sides of the feeding hopper 3 is provided with The pulverizing motor 4, the output shafts of the two pulverizing motors 4 extend into the lower end of the pulverizing box 1 cavity and are connected with pulverizing shafts 5 through couplings (not shown in the figure). A crushing blade 6 arranged in a staggered manner.

[0035] Reference attached figure 1 And attached Figure 4 , the lower end of the crushing box 1 is provided with a discharge port 7, and a first conveyor belt 8 is provided through the drying box 2, and the front end of the first conveyor bel...

Embodiment 2

[0040] Embodiment 2 is a further improvement made on the basis of Embodiment 1, which will be described in detail below.

[0041] Embodiment 2 introduces a secondary processing device for agglomerated pig feed improved on the basis of Embodiment 1, and the same parts as Embodiment 1 will not be described again. The difference is: refer to the appended image 3 , the present embodiment 2 is also provided with a sieve 27 obliquely at the lower end of the inner cavity of the crushing box 1, and the sieve 27 is arranged with a high left and a low slant on the right. The lower right end of the screen 27 is movable, and a vibrating motor 28 is fixed at the lower end of the inner wall on the right side of the crushing box 1, and a dust cover (not shown in the figure) is set outside the vibrating motor 28, and then The output shaft of vibration motor 28 is connected with cam 29, and its cam 29 abuts against the lower right end of screen cloth 27, and the vibration screening of screen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com