Method for debonding sticky fertilized eggs of marine fishes

A fertilized egg, seawater technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of low hatching rate, incompleteness, sticky eggs easy to agglomerate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

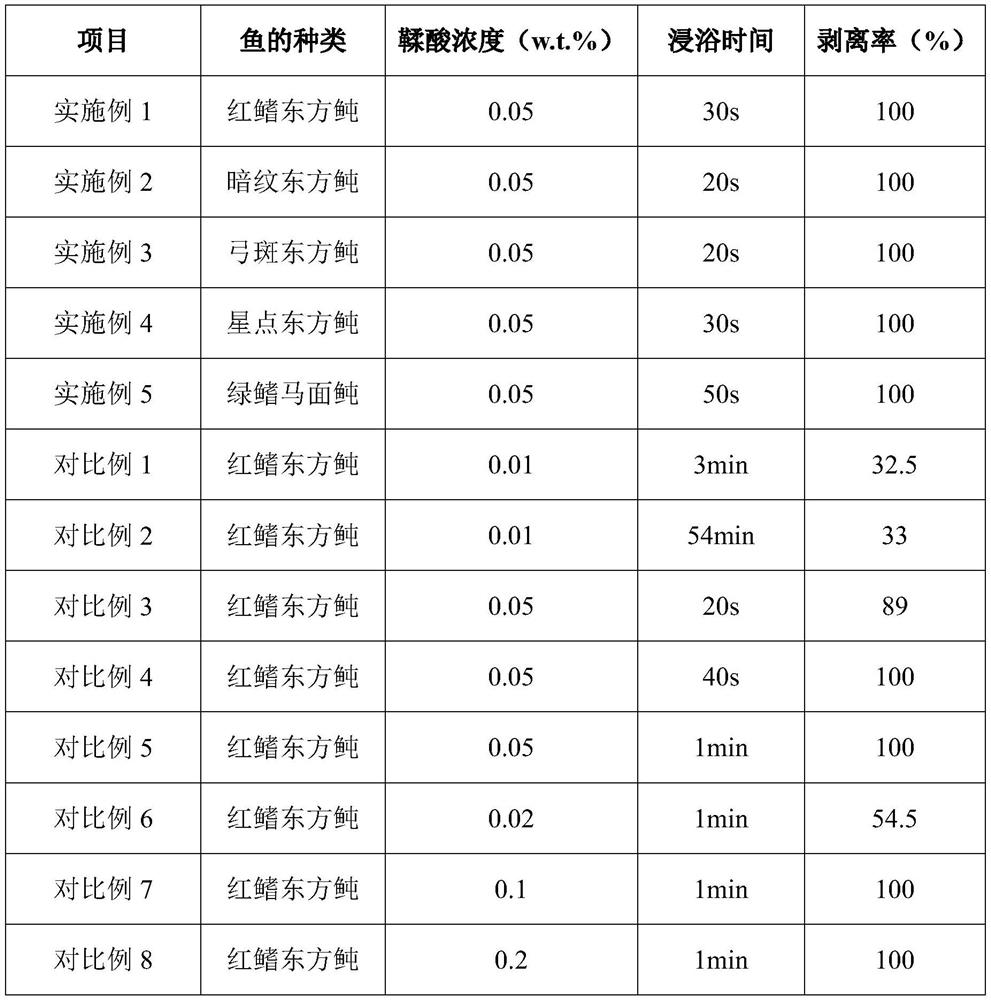

Examples

Embodiment 1

[0020] Taking the viscous fertilized eggs of redfin puffer as an example, they were debonded with tannic acid seawater solution.

[0021] Step 1: preparing a debonding solution; using seawater as a solvent and tannic acid as a solute, preparing a 0.05% tannic acid seawater solution;

[0022] Step 2: aerating and immersing; immersing the fertilized eggs in the tannic acid seawater solution, inflating the water at the same time, fully immersing for 30 seconds;

[0023] Step 3: cleaning and counting; take out the fertilized eggs after soaking, place them in clean seawater for cleaning, and obtain debonded fertilized eggs, then put the debonded fertilized eggs into a petri dish, add clean seawater , let stand for 10min, pour off the seawater, count, and calculate the peeling rate.

[0024] The debonded fertilized eggs were microscopically observed under a dissecting microscope, and then the debonded fertilized eggs were hatched: 200 fertilized eggs were placed in clean seawater i...

Embodiment 2

[0026] Taking the viscous fertilized eggs of puffer puffer as an example, they were debonded with tannic acid seawater solution.

[0027] The mass concentration of the tannic acid seawater solution used is 0.05%, and the time for aerated soaking is 20s. Other operations are the same as in Example 1.

Embodiment 3

[0029] Taking the viscous fertilized eggs of puffer puffer as an example, they were debonded with tannic acid seawater solution.

[0030] The mass concentration of the tannic acid seawater solution used is 0.05%, and the time for aerated soaking is 20s. Other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com