Novel energy-saving and efficient universal heat dissipation device for electromechanical equipment

A technology of electromechanical equipment and heat dissipation device, which is applied in the construction parts of electrical equipment, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of low heat dissipation efficiency of electromechanical equipment, achieve the effect of improving heat dissipation efficiency and reducing dust adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

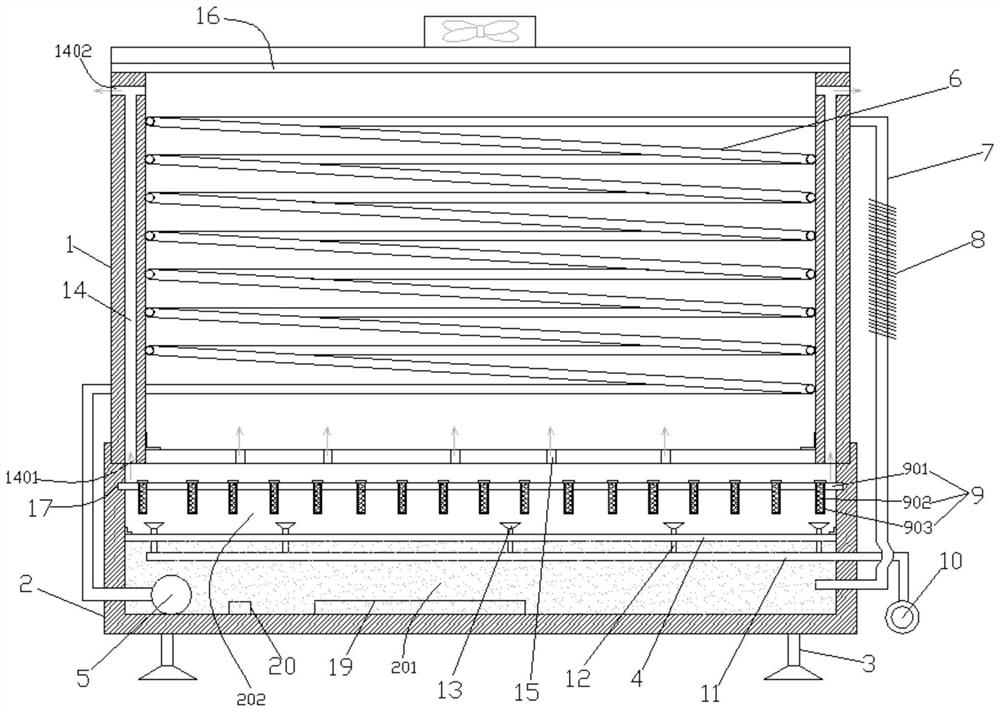

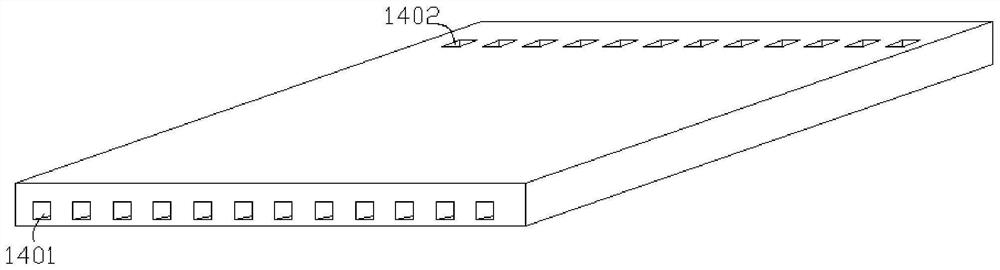

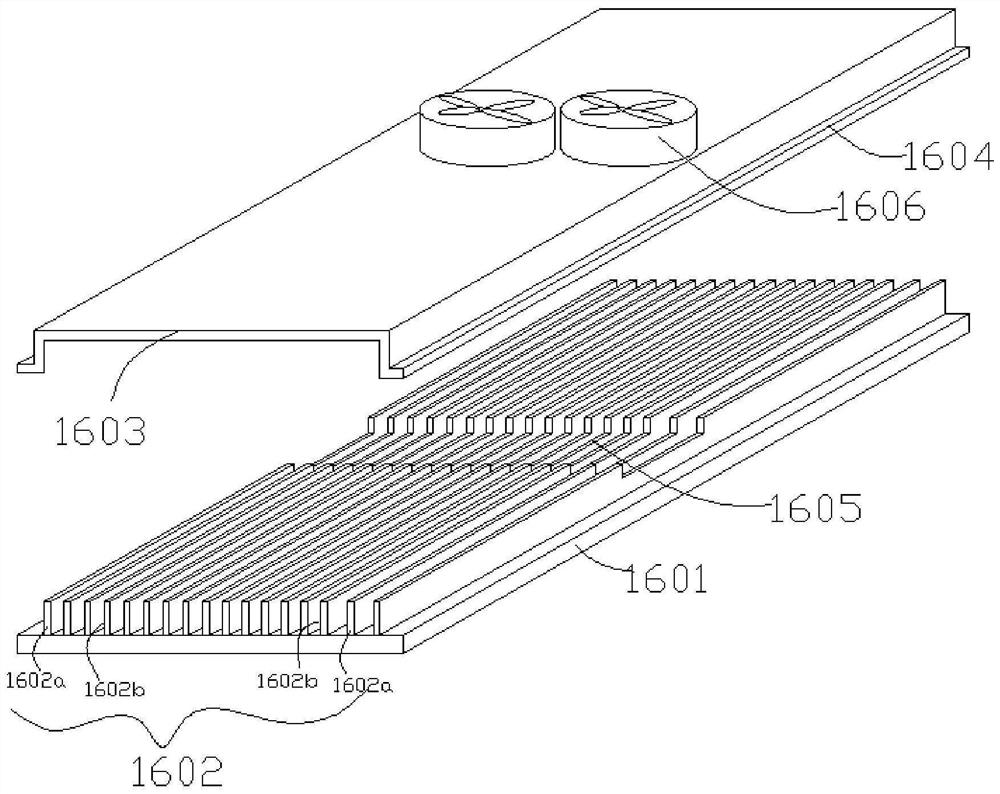

[0032] Such as image 3 As shown, the top heat dissipation mechanism 16 includes a top plate 1601 constituting the top of the electromechanical equipment housing 1. The upper end of the top plate 1601 is provided with a heat sink group 1602 composed of a plurality of heat sinks 1602a arranged side by side. The middle part of the heat sink group 1602 is concave, and the heat sink group 1602 is provided with a door-shaped cover body 1603 that is pressed against the upper ends of a plurality of heat sinks 1602a, and the two ends of the airflow channel 1602b between adjacent heat sink fins 1602a of the heat sink group 1602 are kept unobstructed, and both sides of the door-shaped cover body 1603 are There is an edge 1604 bolted to the top plate 1601, and an airflow chamber 1605 is formed between the door-shaped cover body 1603 and the depression in the middle of the heat sink group 1602, and the airflow chamber 1605 communicates with the airflow channel 1602b between adjacent heat s...

no. 2 example

[0034] Such as Figure 4 As shown, the top heat dissipation mechanism 16 includes a top plate 1601 constituting the top of the electromechanical equipment housing 1. The upper end of the top plate 1601 is provided with a heat sink group 1602 composed of a plurality of heat sinks 1602a arranged side by side. The door-shaped cover body 1603 at the upper end of the plurality of heat sinks 1602a, and the two ends of the airflow channel 1602b between adjacent heat sink fins 1602a of the heat sink group 1602 are kept unobstructed, and both sides of the door-shaped cover body 1603 are provided with bolts connected to the top plate 1601 The edge 1604 of the door-shaped cover 1603 is provided with an airflow chamber 1605 communicating with the airflow channel 1602b between adjacent heat sinks 1602a of the heat sink group 1602, and two sets of impeller fans 1606 are arranged inside the airflow chamber 1605.

[0035] Such as Figure 5 As shown, in this embodiment, the filter layer 9 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com