Method for eliminating gear clearance error influence and related product

A gear gap and gear technology, applied in electrical components, control systems, motor generator control and other directions, can solve problems such as instrument pointer indication errors, and achieve the effect of reducing correction time and eliminating inaccurate display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application.

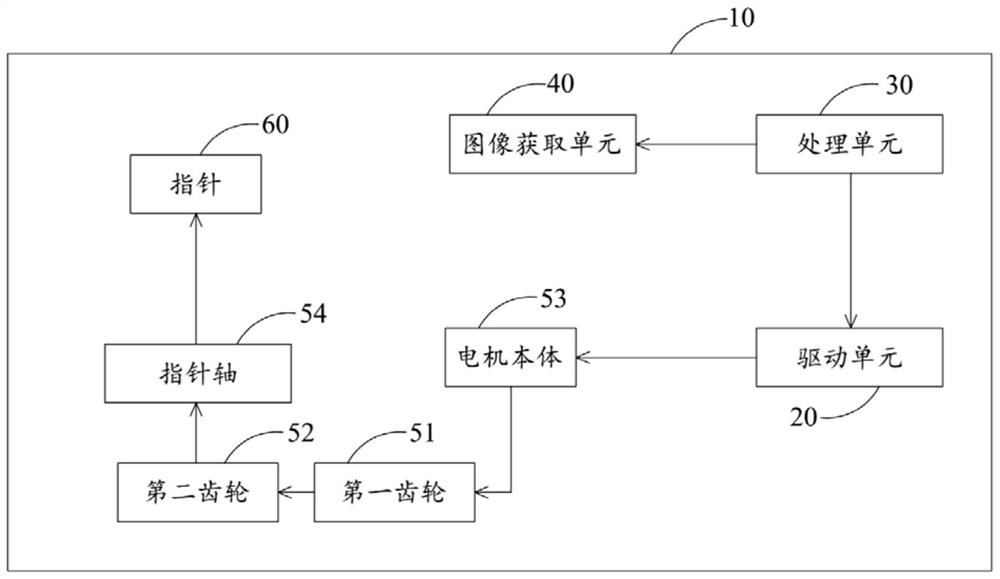

[0077] The embodiment of the present application provides a method for eliminating the influence of the gear gap error, which is used to eliminate the indication error caused by the gap between the first gear and the second gear of the stepping motor gear; so that the indication value of the automobile instrument is accurate, Improve driving experience.

[0078] Please refer to figure 2 , and synchronize the reference Figure 1a and Figure 1b , the method includes but is not limited to the following steps:

[0079] 101: Control the stepping motor to drive the first gear to rotate in the first direction, wherein, when the first gear rotates in the first direction, the first gear drives the second gear to rotate, and the pointer is connected to the second ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com