Ultrathin graphite composite bipolar plate base material capable of being quickly cold-pressed and molded and preparation method thereof

A technology of cold forming and bipolar plates, which is applied in the direction of fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of short service life, failure to meet the requirements of large quantities, low strength, etc., and achieve excellent product performance, Efficient production efficiency and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

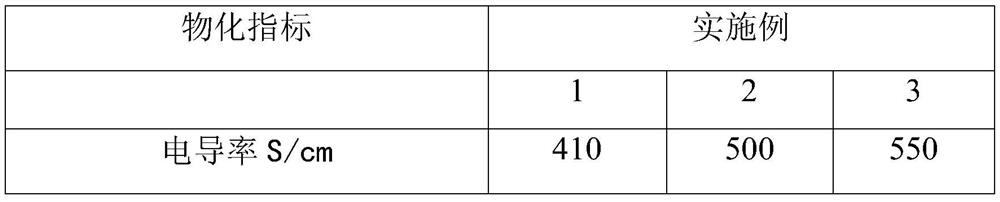

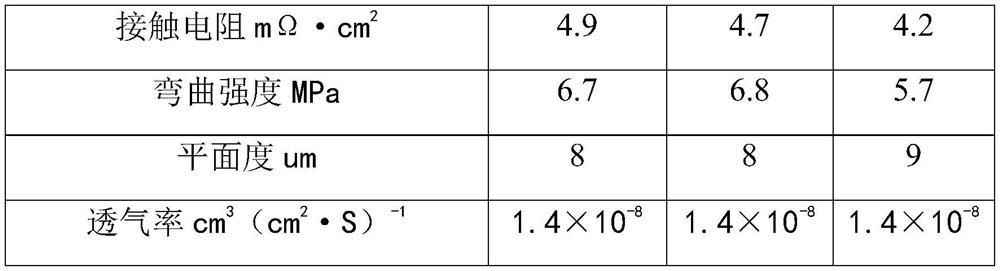

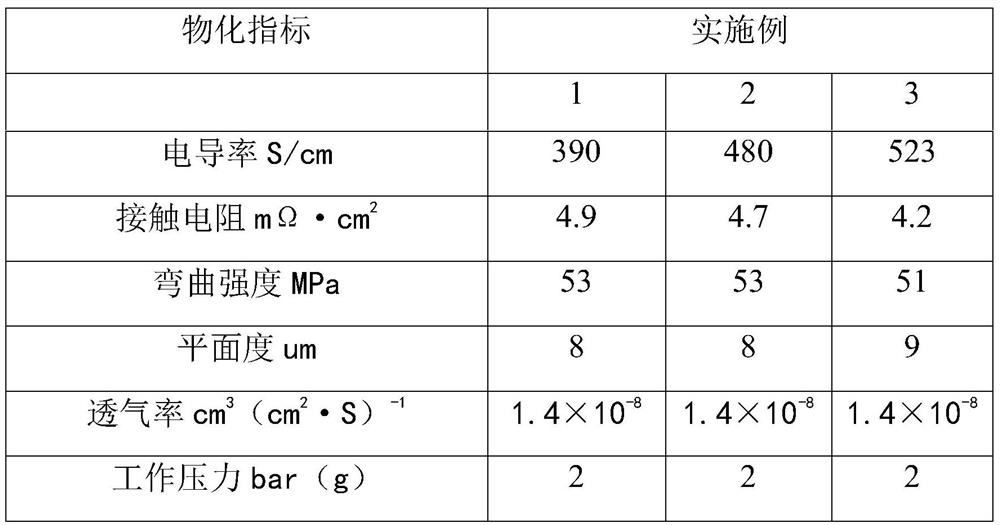

Embodiment 1

[0023] The invention provides an ultra-thin graphite composite bipolar plate base material that can be quickly cold-pressed, and its components and raw material weight percentages are:

[0024] 150 mesh ~ 200 mesh natural flake graphite powder 40%

[0025] 100-150 mesh graphite worms 20%

[0026] 200-300 mesh graphite worms 15%

[0027] Synthetic resin 23%

[0028] Surfactant 2%

[0029] In this embodiment, the graphite material is added into the dry mixer according to the proportion for mixing, and after the graphite material is mixed evenly, the surfactant is added to further mix evenly, and the vacuum equipment of the dry mixer is started, and vacuum is drawn while stirring to ensure mixing After the powder is dried, take out all the powder, put the mixed and dried powder into a 300-mesh granulator for grinding, pass through a 300-mesh sieve, and repeat the operation until all the powder passes through the 300-mesh sieve. Add the sieved graphite powder into the three-di...

Embodiment 2

[0032] The invention provides an ultra-thin graphite composite bipolar plate base material and a preparation process that can be rapidly cold-pressed. The components and weight percentages of the raw materials are:

[0033] 150 mesh ~ 200 mesh natural flake graphite powder 50%

[0034] 100-150 mesh graphite worms 15%

[0035] 200-300 mesh graphite worms 10%

[0036] Synthetic resin 23%

[0037] Surfactant 2%.

[0038] In this embodiment, the graphite material is added into the dry mixer according to the proportion for mixing, and after the graphite material is mixed evenly, the surfactant is added to further mix evenly, and the vacuum equipment of the dry mixer is started, and vacuum is drawn while stirring to ensure mixing After the powder is dried, take out all the powder, put the mixed and dried powder into a 300-mesh granulator for grinding, pass through a 300-mesh sieve, and repeat the operation until all the powder passes through the 300-mesh sieve. Add the sieved gr...

Embodiment 3

[0041] The invention provides an ultra-thin graphite composite bipolar plate base material and a preparation process that can be rapidly cold-pressed. The components and weight percentages of the raw materials are:

[0042] 150 mesh ~ 200 mesh natural flake graphite powder 60%

[0043] 100-150 mesh graphite worms 10%

[0044] 200-300 mesh graphite worms 10%

[0045] Synthetic resin 19%

[0046] Surfactant 1%.

[0047] In this embodiment, the graphite material is added into the dry mixer according to the proportion for mixing, and after the graphite material is mixed evenly, the surfactant is added to further mix evenly, and the vacuum equipment of the dry mixer is started, and vacuum is drawn while stirring to ensure mixing After the powder is dried, take out all the powder, put the mixed and dried powder into a 300-mesh granulator for grinding, pass through a 300-mesh sieve, and repeat the operation until all the powder passes through the 300-mesh sieve. Add the sieved gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com