Application of reduced graphene oxide film in frozen electron microscope

A technology of cryo-electron microscopy and graphene, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of background noise, strong conductivity, etc., and achieve the effect of convenient acquisition, good resolution, and reduction of background noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

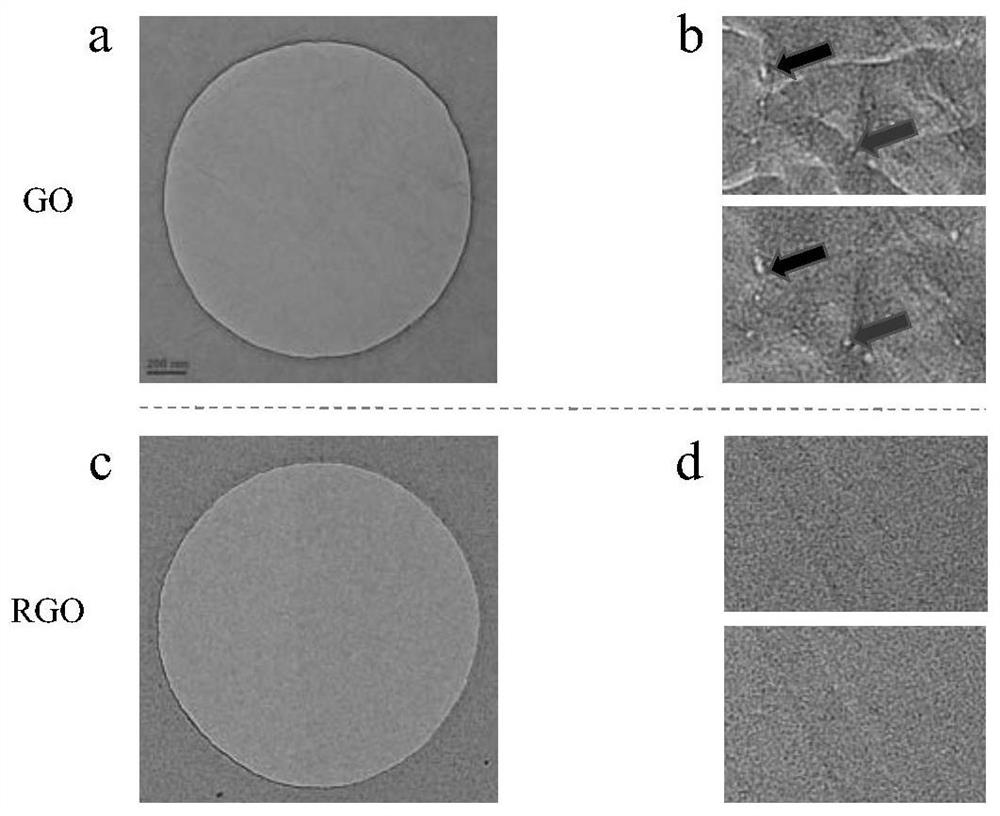

[0035] Embodiment 1, the preparation of reduced graphene oxide electron microscopy grid support film

[0036] figure 1 (a) Schematic diagram of the preparation of the reduced graphene oxide grid for electron microscopy, the principle of which is to drop the solution containing graphene oxide into a container filled with water. The liquid level of the solution is higher than the grid placed in it, and the graphene oxide floats above the liquid level. Open the water outlet valve to make the liquid level drop slowly, and the graphene oxide is then attached to the carrier net. The graphene oxide electron microscope grid is naturally dried and then reduced at a high temperature at 300°C to prepare the reduced graphene oxide electron microscope grid. The specific process is as follows:

[0037] 1. Preparation of graphene oxide

[0038] Add H at a volume ratio of 9:1 to 3 g of graphene 2 SO 4 / H 3 PO 4 Mix the solution (400ml) and 18g potassium permanganate, heat to 50°C and k...

Embodiment 2

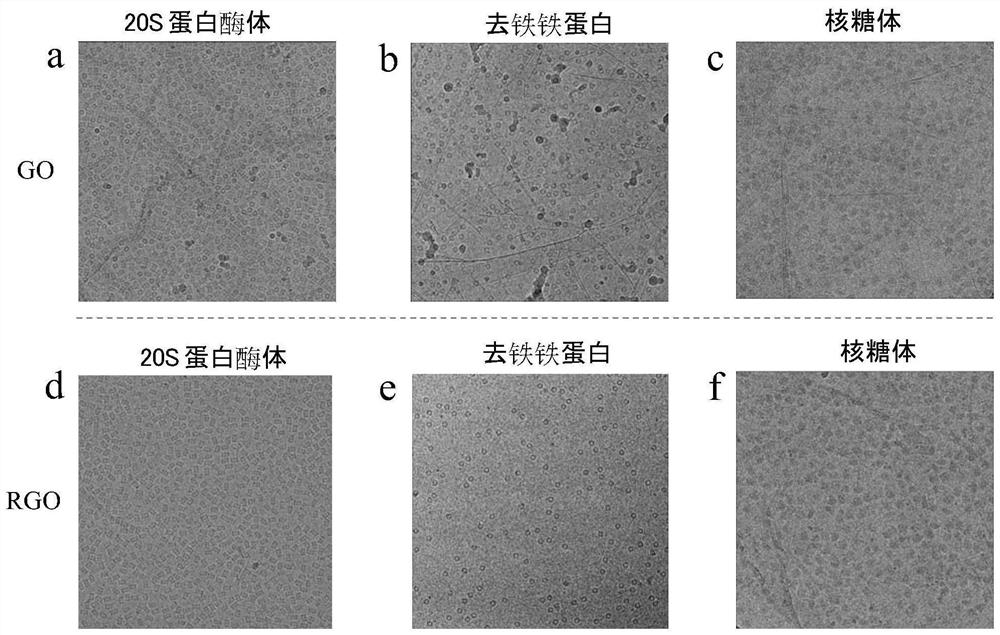

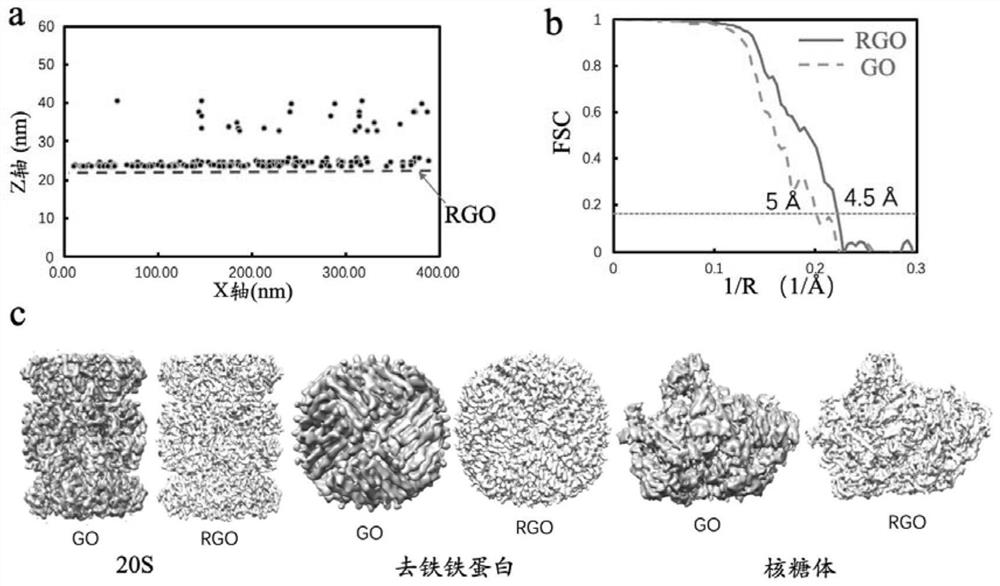

[0046] Embodiment 2, application of reduced graphene oxide electron microscope carrier network support film

[0047] Take 20S proteasome, apoferritin and ribosome as examples to make frozen samples.

[0048] First, discharge and hydrophilize the grid covering the reduced graphene oxide prepared in Example 1: the vacuuming time during the treatment is 15s, and the low-grade discharge time is 15s. Then ~4ul 20S proteasome solution was added dropwise to the support membrane of the reduced graphene oxide electron microscope grid, and then transferred to FEI Vitrobot (frozen sample preparation instrument). The humidity of the Vitrobot cavity was adjusted to 100%, and the temperature was adjusted to 12°C. The suction time of the filter paper was set to 2s, and the force was set to -2. After the excess liquid was absorbed by the filter paper clip, the grid was quickly inserted into liquid ethane so that the water on the grid was quickly frozen to form glassy ice, and then transferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com