Filter ball valve

A technology for filtering ball valves and valve bodies, which is applied in the direction of filtration and separation, valve details, and valve devices. cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

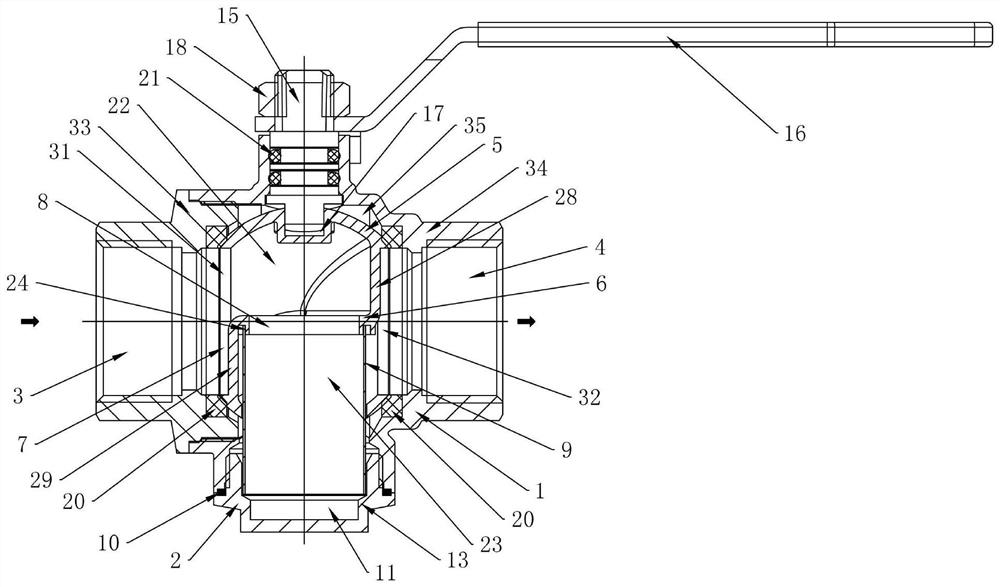

[0056] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 4 As shown, the filter screen 9 is set in a sleeve shape.

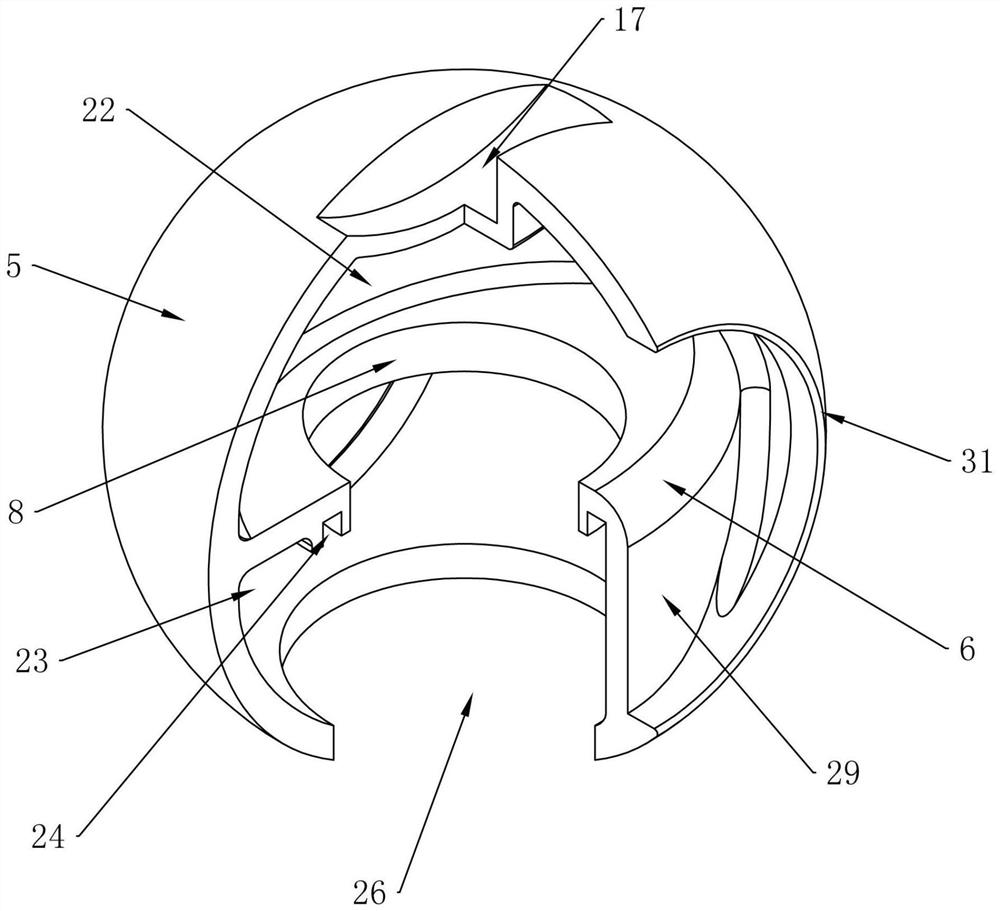

[0057] In a further embodiment of the present invention, the spool 5 includes: a sphere 27, a spacer 6, an upper connecting plate 28 and a lower connecting plate 29, the sphere 27 is a hollow structure, and one side of the sphere 27 is provided with an upper connecting plate that communicates with the inlet 3. Cavity inlet 31, the other side of spheroid 27 is provided with the lower cavity outlet 32 that is communicated with outlet 4, and flow hole 8 is offered at the spacer 6 place, and spacer 6 is located at the inside of spheroid 27, and the upper connecting plate 28 The upper end and the left and right ends are all connected with the inwall of the spheroid 27, the lower end of the upper connecting plate 28 is connected with one side of the outer edge of the shelf 6, and the lower end and the left and right end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com