Raising needling machine with net inlet having brush cleaning function

An acupuncture machine and cleaning technology, which is applied to cleaning methods and appliances, dust removal, textiles and papermaking, etc., can solve the problems of increased inspection workload, many action transmission links, and increased energy consumption, so as to reduce daily inspection. The effect of less nursing workload, fewer action transmission links, and reasonable positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to be able to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail in the form of examples below, but the description of the examples is not a limitation to the solution of the present invention. Anything made according to the concept of the present invention All equivalent transformations that are merely formal rather than substantive should be regarded as the scope of the technical solution of the present invention.

[0023] In the following description, all concepts related to the directionality or orientation of up, down, left, right, front, and back are based on the positional state of the picture, and therefore cannot be understood as providing for the present invention Special limitations of technical solutions.

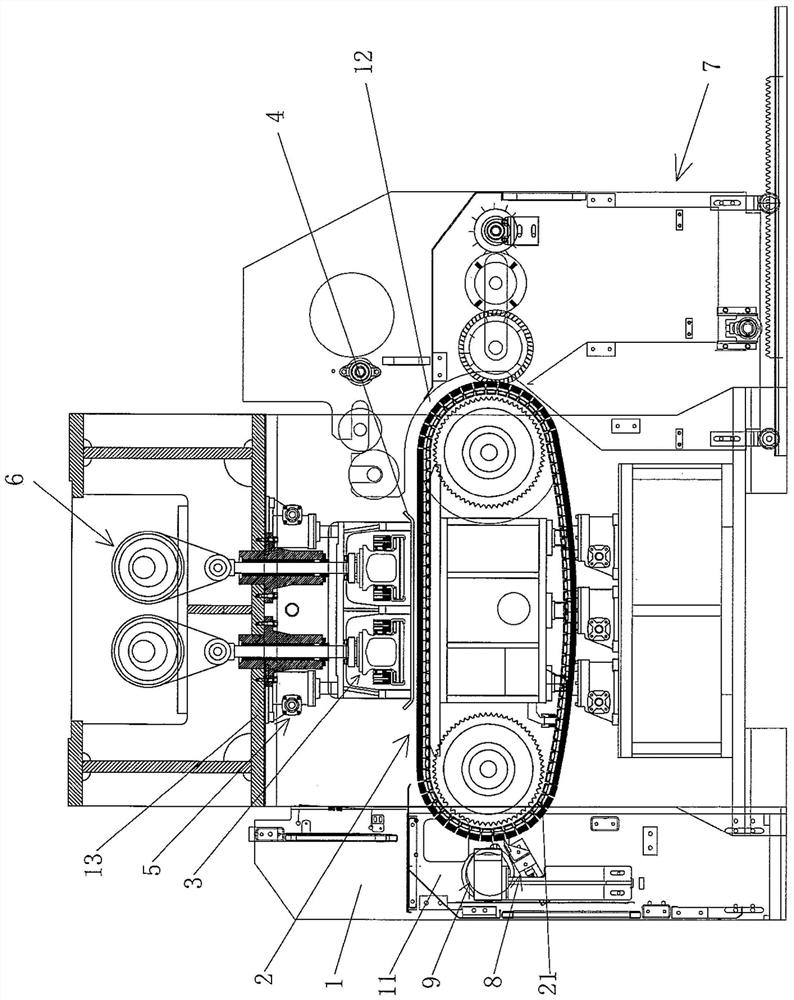

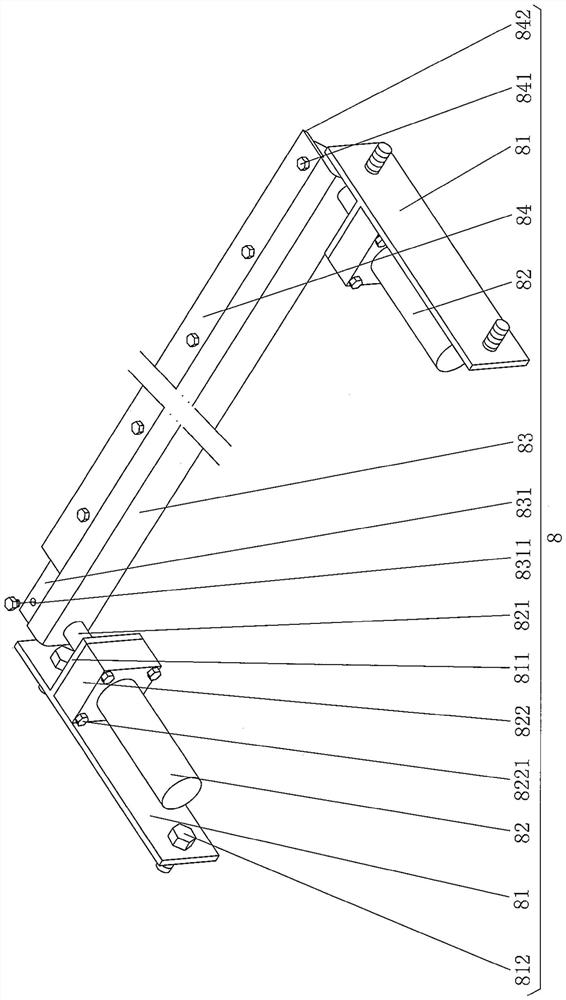

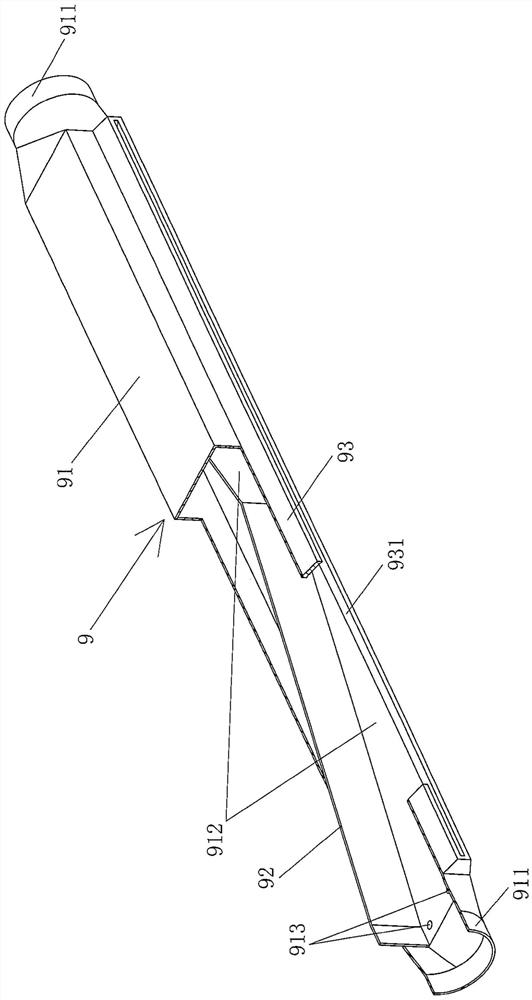

[0024] See figure 1 , Shows the frame 1, the raising mechanism 2, the needle punching mechanism 3, the stripping plate 4, the stripping plate lifting and adjusting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com