A method for forming and preparing aluminum alloy plate with high alloy content

An aluminum alloy plate and aluminum alloy technology, applied in metal rolling and other directions, can solve the problems of weakening, deformation and failure, and achieve the effect of improving strength, strength and plasticity, and omitting heat treatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

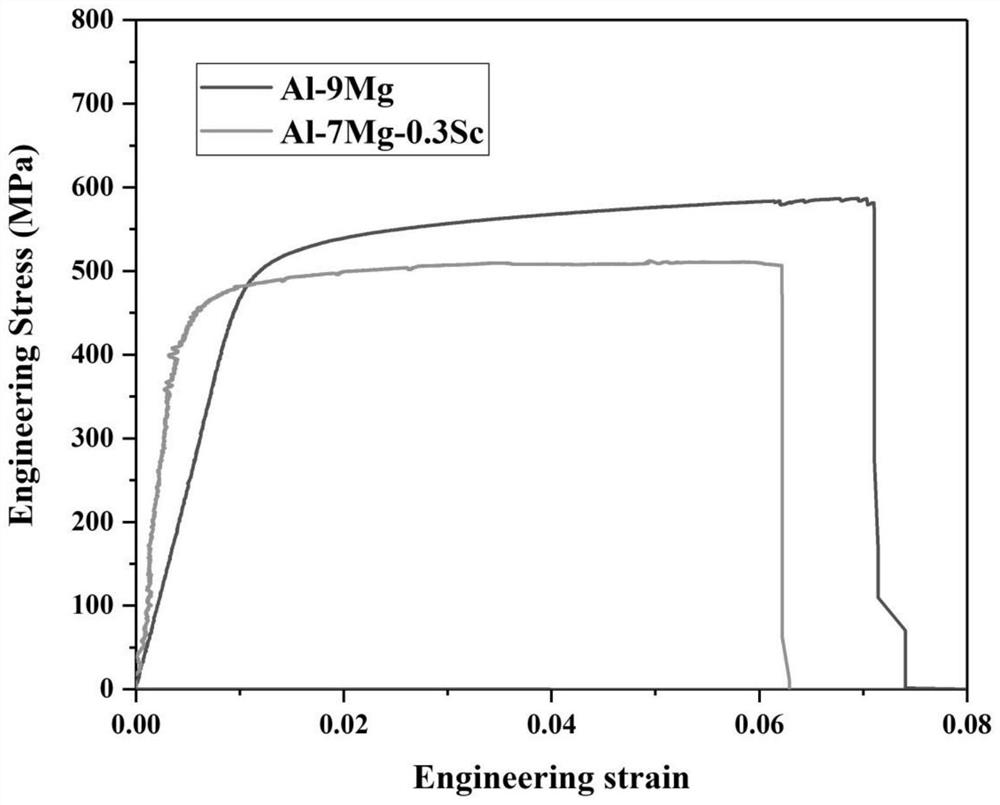

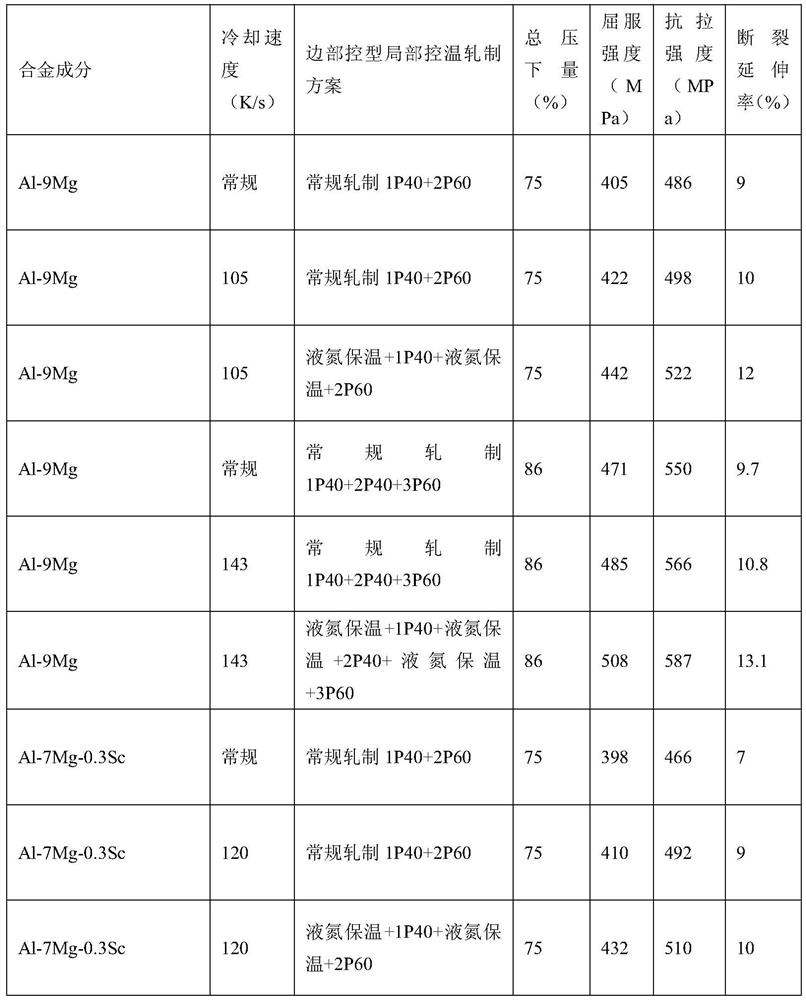

Embodiment 1

[0025] (1) Sub-rapid solidification microstructure control technology: use commercially pure aluminum and pure magnesium to prepare a cast aluminum-magnesium alloy blank (hereinafter referred to as Al-9Mg) with a magnesium content of 9wt%, and then reduce the magnesium content to 9wt% in a resistance furnace The cast aluminum-magnesium alloy blank is heated to obtain molten aluminum-magnesium alloy, and then the molten aluminum-magnesium alloy is cast in a sub-rapid water-cooled copper mold and cooled to room temperature. By adjusting the cooling water flow rate, the cooling rate is 105K / s, so that the components of the alloy are fully dissolved, and the plate after sub-rapid solidification is obtained;

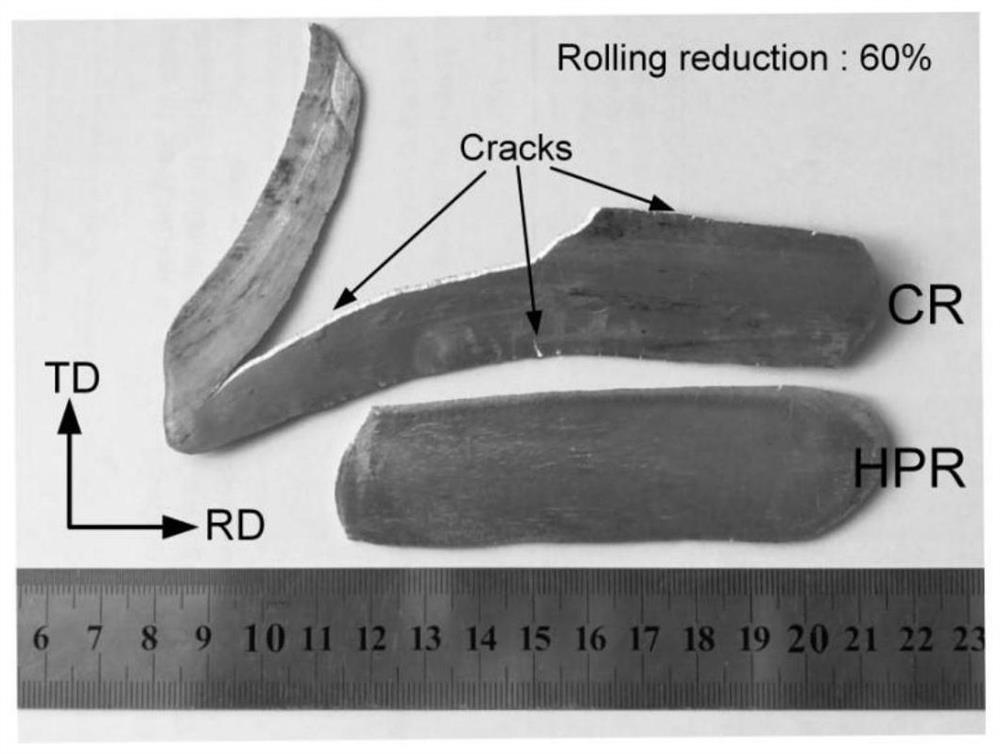

[0026] (2) Edge-controlled local temperature-controlled rolling technology: Process the plate after sub-rapid solidification in step (1) into a 20mm×40mm×5mm cuboid rolling sample, and use steel plates with a thickness of 0.9mm on the upper and lower surfaces of the sample C...

Embodiment 2

[0029] (1) Sub-rapid solidification microstructure control technology: using commercially pure aluminum and pure magnesium to prepare as-cast aluminum with a magnesium content of 9wt%-

[0030] Magnesium alloy billet (hereinafter referred to as Al-9Mg), then in the resistance furnace, the cast aluminum-magnesium alloy billet with a magnesium content of 9wt% is heated to obtain a molten aluminum-magnesium alloy, and then the molten aluminum-magnesium alloy is heated in a sub- Cast and cool to room temperature in a rapid water-cooled copper mold. By adjusting the cooling water flow rate, the cooling rate is 143K / s, so that the components of the alloy are fully dissolved, and the plate after sub-rapid solidification is obtained;

[0031] (2) Edge-controlled local temperature-controlled rolling technology: Process the plate after sub-rapid solidification in step (1) into a 20mm×40mm×5mm cuboid rolling sample, and use steel plates with a thickness of 0.9mm on the upper and lower sur...

Embodiment 3

[0034](1) Sub-rapid solidification microstructure control technology: use industrial pure aluminum, pure magnesium and aluminum-scandium master alloy to prepare as-cast aluminum-magnesium-scandium alloy material (hereinafter referred to as Al-7Mg) with a magnesium content of 7wt% and a scandium content of 0.3wt%. -0.3Sc). In the resistance furnace, the cast aluminum-magnesium-scandium alloy material with a magnesium content of 7wt% is heated to obtain the molten aluminum-magnesium-scandium alloy material, and then the molten aluminum-magnesium-scandium alloy material is heated in a sub-rapid water-cooled copper Cast in the mold and cool to room temperature. By adjusting the cooling water flow rate, the cooling rate is 120K / s, so that the components of the alloy are fully dissolved, and the plate after sub-rapid solidification is obtained;

[0035] (2) Edge-controlled local temperature-controlled rolling technology: Process the plate after sub-rapid solidification in step (1) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com