Production system and method of methionine complex metal salt

A complex metal and production system technology, applied in the production system field of methionine complex metal salt, can solve the problems of increased cost, low absorption utilization rate, environmental pollution, etc., to prevent heat loss, control temperature, and improve complexation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

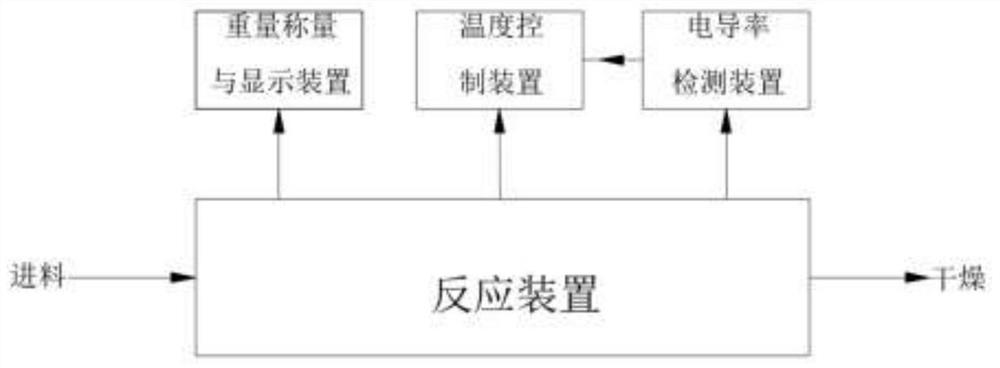

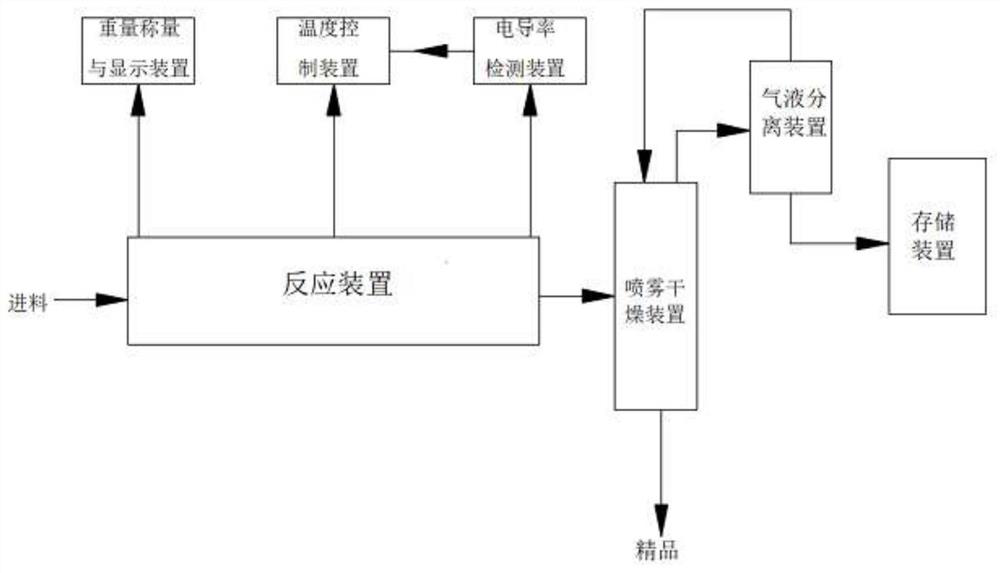

[0036] The invention provides a production system of methionine complex metal salt, referring to figure 1 , The production system includes a reaction device, a weighing and display device, a temperature control device, and a conductivity detection device. The reaction device is provided with a weight weighing and display device and a temperature control device, and the conductivity detection device is connected with the reaction device.

[0037] The material is placed in the reaction device, weighed and displayed by the weighing and display device. When a certain amount is put in, the temperature control device starts to control the heating. After dissolving for a period of time, the conductivity detection device detects that the conductivity reaches the corresponding standard. The temperature control device performs temperature control to carry out the complexation reaction, and then enters the drying device for drying after the complexation reaction.

Embodiment 2

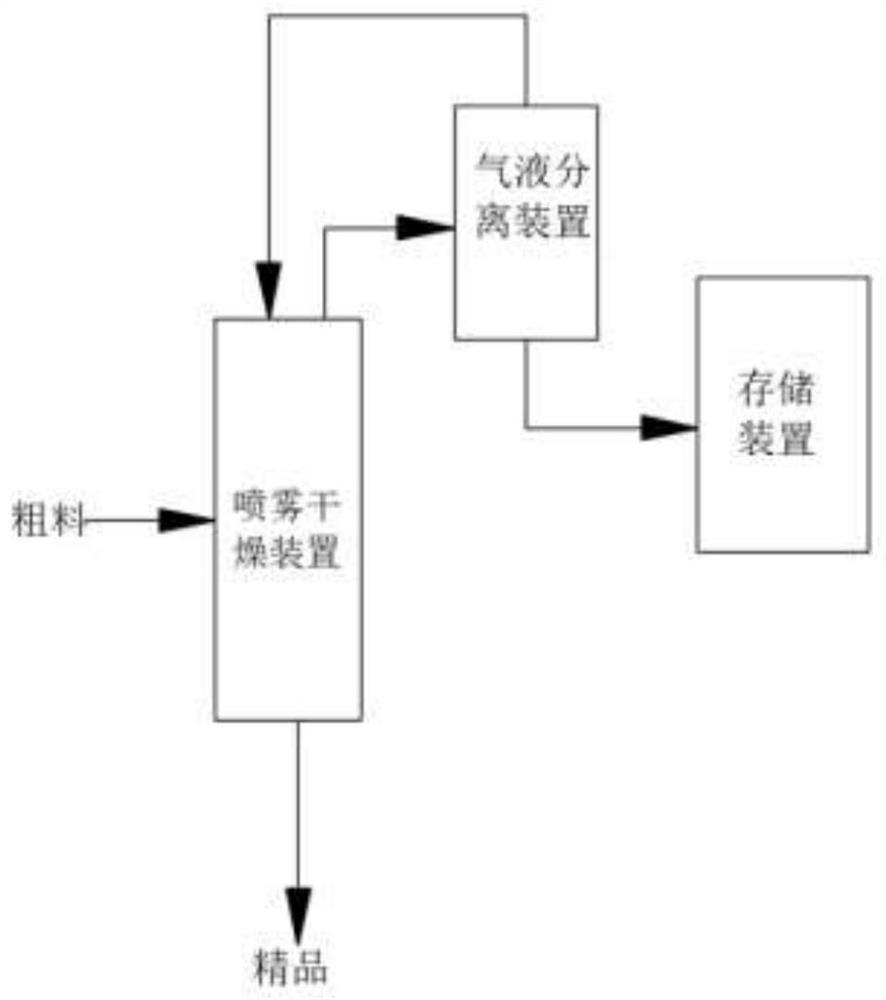

[0039] The embodiment of the present invention provides a schematic diagram of the production system of fine methionine complex metal salt, refer to figure 2 , image 3 , on the basis of Example 1, increase such as figure 2 The schematic diagram of the spray drying system is shown, and the spray drying system includes a dry spray drying device, a gas-liquid separation device and a storage device.

[0040] The methionine complex metal salt produced by the production system of methionine complex metal salt in Example 1 is a mixed solution, and the mixed solution is directly dewatered through a spray drying device to obtain a fine methionine complex metal salt, and the methionine complex metal salt discharged from the spray drying device contains The gas with a large amount of water vapor passes through the gas-liquid separation device to separate the gas and water, and then the gas is passed into the spray drying device for recycling, and the condensed water is stored in the ...

Embodiment 3

[0042] (1) Raw material delivery

[0043] In the reactor of 1000L, add the methionine crystal (2000 moles) of 151.66kg content 99wt% and the deionized water of 300kg, be warming up to 65 ℃ then, add the manganese sulfate tetrahydrate 450.63kg (2000kg) of content 99wt% under the state of stirring Moore).

[0044] (2) Complexation reaction between methionine and manganese salt

[0045] The conductivity detector detects that the conductivity is 20x10 -2 S.cm -1 , immediately raised the temperature to 78° C., and kept the temperature for 1.5 hours to obtain a concentration of methionine complex metal salt of 49.89 wt%.

[0046] (3) Spray drying treatment of methionine complex metal salt

[0047]Concentrate the mixed material liquid obtained above in the reactor, circulate the condensed water to the next batch of production water, concentrate the reaction mixed liquid to a concentration of 80wt%, have good fluidity at 80°C, and then spray dry it treatment, the nitrogen preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com