Compression method for t-shaped and/or i-shaped stringers of composite material reinforced panels

A technology for reinforced wall panels and composite materials, which is applied in the field of T-shaped and/or I-shaped truss pressurization of composite reinforced wall panels, can solve the problem of uneven pressure transmission, high tooling cost, fabric prepreg and Airpad rubber procurement cycle is long and other problems, to achieve the effect of reducing tooling input costs, improving product yield, and shortening delivery cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

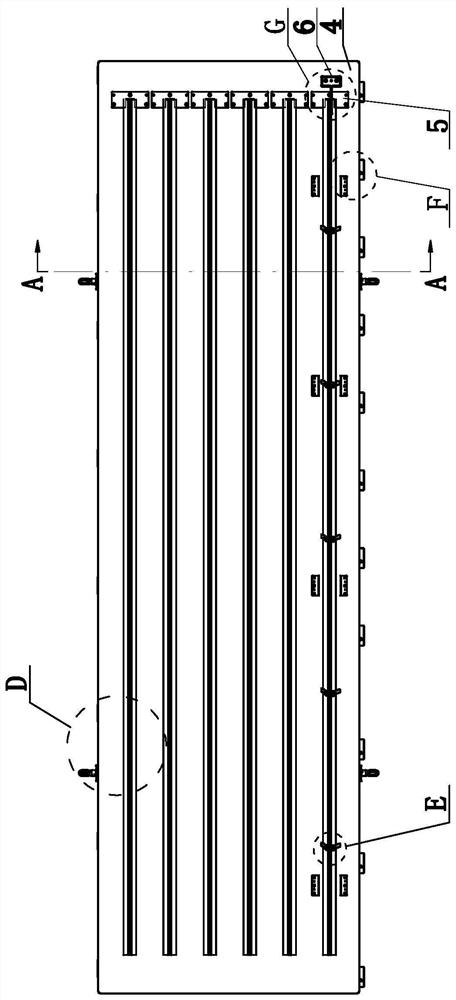

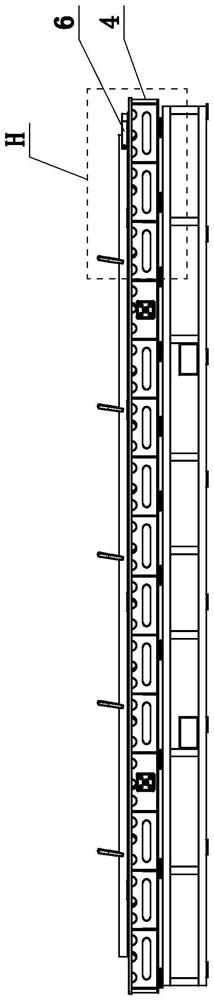

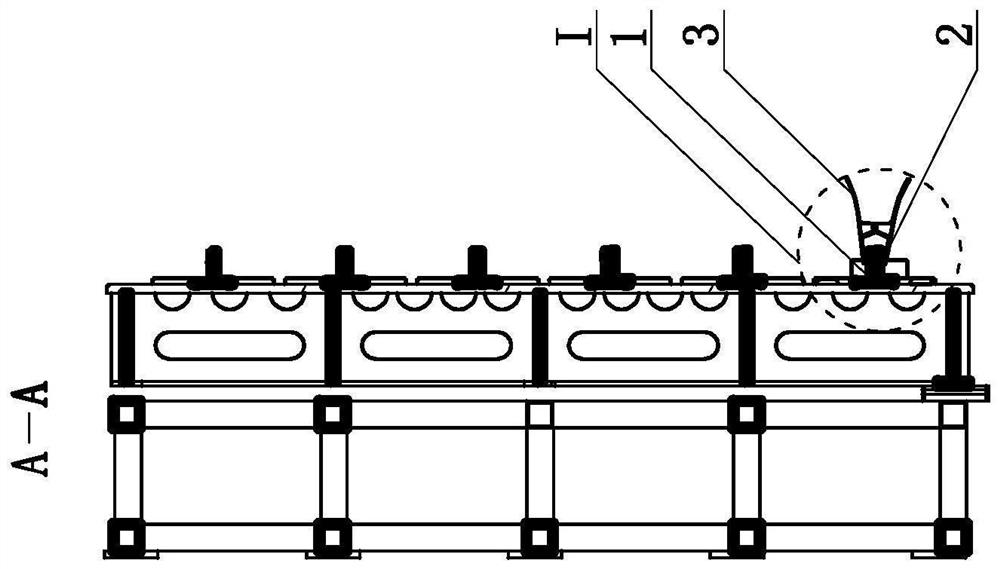

[0033] Specific implementation mode one: as Figure 1-Figure 18 As shown, this embodiment discloses a method for pressing a T-shaped and / or I-shaped long stringer of a composite material reinforced wall panel, and the method includes the following steps:

[0034] Step 1: firstly transfer the stringer preform to the curing tool 4, the two sides of the stringer preform are positioned by positioning piece 1 5, and one end of the stringer preform in the length direction is positioned by positioning piece 2 6 Positioning, the first positioning part 5 and the second positioning part 6 are all detachably and fixedly connected with the curing tooling (through screws); the shape of the long stringer preform is T-shaped and / or I-shaped;

[0035] Step 2: Encapsulate; place an isolation film on the surface of the stringer preform, and when the stringer preform is T-shaped, place an L-shaped soft film 1 on both sides of the T-shaped stringer preform, and then place the T-shaped The truss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com