Pellet coating equipment and pellet coating process

A micropellet coating and equipment technology, applied in lighting and heating equipment, other household appliances, household components, etc., can solve the problems that affect the production efficiency of drug product stability, affect the drying effect and the uniformity of drug application, and achieve good results The uniformity of spraying, the improvement of the uniformity of spraying, and the effect of good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

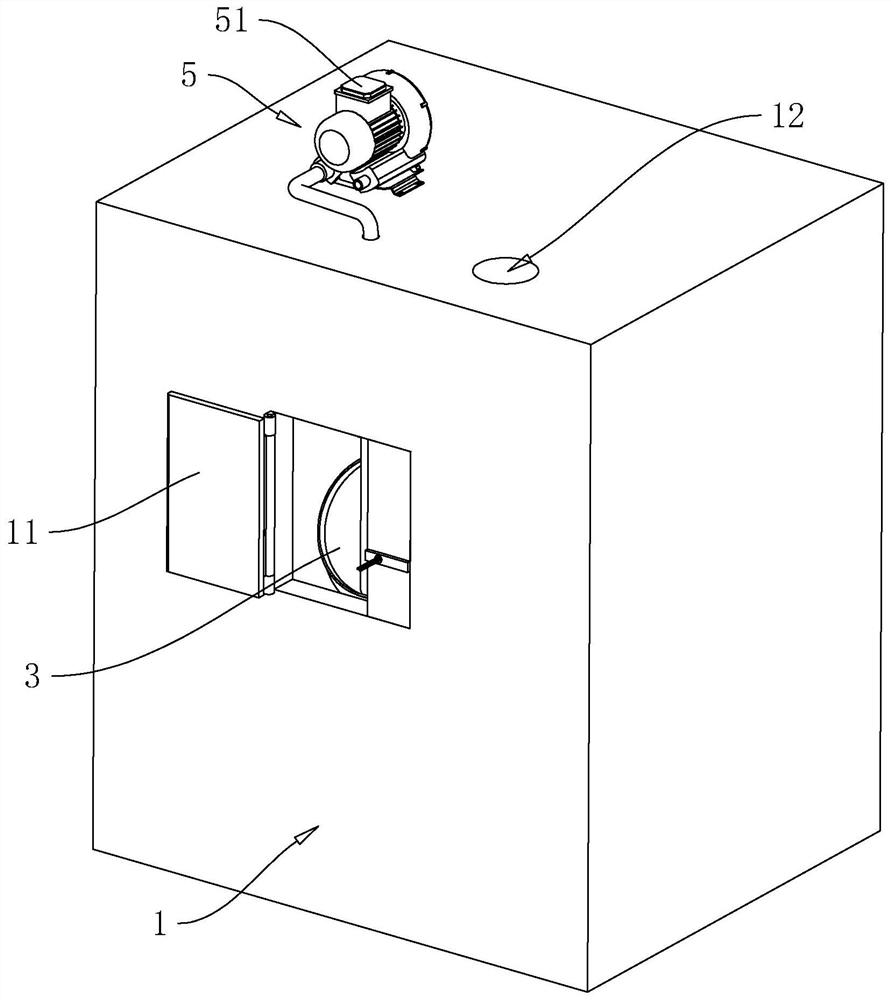

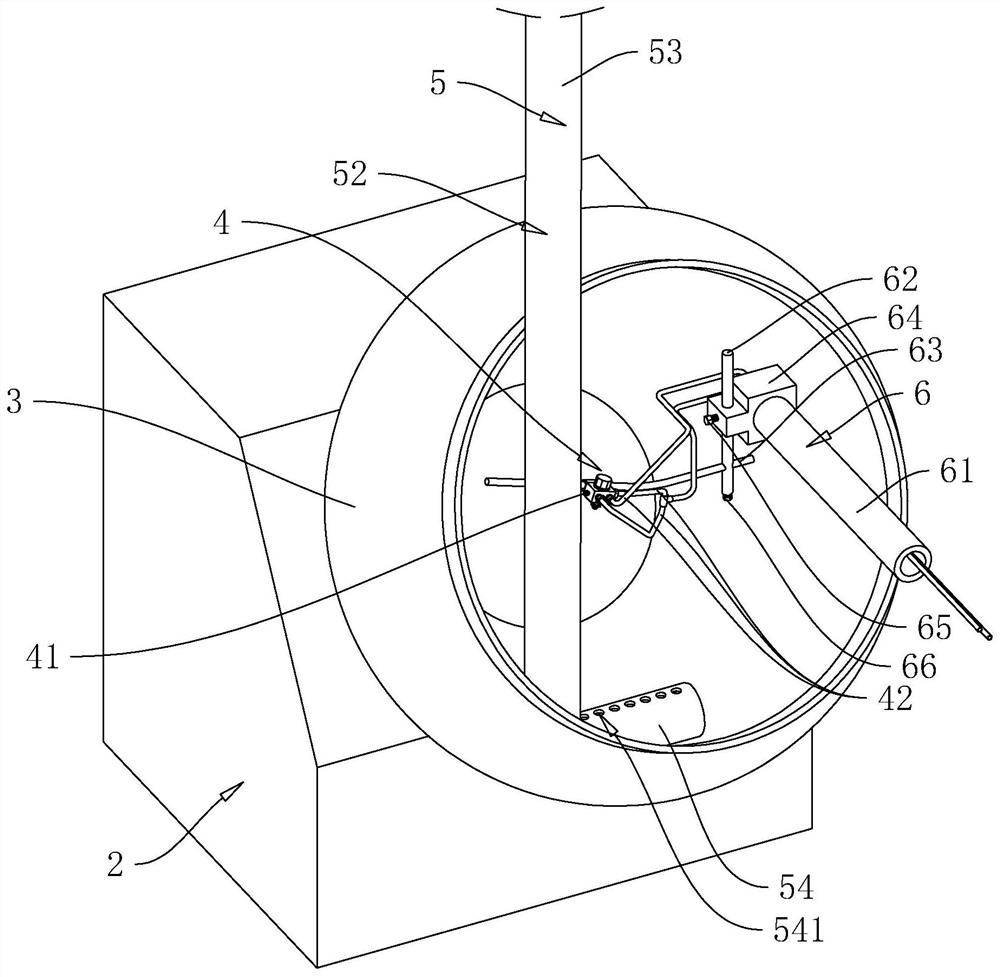

[0043] Example 1: A pellet coating equipment, such as figure 1 As shown, it includes a hollow outer shell 1, a support frame 2 and a pot body 3 arranged in the outer shell 1, a spraying mechanism 4 for spraying the pellets and a drying mechanism 5 for drying the pellets (see figure 2 ). An opening and closing door 11 is opened on the vertical surface of the outer shell 1 facing the pot body 3 to facilitate sealing and observing the coating state.

[0044] Such as figure 2 As shown, the support frame 2 is placed in the outer shell 1, and the pot body 3 is rotatably connected to the support frame 2 and can rotate on the support frame 2. The pot body 3 is in the shape of a water chestnut, from the upper end to the lower end, the pot body 3 is inclined to the side close to the opening and closing door 11.

[0045] The spraying mechanism 4 includes an atomizing head 41 arranged in the pot 3, a drug delivery tube 42 communicating with the atomizing head 41, and a mounting frame 6 for i...

Embodiment 2

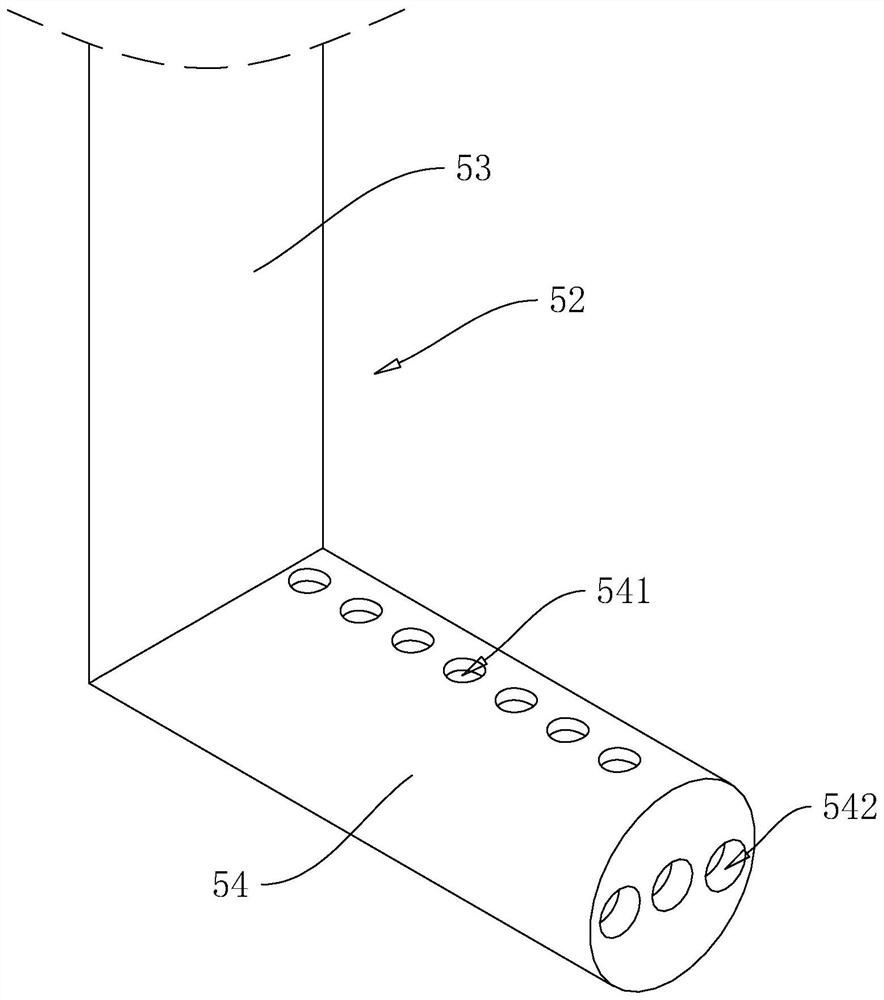

[0050] Example 2: A pellet coating equipment, which differs from Example 1 in that: image 3 As shown, a second drying port 542 is opened on the end surface of the drying tube 54 away from the connecting tube 53.

Embodiment 3

[0051] Example 3: A pellet coating equipment, which differs from Example 2 in that: Figure 4 As shown, the angle between the second drying opening 542 and the horizontal plane is 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com