Positive plate and lithium ion battery containing positive plate

A lithium-ion battery, positive electrode technology, applied in the direction of positive electrode, battery electrode, secondary battery, etc., can solve the problems of high temperature internal resistance increase, cycle performance degradation, etc., to slow down the exothermic reaction, avoid short-circuit discharge, and improve the cycle. The effect of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing the above positive electrode sheet, the method comprising the following steps:

[0060] Prepare the safety coating slurry and the positive electrode active material layer slurry respectively, wherein the safety coating includes the first positive electrode active material, the first conductive agent and the first binder; the first positive electrode active material is selected from high Nickel ternary cathode material and lithium cobalt oxide material;

[0061] The positive electrode sheet is prepared by coating the safety coating slurry and the positive electrode active material layer slurry on the positive electrode current collector by coating equipment, drying, cutting, and sheeting.

[0062] According to the present invention, described method specifically comprises the following steps:

[0063] (1-1) Mix the first positive electrode active material, the first conductive agent and the first binder, then ad...

Embodiment 1

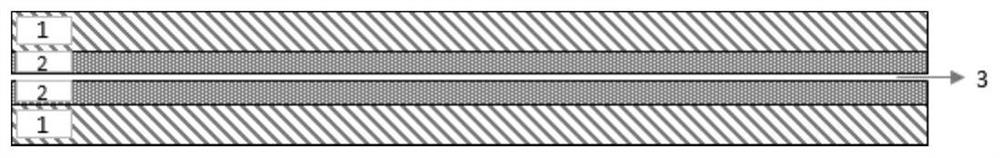

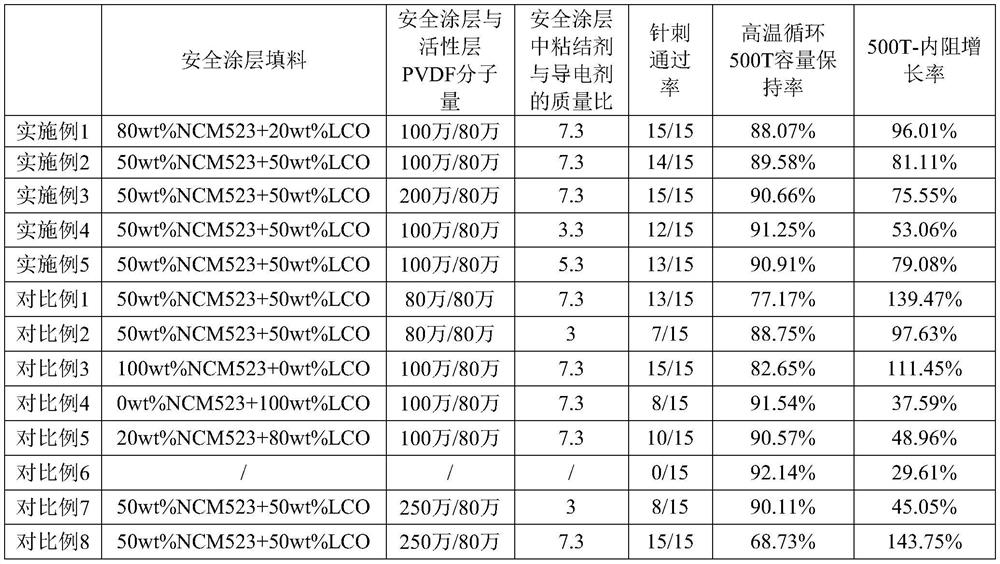

[0077] (1) Mix positive electrode active material (80wt% NCM523+20wt% LCO): polyvinylidene fluoride (molecular weight between 1 million and 1.1 million, denoted as 1 million): conductive carbon black in a mass ratio of 90:8.8:1.2 , add it to NMP, use a ball mill to stir evenly at high speed, use a coater to coat it on an aluminum foil with a thickness of 10 μm, and dry to remove NMP to obtain figure 1 Lithium-ion battery current collectors with medium safety coating, aluminum foil, and safety coating. The thickness of a single layer of security coating is about 15 μm.

[0078] (2) The above-mentioned lithium-ion battery current collector with safety coating is coated with positive electrode slurry on both sides, and the positive electrode slurry is composed of 97.5wt% lithium cobaltate (LCO), 1.1wt% polyvinylidene fluoride ( Molecular weight is between 800,000-900,000, denoted as 800,000) and 1.4wt% conductive carbon black, the positive electrode sheet that is cut into 65mm *...

Embodiment 2

[0080] Others are the same as in Example 1, except that the mass ratio of NCM523 and LCO in step (1) is 50wt% NCM523+50wt% LCO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com